Proportioning material metering method, proportioning weight controller, system and concrete mixing plant

A metering method and controller technology, applied in mixing plants, control devices, mixing operation control and other directions, can solve the problem that reduced batching cannot be accurately and quickly metered, and achieve the effect of improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

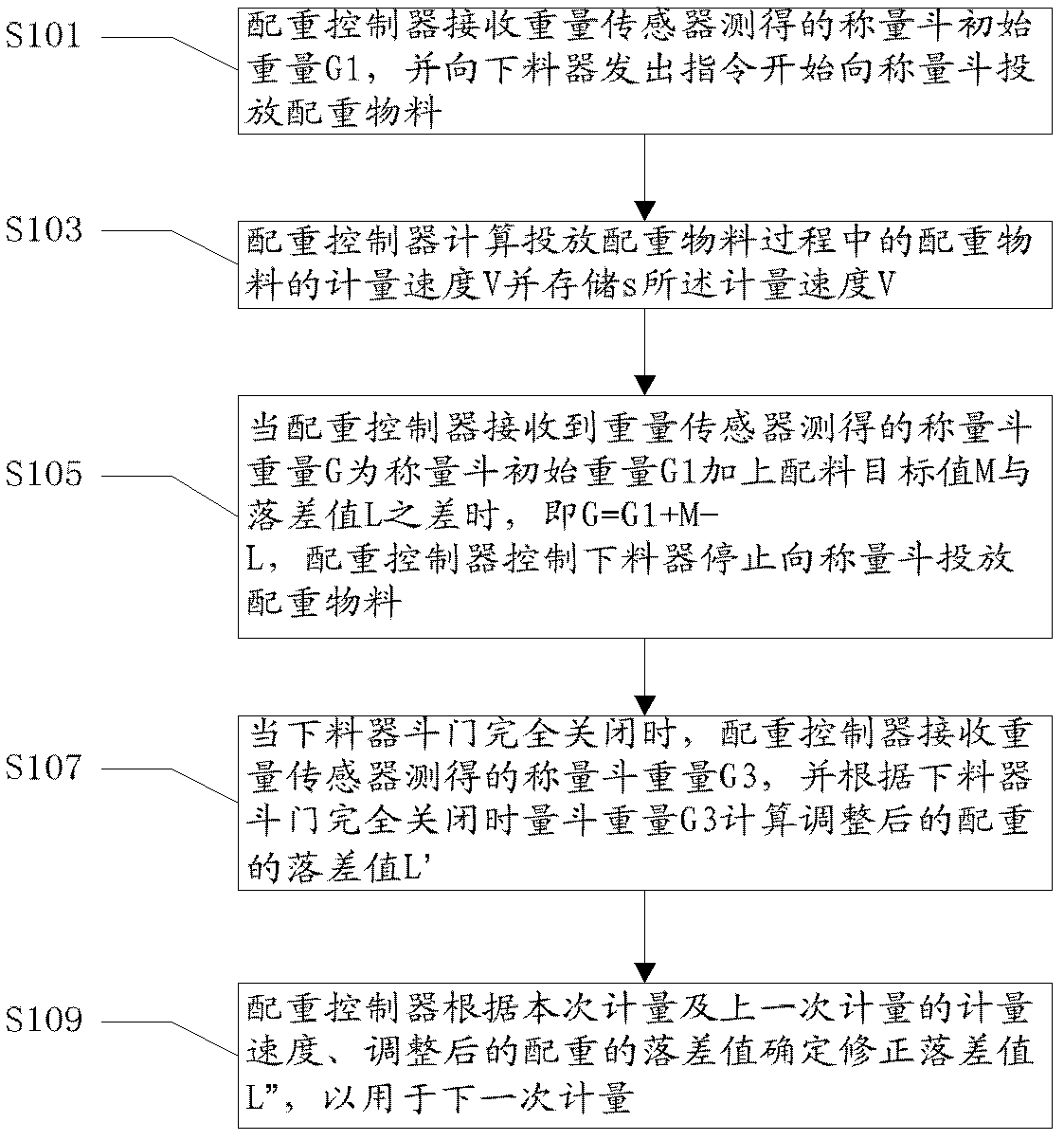

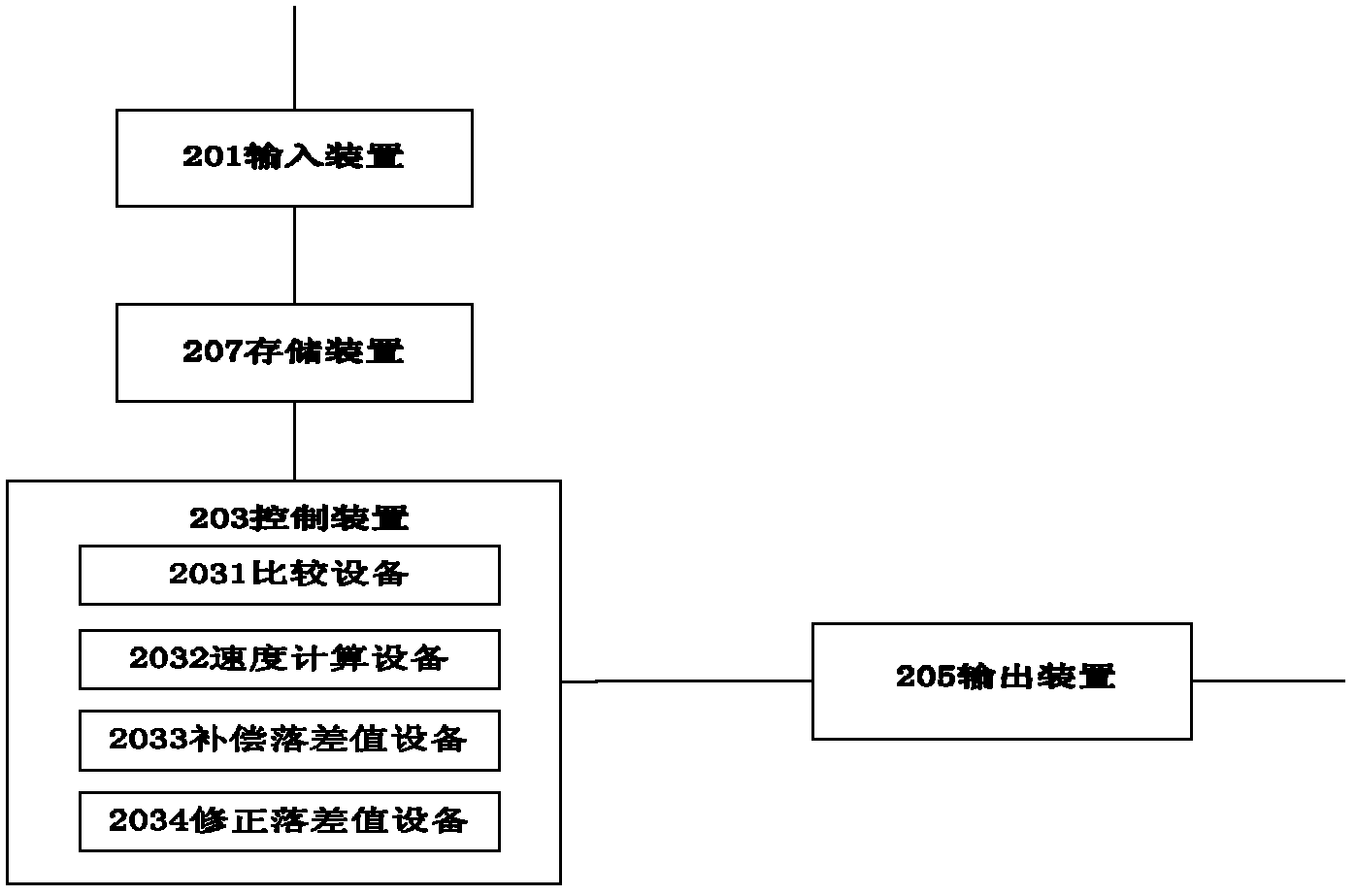

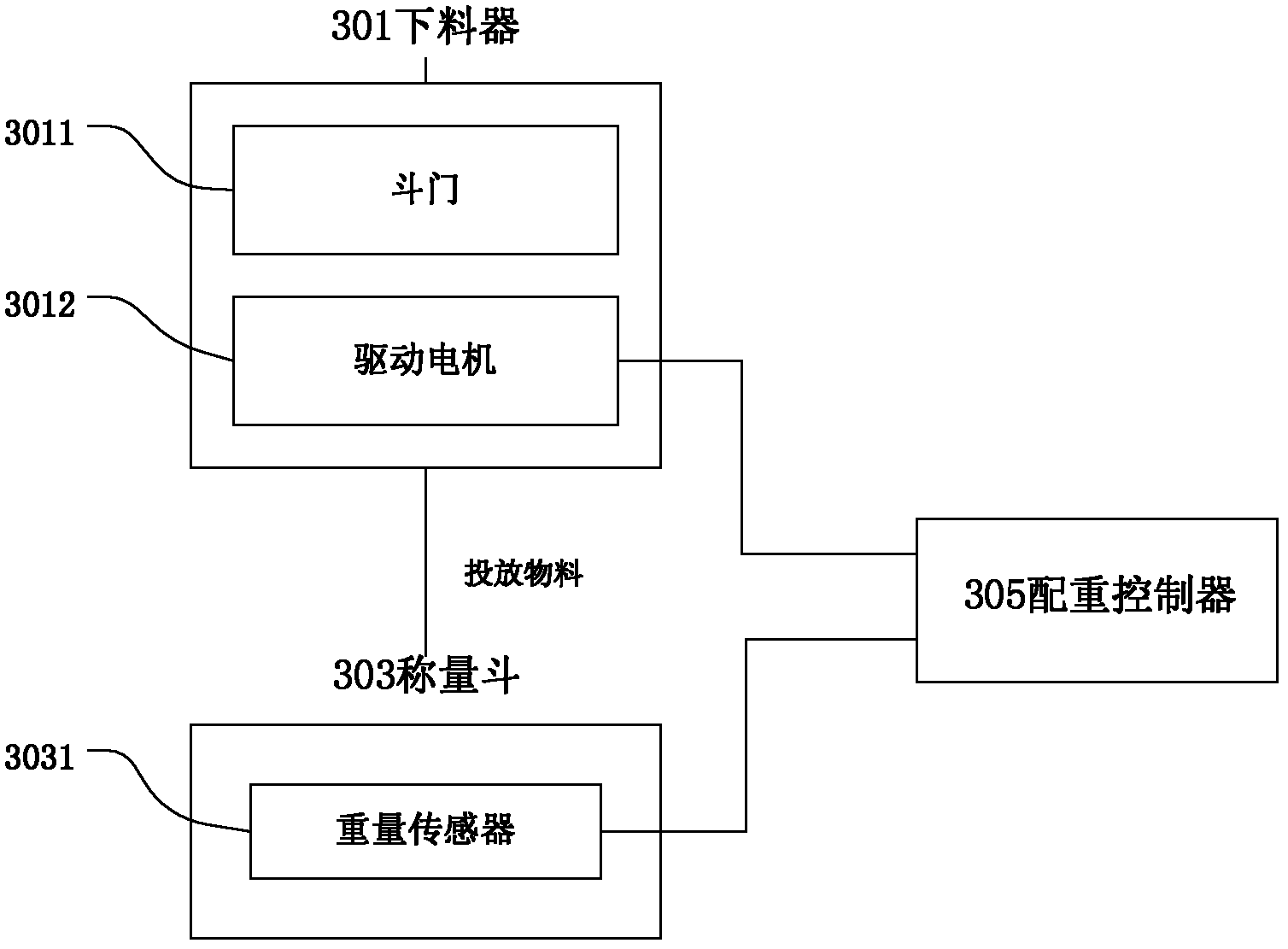

Method used

Image

Examples

Embodiment Construction

[0014] In the field of construction machinery, especially in the field of concrete measurement, in order to measure the counterweight material more accurately, the measurement of the counterweight material is not completed at one time, each time a part is measured, and the next measurement is adjusted according to the result of the previous measurement, so that the weighing The result of the measurement is close to the target value, and the inventor found in the process of realizing the present invention that the key to accurate measurement is to accurately calculate the measurement drop value. Since the time process from the beginning of closing of the bucket door of the feeder to the complete closing of the bucket door cannot be realized instantaneously, the resulting difference between the actual weighing value and the target weighing value is called the weighing drop value. In the actual measurement process, there are many factors that affect the change of the measurement d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com