Novel stirring station

A mixing station, a new type of technology, applied in mixing plants, cement mixing devices, control devices, etc., can solve the problems of restricting the quality of construction projects, high equipment investment, restricting the improvement of user construction capabilities and technical levels, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

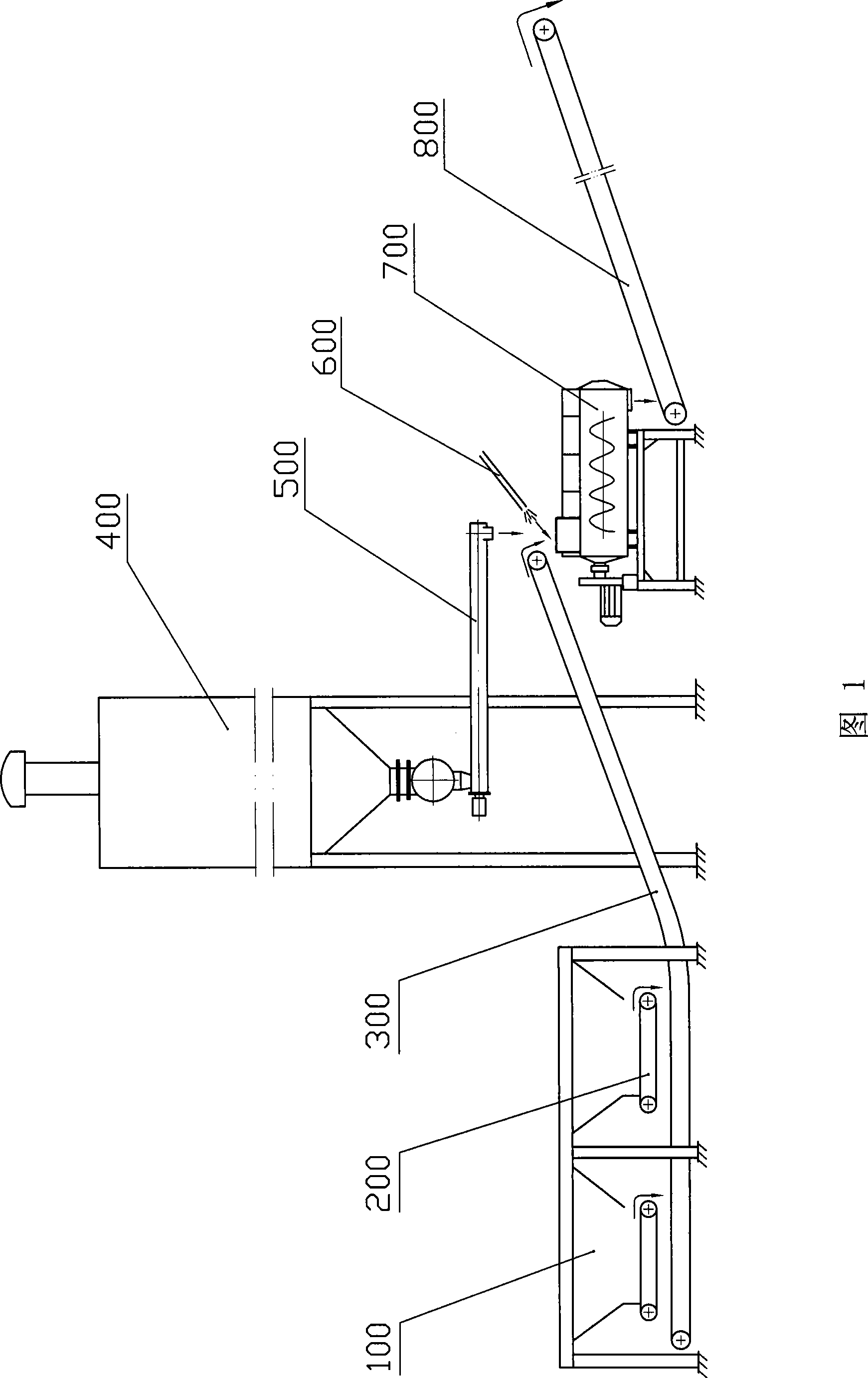

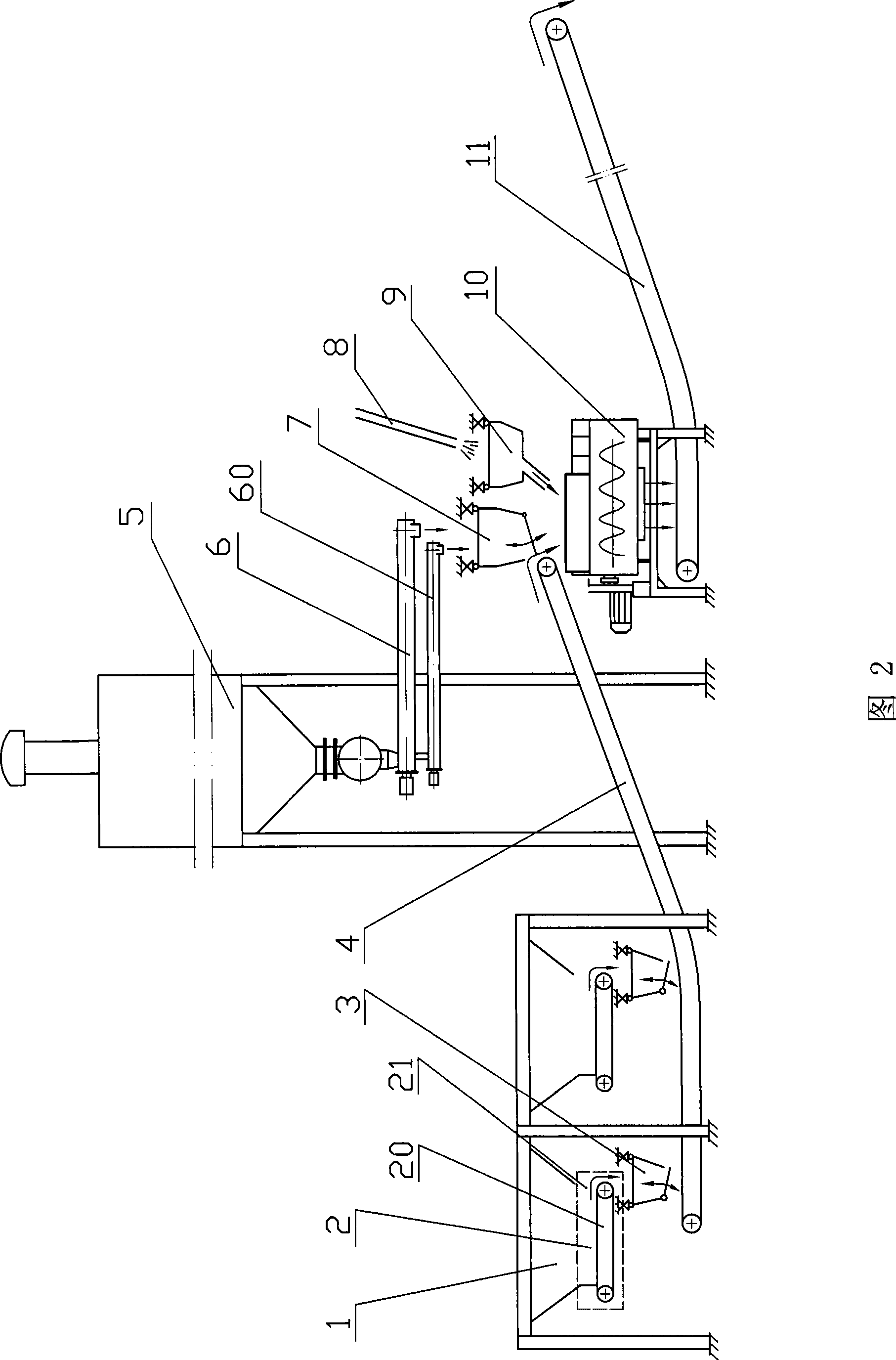

[0038] Referring to Fig. 2, the present invention includes an aggregate batching bin 1, a variable feeding system 2, an aggregate weighing hopper 3, an aggregate belt conveyor 4, a cement storage bin 5, a cement conveyor 6, a cement weighing hopper 7, and a water pump 8. Water weighing bucket 9, mixing tank 10 and discharge belt conveyor 11.

[0039]The bottom of the aggregate batching bin 1 is provided with a material outlet 21, the variable feeding system 2 is arranged below the outlet 21 of the aggregate batching bin 1, and the aggregate weighing hopper 3 is arranged under the variable feeding system 2. The material belt conveyor 4 is arranged below the aggregate weighing hopper 3, and the mixing tank 10 is arranged below the aggregate belt conveyor 4. A cement screw conveyor 6 is arranged below the cement storage bin 5 , and a cement weighing bucket 7 is arranged below the cement screw conveyor 6 . A water weighing bucket 9 is arranged below the water pump 8, and the mixi...

no. 2 example

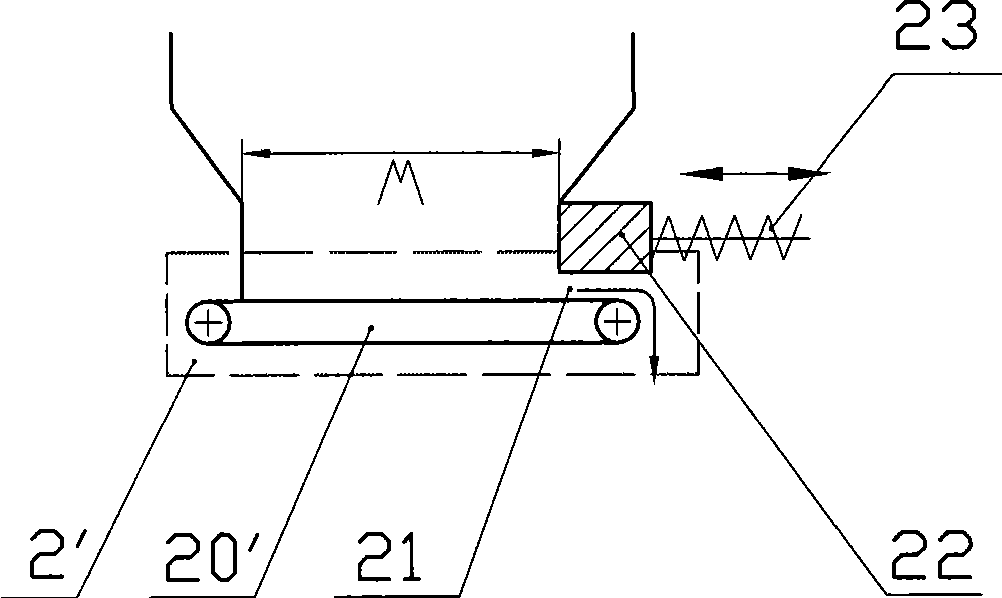

[0046] Such as image 3 As shown, the difference between the second embodiment and the first embodiment is that the feeding belt conveyor 20' in the second embodiment is a feeding belt conveyor rotating at a uniform speed, and a discharge port 21 of the aggregate batching bin 1 is provided with a The movable material door 22, the variable feeding system 2' includes the feeding belt conveyor 20' and the material door 22, the material door 22 is connected with the screw rod 23, the screw rod 23 is controlled by the motor, and the screw rod 23 controls the material door 22 in the horizontal direction, thereby changing the opening width W of the discharge port 21 in the horizontal direction. When working, the material gate 22 moves to the right along the horizontal until the width W of the discharge port 21 reaches the maximum. Moving to the left, the opening width W gradually becomes smaller, thereby controlling the batching discharge speed, and slowly sending the batching into t...

no. 3 example

[0048] Such as Figure 4 As shown, the difference between the third embodiment and the second embodiment is that the material door 22' in the third embodiment is arranged vertically and can move in the vertical direction, thereby changing the vertical direction of the discharge port 21 The opening height H above. When working, the material gate 22 moves vertically upwards along the discharge port 21 until the opening height H reaches the maximum. 22' moves vertically downwards, and the height H of the discharge port gradually decreases, so as to control the discharge speed of the ingredients, and slowly send the ingredients into the aggregate weighing hopper 3 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com