High-performance rechargeable magnesium battery and manufacturing method thereof

A high-performance, magnesium battery technology, used in battery electrodes, secondary batteries, sustainable manufacturing/processing, etc., can solve problems such as poor cycle performance and deactivation, and achieve high operating voltage, large specific capacity, and cycle performance. Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Fabrication of Molybdenum Disulfide Cathode

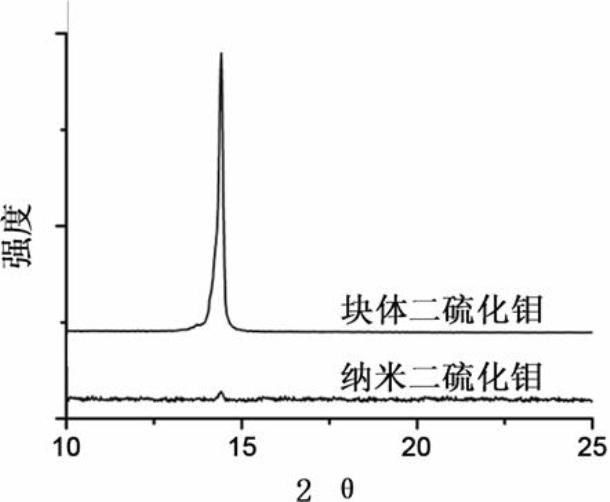

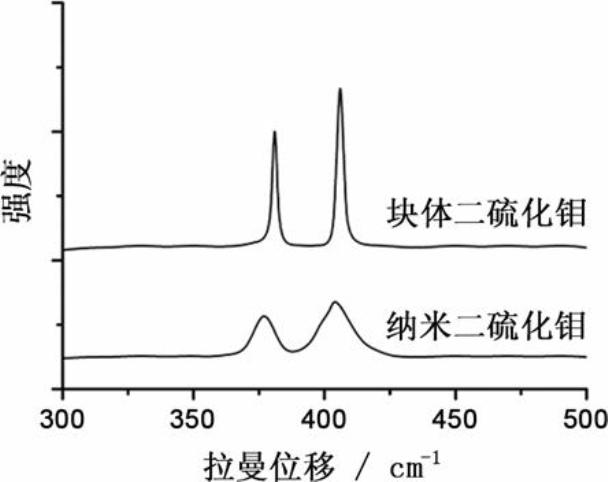

[0036] Add 0.25 mmol of molybdenum trioxide, 1 mmol of thioacetamide and 12 mL of pyridine to the hydrothermal kettle in sequence. After mixing evenly, the hydrothermal kettle was sealed and kept at 150° C. for 16 hours, then naturally cooled to room temperature. After centrifugation, the gray-black product obtained was washed several times with absolute ethanol and distilled water, and finally dried in vacuum at 60 °C for 4 hours. The X-ray diffraction pattern shows that the diffraction peak signal corresponding to the 002 crystal plane of the prepared nano-molybdenum disulfide is very weak, indicating that it has a highly exfoliated structure ( figure 1 ). The Raman spectrum shows that the prepared nano molybdenum disulfide is at 1400 cm -1 Nearby corresponds to E 1 2g and A 1g The vibrational peaks of the soften and broaden, indicating that the average number of layers is not more than 4 layers ( figure 2 ).

[0...

Embodiment 2

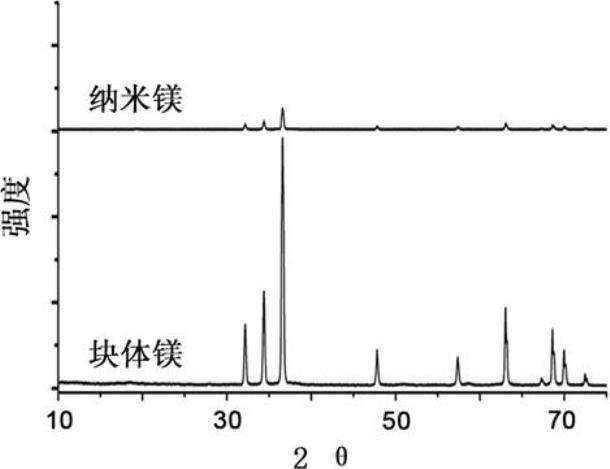

[0044] The making of the molybdenum disulfide positive electrode sheet is the same as in Example 1. The fabrication of the magnesium negative electrode is similar to that of Example 1, but the bulk magnesium is used instead of nano-magnesium, and the mass of the bulk magnesium on the electrode sheet is 3.0 mg. The assembly and testing of the simulated battery are the same as in Example 1. Image 6 It is the first constant current charge and discharge curve of the battery, the discharge platform is around 1.8 V, and the discharge capacity is 85 mAh g -1 , the first Coulombic efficiency is 0.98. The discharge capacity of the battery decays slowly in the first 15 weeks, and then accelerates the decay.

Embodiment 3

[0046] The fabrication of the molybdenum disulfide positive electrode sheet was similar to that in Example 1, but the highly exfoliated nano-molybdenum disulfide was replaced by bulk molybdenum disulfide, and the mass of the bulk molybdenum disulfide on the electrode sheet was 3.0 mg. The making of magnesium negative electrode is the same as embodiment 1. The assembly and testing of the simulated battery are the same as in Example 1. Figure 7 It is the first constant current charge and discharge curve of the battery, the discharge platform is around 1.8 V, and the discharge capacity is 71 mAh g -1 , the first Coulombic efficiency is 0.94.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average thickness | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| Area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com