Phosphogypsum cement graded broken stone stable layer and preparation method thereof

A technology for grading crushed stone and phosphogypsum is applied in the field of phosphogypsum cement graded crushed stone stable layer, which can solve the problems of slag pollution and phosphogypsum accumulation, and achieve the effect of solving the accumulation and improving the promotion value.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] This embodiment proposes a phosphogypsum cement graded crushed stone stabilization layer, including aggregates and phosphogypsum comprehensive stabilization materials, wherein the aggregates include coarse aggregates and fine aggregates,

[0037] Coarse aggregates include crushed stones of three particle sizes, including 15 parts of crushed stones with a particle size of 4.75-9.5 mm, 25 parts of crushed stones with a particle size of 9.5-19 mm, and 30 parts of crushed stones with a particle size of 19-26.5 mm.

[0038] Fine aggregate, including 30 parts of stone chips with a particle size of 0-4.75mm;

[0039] The addition amount of phosphogypsum comprehensive stabilizing material is 15% of the aggregate; the water content of the graded gravel stabilizing layer is 7.0%.

[0040] Preferably, the phosphogypsum comprehensive stabilization material includes 15 parts of phosphogypsum, 10 parts of cement, and 10 parts of mineral powder.

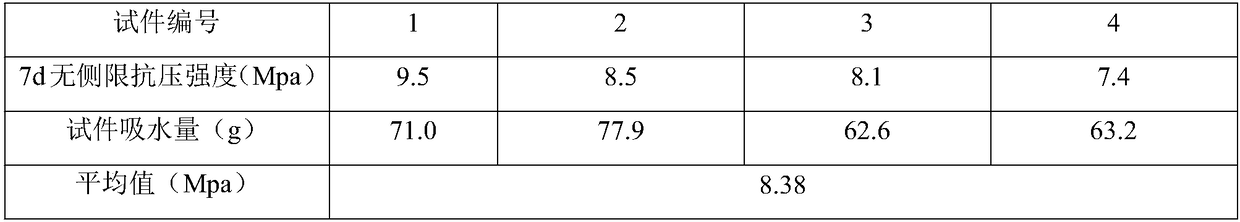

[0041] This embodiment also provides...

Embodiment 2

[0052] This embodiment proposes a phosphogypsum cement graded crushed stone stabilization layer, including aggregates and phosphogypsum comprehensive stabilization materials, wherein the aggregates include coarse aggregates and fine aggregates,

[0053] Coarse aggregates include crushed stones of three particle sizes, including 20 parts of crushed stones with a particle size of 4.75-9.5mm, 20 parts of crushed stones with a particle size of 9.5-19mm, and 25 parts of crushed stones with a particle size of 19-26.5mm.

[0054] Fine aggregate, including 35 parts of stone chips with a particle size of 0-4.75 mm;

[0055] The addition amount of phosphogypsum comprehensive stabilizing material is 18% of the aggregate; the water content of the graded gravel stabilizing layer is 7.5%.

[0056] Preferably, the phosphogypsum comprehensive stabilization material includes 18 parts of phosphogypsum, 10 parts of cement, and 10 parts of mineral powder.

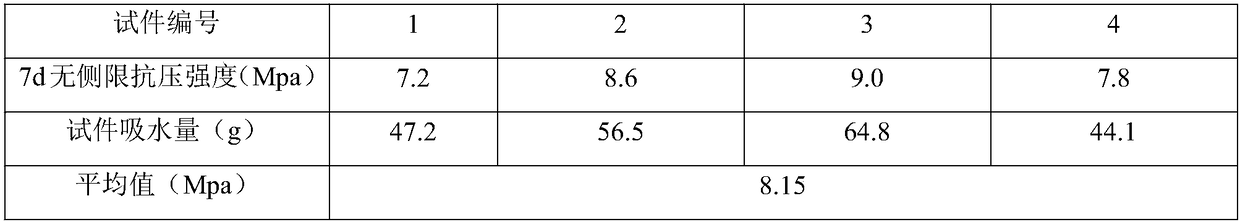

[0057] This embodiment also provides a...

Embodiment 3

[0068] This embodiment proposes a phosphogypsum cement graded crushed stone stabilization layer, including aggregates and phosphogypsum comprehensive stabilization materials, wherein the aggregates include coarse aggregates and fine aggregates,

[0069] Coarse aggregates include crushed stones of three particle sizes, including 25 parts of crushed stones with a particle size of 4.75-9.5 mm, 15 parts of crushed stones with a particle size of 9.5-19 mm, and 30 parts of crushed stones with a particle size of 19-26.5 mm.

[0070] Fine aggregate, including 40 parts of stone chips with a particle size of 0-4.75mm;

[0071] The addition amount of phosphogypsum comprehensive stabilizing material is 20% of the aggregate; the water content of the graded gravel stabilizing layer is 8.1%.

[0072] Preferably, the phosphogypsum comprehensive stabilization material includes 20 parts of phosphogypsum, 10 parts of cement, and 10 parts of mineral powder.

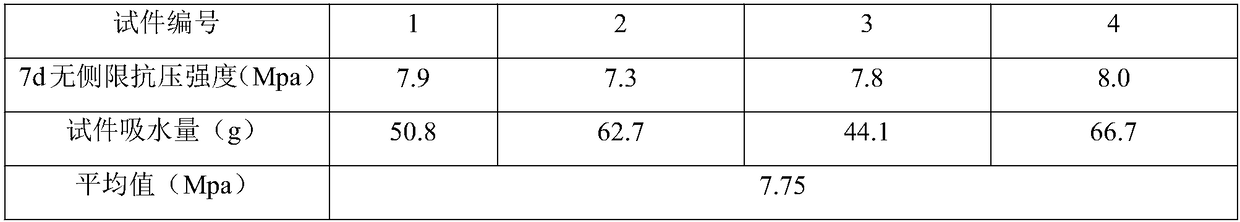

[0073] This embodiment also provides...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com