Connecting part of combined structure of steel and concrete and combining beam consisting of same

A technology of combining structures and connectors, which is applied in the direction of load-bearing elongated structural components, structural elements, building components, etc., can solve the problems of low construction efficiency, increase the difficulty and workload of construction, and improve construction efficiency. , Save operating time, high shearing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

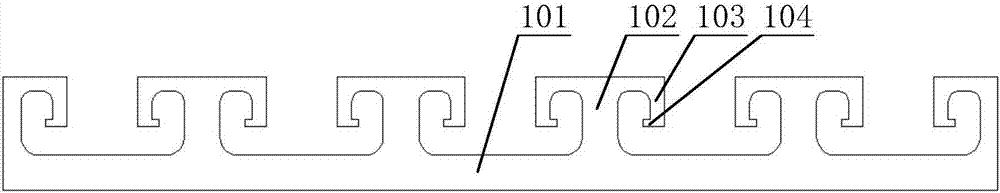

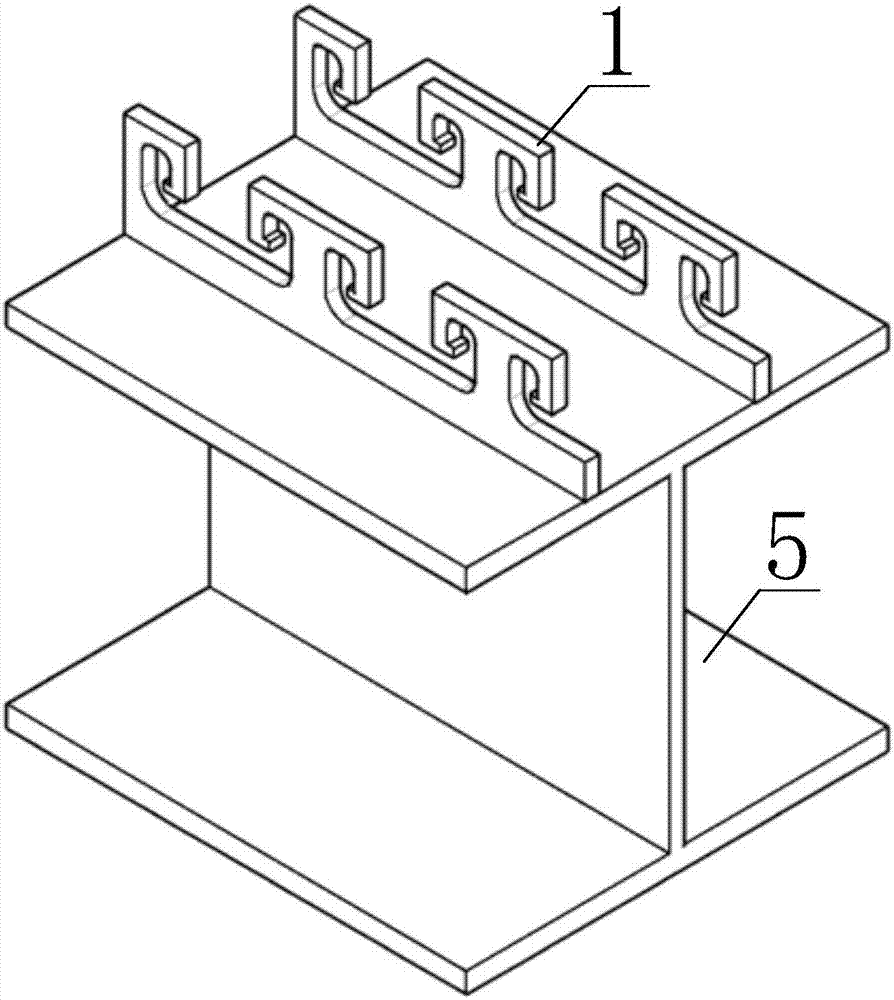

[0027] Such as figure 1 As shown, a steel and concrete composite structure connector includes a bottom plate 101 and a steel bar positioning mechanism, wherein the steel bar positioning mechanism includes a web 102, a flange plate 103 and a steel bar support block 104, and the bottom plate 101 of this embodiment is set horizontally , the web 102 is arranged vertically and its lower end is fixed on the upper surface of the bottom plate 101 , and the flange plate 103 is arranged above the bottom plate 101 and parallel to the bottom plate 101 . One end of the flange plate 103 of this embodiment is fixedly connected to the side wall of the web 102, and the bottom of the flange plate 103 is formed with a positioning gap. A rebar embedding opening is formed between the other end of the support block 104 and the side wall of the positioning notch. In this embodiment, the area between the steel bar support block 104 and the bottom plate 101 is the first steel bar rest area, and the a...

Embodiment 2

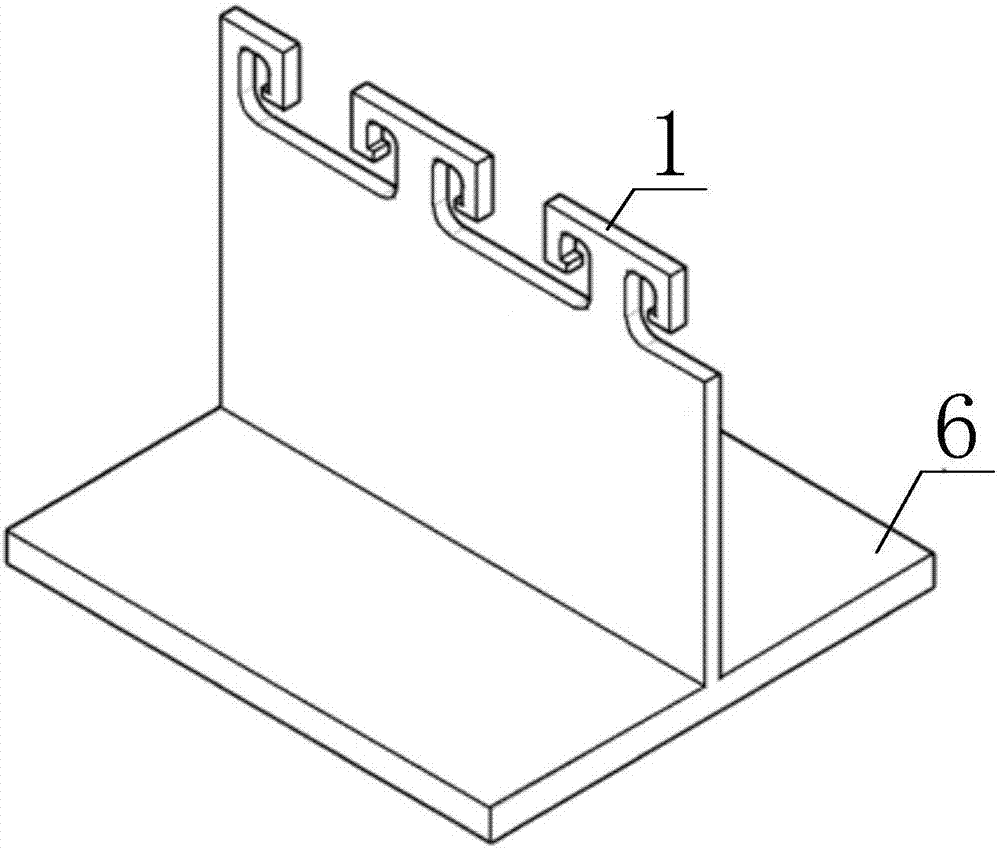

[0039] The difference between this embodiment and embodiment 1 is that this embodiment provides another kind of composite beam, the structure of the composite beam of this embodiment is as follows: this embodiment also includes T-shaped steel beam 6, upper horizontal reinforcement 2, lower horizontal reinforcement 3 and the concrete slab 4, wherein the connecting piece 1 is fixed on the T-shaped steel web of the T-shaped steel beam 6, the upper layer of transverse reinforcement 2 passes through the second steel bar resting area of the connecting piece 1 and is supported by a steel bar support block 104, and the lower layer The transverse reinforcement 3 passes through the first reinforcement rest area of the connector 1 and is supported by the bottom plate 101 ; the concrete slab 4 wraps the connector 1 , the upper transverse reinforcement 2 and the lower transverse reinforcement 3 . When this embodiment is specifically set up, the number of T-shaped steel beams 6 is more t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com