High-performance concrete mixing station

A high-performance concrete and mixing plant technology, which is used in mixing plants, mixing operation control, clay preparation devices, etc. The effect of easy transfer, small footprint and low total power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

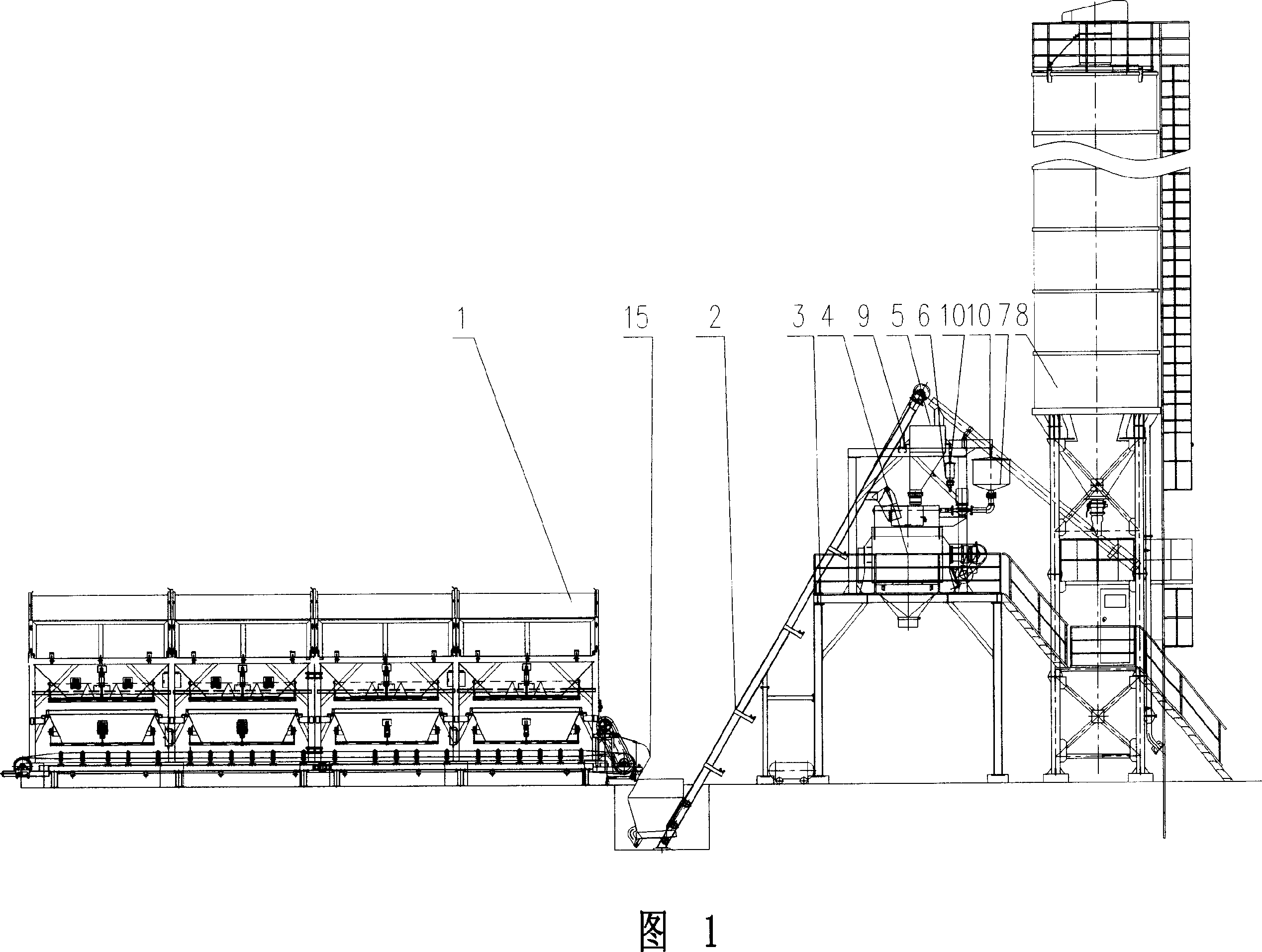

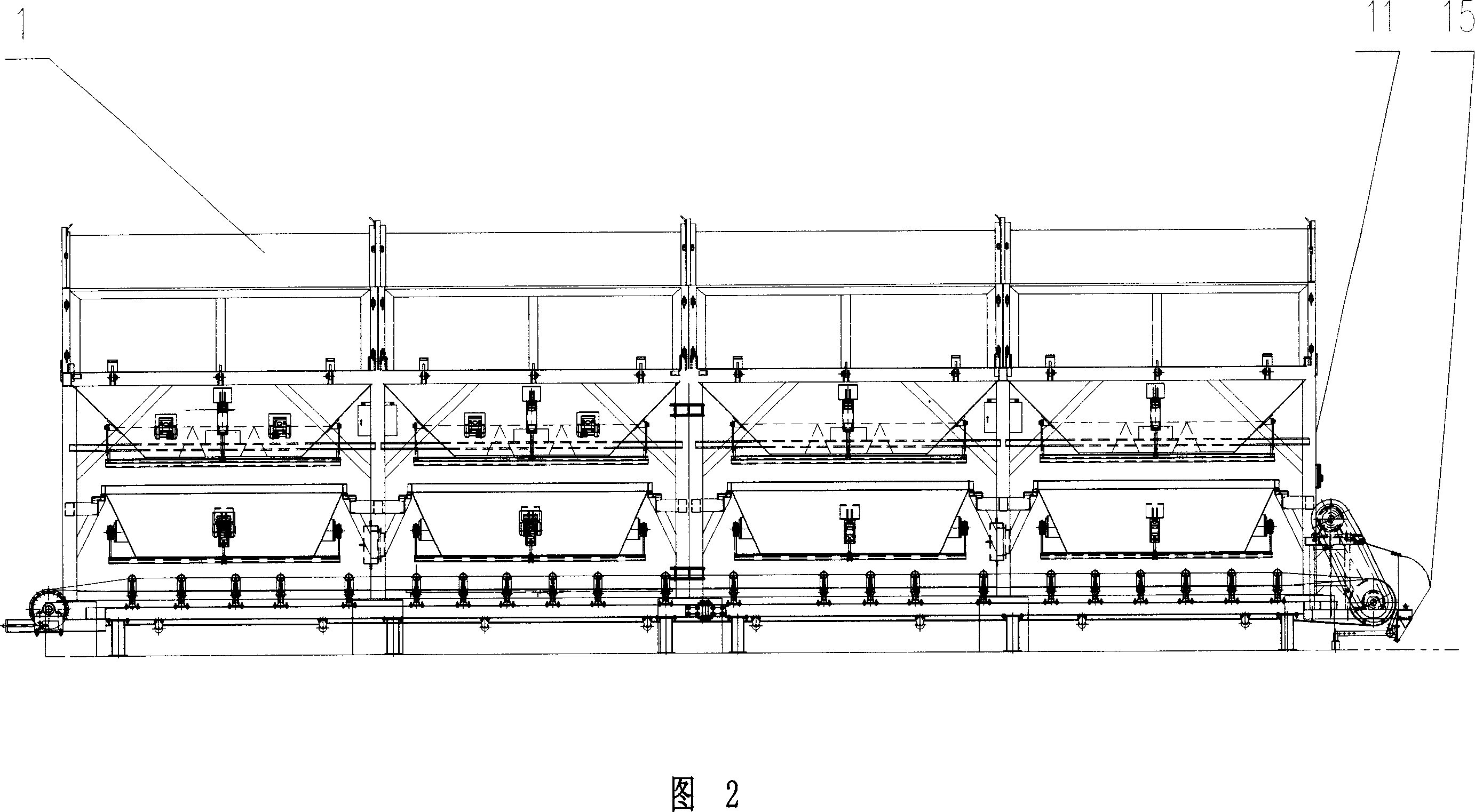

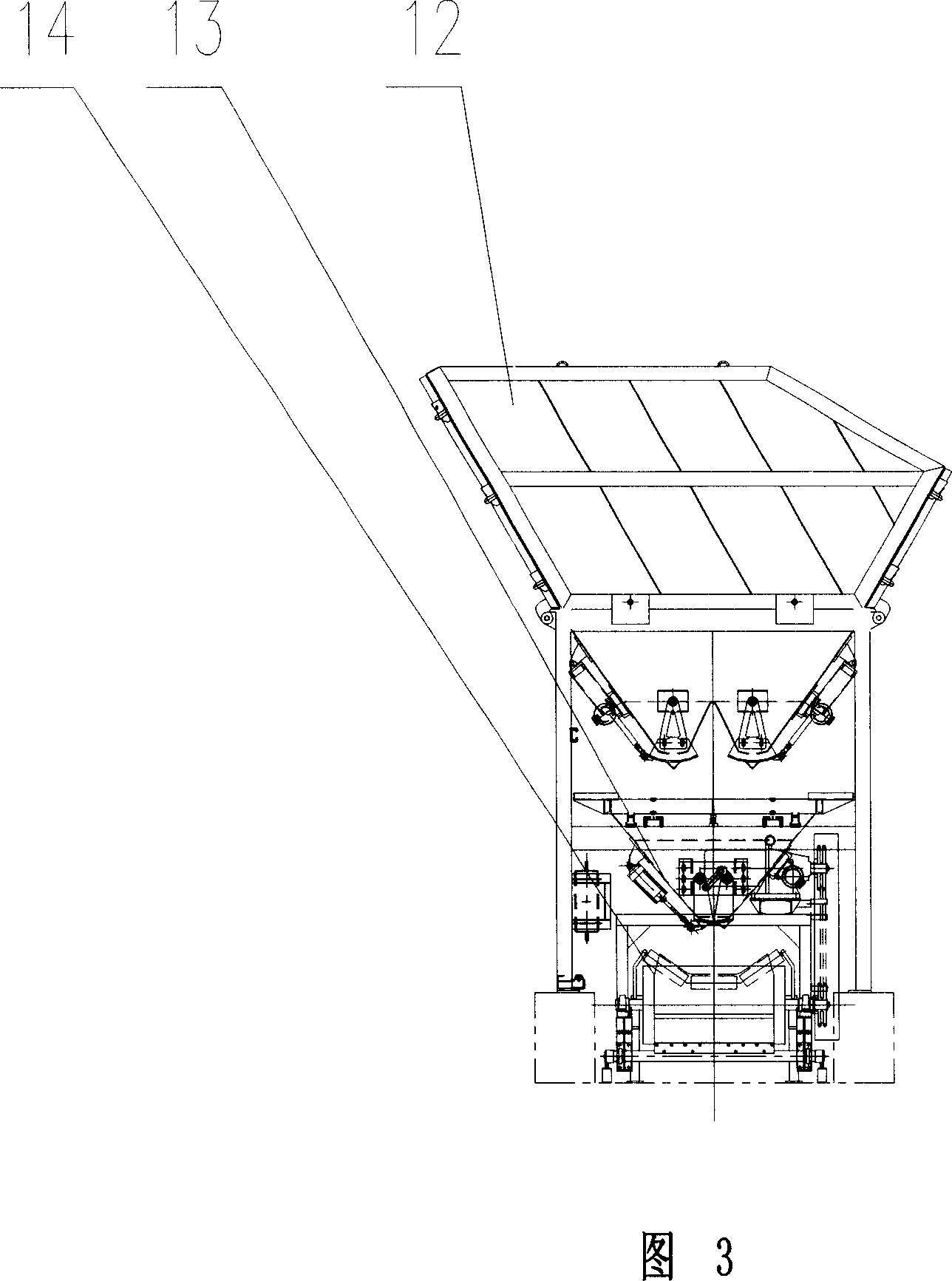

[0024] As shown in Fig. 1, Fig. 2, Fig. 3, Fig. 4 and Fig. 5, the high-performance concrete mixing plant of the present invention includes a batching machine 1, an aggregate hoist 2, a mixer 4, a powder weighing device 5, an external Additive weighing device 6, water weighing device 7 and powder bin 8, one end of the aggregate elevator 2 is located at the discharge port 15 of the batching machine 1, and the other end is located above the feed port of the mixer 4, the admixture weighing device 6. The water weighing device 7 and the powder material weighing device 5 connected to the powder bin 8 are respectively installed above the feed port of the mixer 4 . Referring to Fig. 2 and shown in Fig. 3, batching machine 1 comprises frame 11 and aggregate bin 12 fixed on frame 11, aggregate weighing device 13 and belt conveyor 14, aggregate b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com