Building block and system for manufacture

a technology of building blocks and blocks, applied in the direction of walls, solid waste management, sustainable waste treatment, etc., can solve the problem that utilizing high compression on these types of ingredients works negatively on the hardening process as the blocks, and achieves the effect of high strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

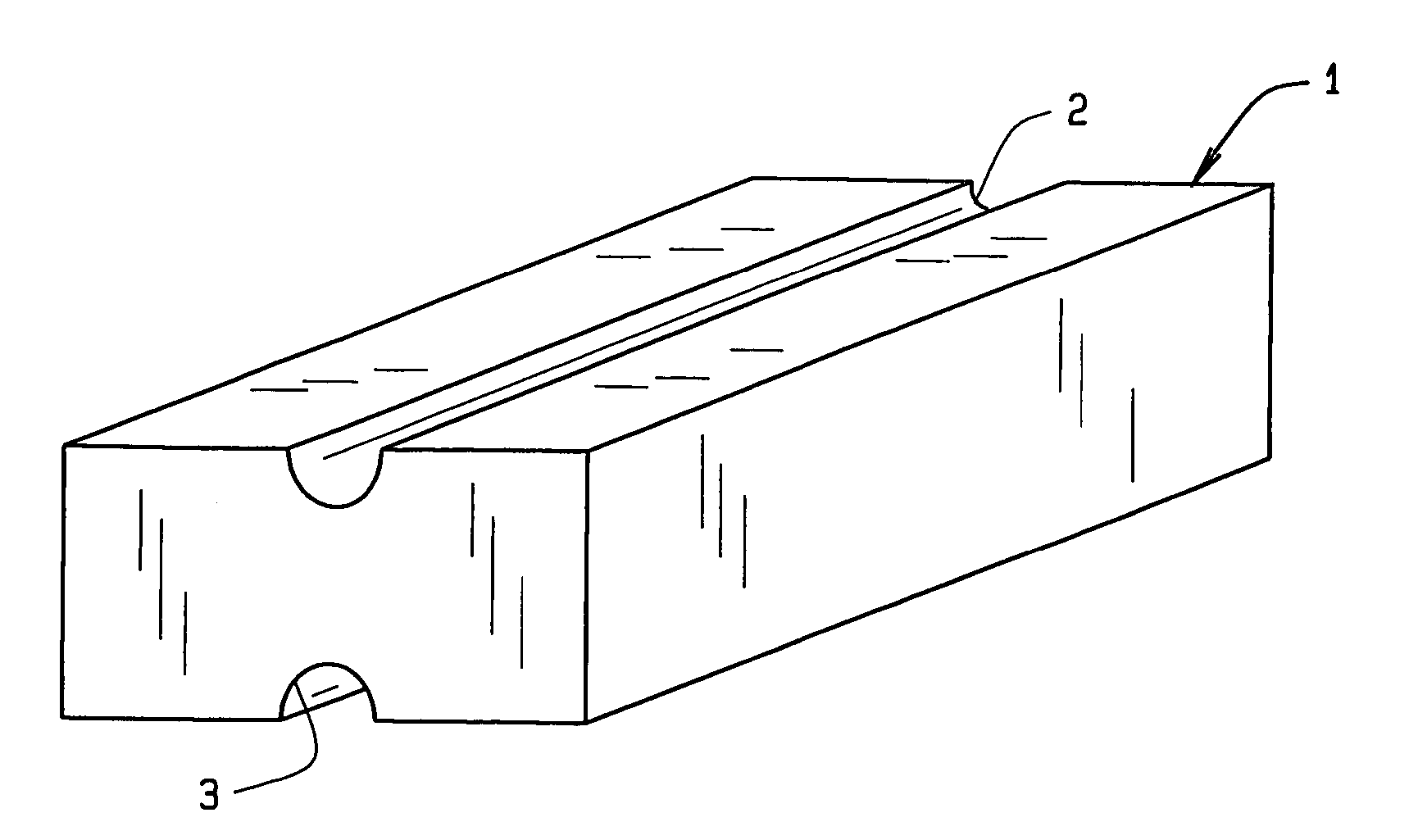

[0056] In referring to the drawings, and in particular FIG. 1, is an example of the way that the blocks can be fabricated by the system of this invention as readily disclosed. The building block 1 will be of standard shape or appearance, but can be fabricated to any size, but generally may be in the range of four inches high, eight inches wide, and twelve inches in length (4″×8″×12″). Obviously, other dimensions may be used for the block of this invention, and depending upon which system is used to fabricate the blocks, the dimensions are typically 9½″×8″×17½″. The extruded block, a block of any length, even up to many feet in length, such as sixteen (16′) as previously stated, could be developed. Or, where the block is molded by hydraulic pressure, it may have dimensions similar to those as shown in FIG. 1. In addition, the block may be molded or extruded having supplemental configurations, such as the upper and lower grooves 2 and 3, in addition to the tongue and grooves 5-8, as n...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pressure | aaaaa | aaaaa |

| pressure | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com