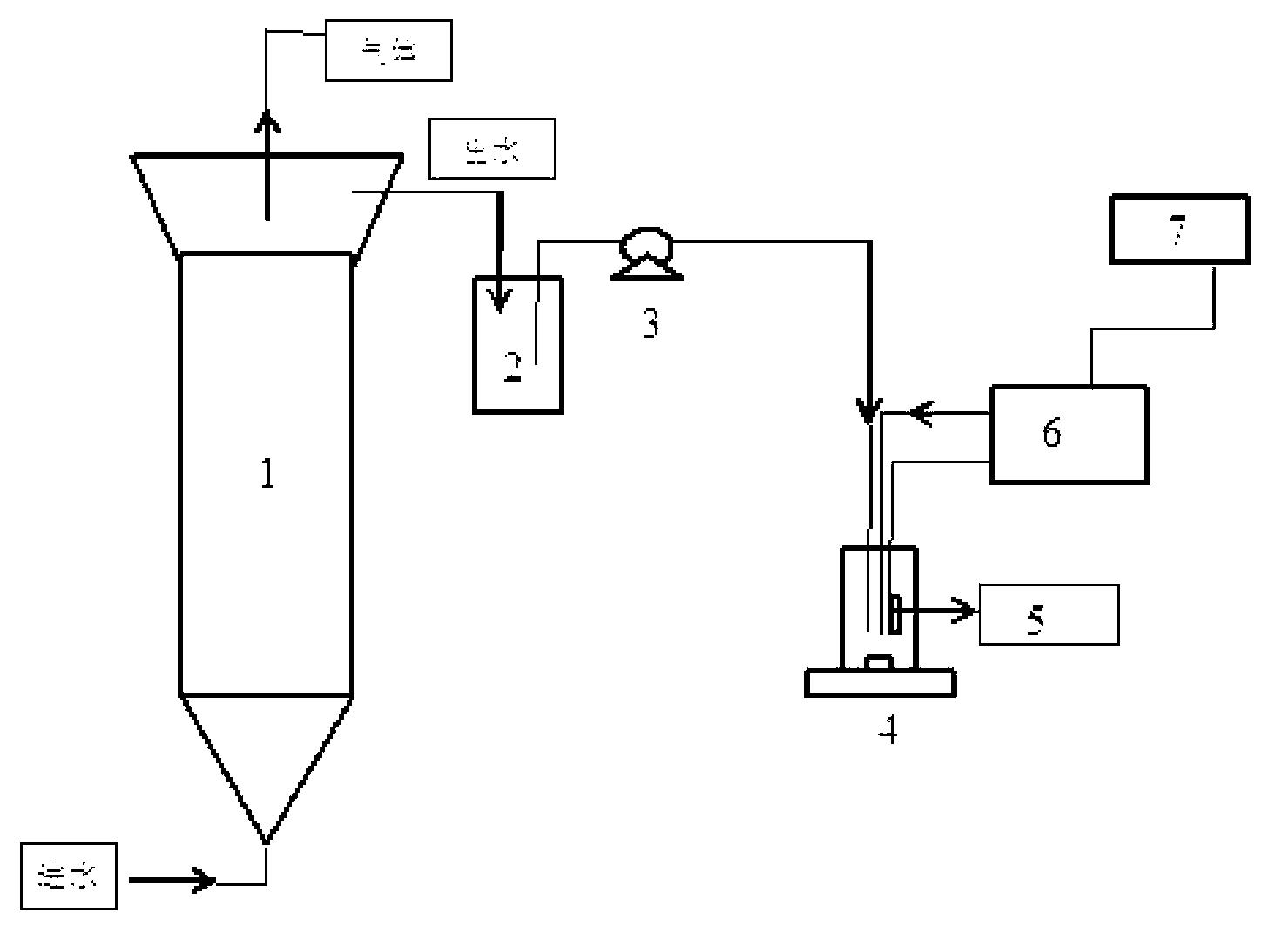

Method for rapidly determining volatile fatty acid concentration in anaerobic reactor

A volatile fatty acid, anaerobic reactor technology, applied in the direction of chemical analysis by titration, can solve the problems of decreasing measurement accuracy and increasing experimental complexity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0059] At room temperature, 0.04 L of effluent from artificial synthesis reactors with phosphate concentrations of 0, 1, 3, and 6 mM and acetic acid concentrations of 5 mM were respectively configured.

[0060] ① Under the conditions of electromagnetic stirring at 300rpm and a drop rate of 0.7mL / min, add hydrochloric acid solution with a concentration of 0.05M to the effluent with a phosphate concentration of 0mM until the pH is 4.7, and record the volume at this time (V 0 =42.15*10 -3 L). Continue to titrate with 0.05M hydrochloric acid solution until the pH of the system is 4.2, and the amount of hydrochloric acid is V x =9.85*10 -4 L, the process takes up to 20 minutes.

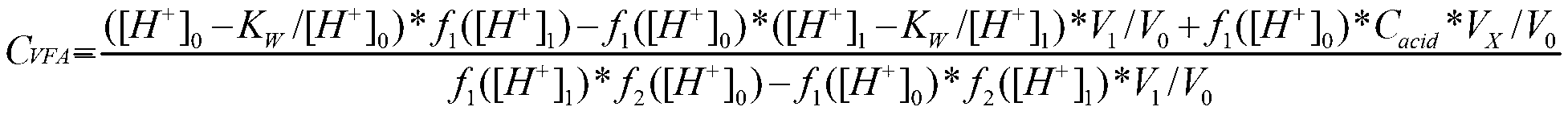

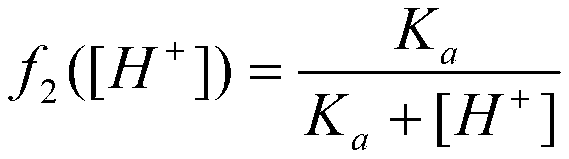

[0061] With the calculation formula of the present invention:

[0062] C VFA = ( [ H + ] ...

Embodiment 2

[0074] At room temperature, respectively configure 0.04 L of artificially synthesized reactors with ammonium salt concentrations of 0, 1.5, 3, and 4 mM and acetic acid concentrations of 1 mM.

[0075] ① Under the conditions of electromagnetic stirring at 300rpm and a drop rate of 0.7mL / min, add hydrochloric acid solution with a concentration of 0.05M to the effluent with an ammonium salt concentration of 0mM until the pH is 4.7, and record the volume at this time (V 0 =40.53*10 -3 L); continue to titrate with a hydrochloric acid solution with a concentration of 0.05M until the pH of the system is 4.2, and the amount of hydrochloric acid is V x =2.16*10 -4 L, the process takes up to 20 minutes.

[0076] With the calculation formula of the present invention:

[0077] C VFA = ( [ H + ] ...

Embodiment 3

[0089] At room temperature, 0.04L of effluent from artificial synthesis reactors with sulfide ion concentrations of 0, 1, 3, and 6mM and acetic acid concentration of 1mM were respectively configured.

[0090] ① Under the conditions of electromagnetic stirring at 300rpm and a drop rate of 0.7mL / min, add hydrochloric acid solution with a concentration of 0.05M to the effluent with an ammonium salt concentration of 0mM until the pH is 4.7, and record the volume at this time (V 0 =40.54*10 -3 L); continue to titrate with a hydrochloric acid solution with a concentration of 0.05M until the pH of the system is 4.2, and the amount of hydrochloric acid is V x =2.23*10 -4 L, the process takes up to 20 minutes.

[0091] With the calculation formula of the present invention:

[0092] C VFA = ( [ H + ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com