Novel lightweight mullite brick and fabrication method thereof

A technology of mullite brick and sintered mullite, which is applied in the field of new lightweight mullite brick and its preparation, can solve the problems of thermal equipment steel structure deformation, large thermal conductivity, limited effect, etc., and achieve high pressure resistance Effects of strength, low thermal conductivity, and high operating temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

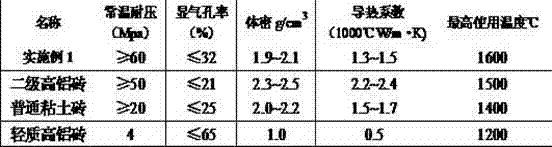

Embodiment 1

[0015] A new type of lightweight mullite brick, which is prepared from aggregate, powder and composite organic pore-forming agent plus polymer binder according to the following weight ratio and method:

[0016] Ratio: 55 parts of aggregate, including 10 parts of sintered mullite with a particle size of 0-1mm, 25 parts of sintered mullite with a particle size of 1-3mm, and the mass percentage of the chemical composition of the sintered mullite is: mullite phase 80- 90%, Fe 2 o 3 2 O+Na 2 O60%, bulk density3 , porosity > 50%; the powder is 40 parts of mixed fine powder, and the weight ratio of mixed fine powder is composed of: 35-65 parts of sintered mullite, 15-30 parts of α-alumina fine powder, 10-30 parts of silicon fine powder 15 parts, 10-15 parts of combined clay, the mass percentage of the chemical composition of α-alumina micropowder is: α-Al 2 o 3 Phase > 93%, the mass percentage of the chemical composition of silicon micropowder is: SiO 2 >99%, the mass percentage...

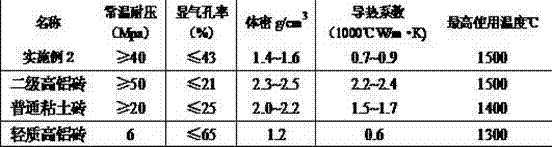

Embodiment 2

[0025] A new type of lightweight mullite brick, which is prepared from aggregate, powder and composite organic pore-forming agent plus polymer binder according to the following weight ratio and method:

[0026] Ratio: 55 parts of aggregate, including 10 parts of sintered mullite with a particle size of 0-1mm, 20 parts of sintered mullite with a particle size of 1-3mm, and the mass percentage of the chemical composition of the sintered mullite is: mullite phase 80- 90%, Fe 2 o 3 2 O+Na 2 O60%, bulk density3 , porosity > 50%; the powder material is 30 parts of mixed fine powder, and the weight ratio of mixed fine powder is composed of: 35-65 parts of sintered mullite, 15-30 parts of α-alumina micropowder, 10-30 parts of silicon micropowder 15 parts, 10-15 parts of combined clay, the mass percentage of the chemical composition of α-alumina micropowder is: α-Al 2 o 3 Phase > 93%, the mass percentage of the chemical composition of silicon micropowder is: SiO 2 >99%, the mass p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com