Three-phase composite conductive anti-freezing asphalt mixture and preparation method thereof

A kind of asphalt mixture, composite conductive technology, applied in the field of composite conductive phase materials, three-phase composite conductive antifreeze asphalt mixture, can solve the problems of poor mechanical properties and fatigue resistance, unstable electrical conductivity, etc., to achieve high temperature Mechanical properties, avoidance of negative effects, effects of reducing traffic jams and traffic accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Embodiment 1: Preparation of Sup-13 three-phase composite conductive asphalt mixture

[0037] 1. Material preparation:

[0038] Graphite, choose flake graphite, the density is 2.1%-2.3%g / cm 3 , particle size 0.10-0.20mm, carbon content ≥ 95%wt.

[0039] Carbon fiber, single filament diameter 0.010-0.015mm, carbon content ≥ 90%wt.

[0040] Steel slag is a multi-mineral solid solution formed by quenching the waste slag produced in converter steelmaking. The particle size range is ≤9.5mm, and FeO accounts for 24.5%wt~26%wt.

[0041] The asphalt is 70# road petroleum asphalt produced by SK Korea.

[0042] Aggregate, the stone used in this example is sieved gravel, and the aggregate is classified according to the commonly used classification requirements. The classification used in this example is: ≤3mm, 3-5mm, 5-10mm and 10-15mm .

[0043] Mineral powder, limestone processing mineral powder is required, the particle size requirement is 100% of 0.6mm sieve hole pass ...

Embodiment 2

[0055] Example 2: Preparation of SMA-13 three-phase composite conductive asphalt mixture

[0056] 1. Material preparation:

[0057] Graphite, choose flake graphite, the density is 2.1%-2.3%g / cm 3 , particle size 0.10-0.20mm, carbon content ≥ 95%wt.

[0058] Carbon fiber, single filament diameter 0.010-0.015mm, carbon content ≥ 90%wt.

[0059] Steel slag is a multi-mineral solid solution formed by quenching the waste slag produced in converter steelmaking. The particle size range is ≤13.2mm.

[0060] Asphalt, Shell 70# road petroleum asphalt.

[0061] Aggregate, the stone used in this example is sieved gravel, and the aggregate is classified according to the commonly used classification requirements. The classification used in this example is: ≤3mm, 3-5mm, 5-10mm and 10-15mm .

[0062] Mineral powder, limestone processing mineral powder is required, the particle size requirement is 100% of 0.6mm sieve hole pass rate, 0.15mm sieve hole pass rate of more than 90%, 0.075mm...

Embodiment 3

[0074] Embodiment 3: Preparation of Sup-13 conventional asphalt mixture, graphite conductive asphalt mixture, graphite / carbon fiber conductive asphalt mixture

[0075] Conventional asphalt mixture, by weight percentage, consists of:

[0076] Aggregate: 91.8%

[0077] Asphalt: 5.2%

[0078] Mineral powder: 3%

[0079] Graphite conductive asphalt composite material, by weight percentage, consists of:

[0080] Graphite: 18%

[0081] Aggregate: 73.2%

[0082] Asphalt: 5.2%

[0083] Mineral powder: 3.6%

[0084] Steel slag conductive asphalt mixture, by weight percentage, consists of:

[0085] Steel slag: 40%

[0086] Aggregate: 51.8%

[0087] Asphalt: 5.2%

[0088] Mineral powder: 3%

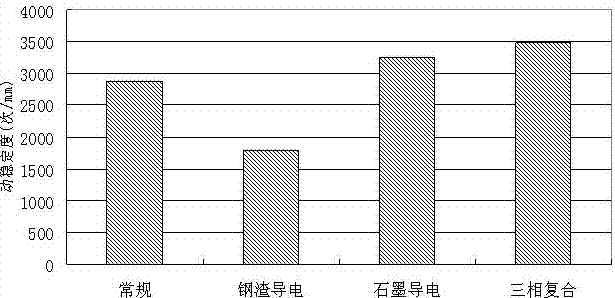

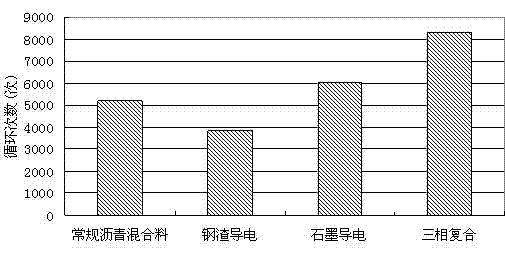

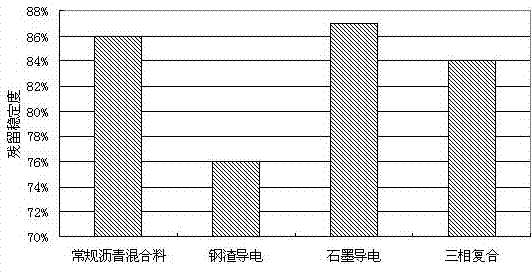

[0089] Table 1 shows the electrical conductivity ( ).

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Monofilament diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com