Cement-based composite material with high-temperature resistance and superhigh performance and preparation method thereof

An ultra-high performance, composite material technology, applied in climate sustainability, sustainable waste treatment, solid waste management, etc. The effect of bursting, saving cement clinker and avoiding collapse damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

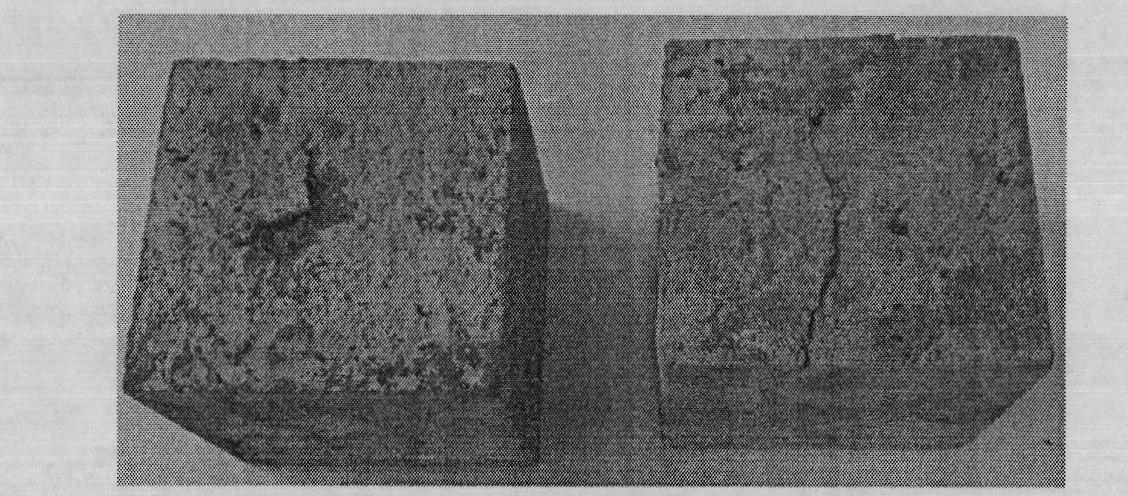

[0031] After weighing the cementitious material and aggregates according to the proportions in Table 1, dry mixing them in a concrete mixer uniformly; after weighing the fibers according to the proportions in Table 1, sprinkle them in the mixer and stir them evenly; mix the water reducing agent and water according to Table 1. After mixing evenly, pour it into the mixer and continue to stir it evenly; pour the mixture obtained after stirring evenly into a cube mold with a side length of 70.7, and vibrate it; put the molded specimen at a temperature of 20±2℃ . The relative humidity is greater than 95% in a standard curing box for 24 hours, then the mold is removed, and the specimen is cured in a standard curing box for more than 30 days. The cementitious material in Example 1 is 52.5 Portland cement, silica fume and slag micropowder with a mass ratio of 5:2:3; the aggregate is yellow sand with a particle size of less than 3 mm; the fiber is polyethylene with a length of 12 mm and...

Embodiment 2

[0034] The cement-based composite material was prepared by repeating the method of Example 1 according to the proportion of each component specified in Table 1, and then repeating the method of Example 1 to carry out the high temperature resistance test on the cement concrete specimen of this example, and the test results are listed in Table 2 . The cementitious material in Example 2 is 52.5 Portland cement, silica fume and slag micropowder with a mass ratio of 5:2:3; the aggregate is yellow sand with a particle size of less than 3 mm; the fiber is a polymer with a mass ratio of 1:12. Vinyl alcohol fiber and steel fiber, polyvinyl alcohol fiber length 12mm, diameter 39μm, steel fiber length 12mm, diameter 0.2mm, tensile strength greater than 1800MPa; water reducing agent is a polycarboxylate superplasticizer with a water reducing rate greater than 40% .

Embodiment 3

[0036] The cement-based composite material was prepared by repeating the method of Example 1 according to the proportion of each component specified in Table 1, and then repeating the method of Example 1 to carry out the high temperature resistance test on the cement concrete specimen of this example, and the test results are listed in Table 2 . The cementitious materials in Example 3 are 52.5 Portland cement, silica fume and slag micropowder with a mass ratio of 5:2:3; the aggregates are yellow sand and stones with a mass ratio of 1:1, and the particle size of the yellow sand is less than 3mm. , the stone is basalt crushed stone with a particle size of less than 16mm; the fiber is a polyvinyl alcohol fiber with a length of 12mm and a diameter of 39μm; the water reducing agent is a polycarboxylate superplasticizer with a water reducing rate greater than 40%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com