Novel short segment steel box-concrete combined beam

A technology of reinforced concrete and composite beams, applied in bridges, buildings, etc., can solve the problems of prolonging the line outage time, and achieve the effects of fast construction progress, cost reduction and short construction period.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] A realization method of a short-segment steel box-concrete composite beam using the pretensioning method:

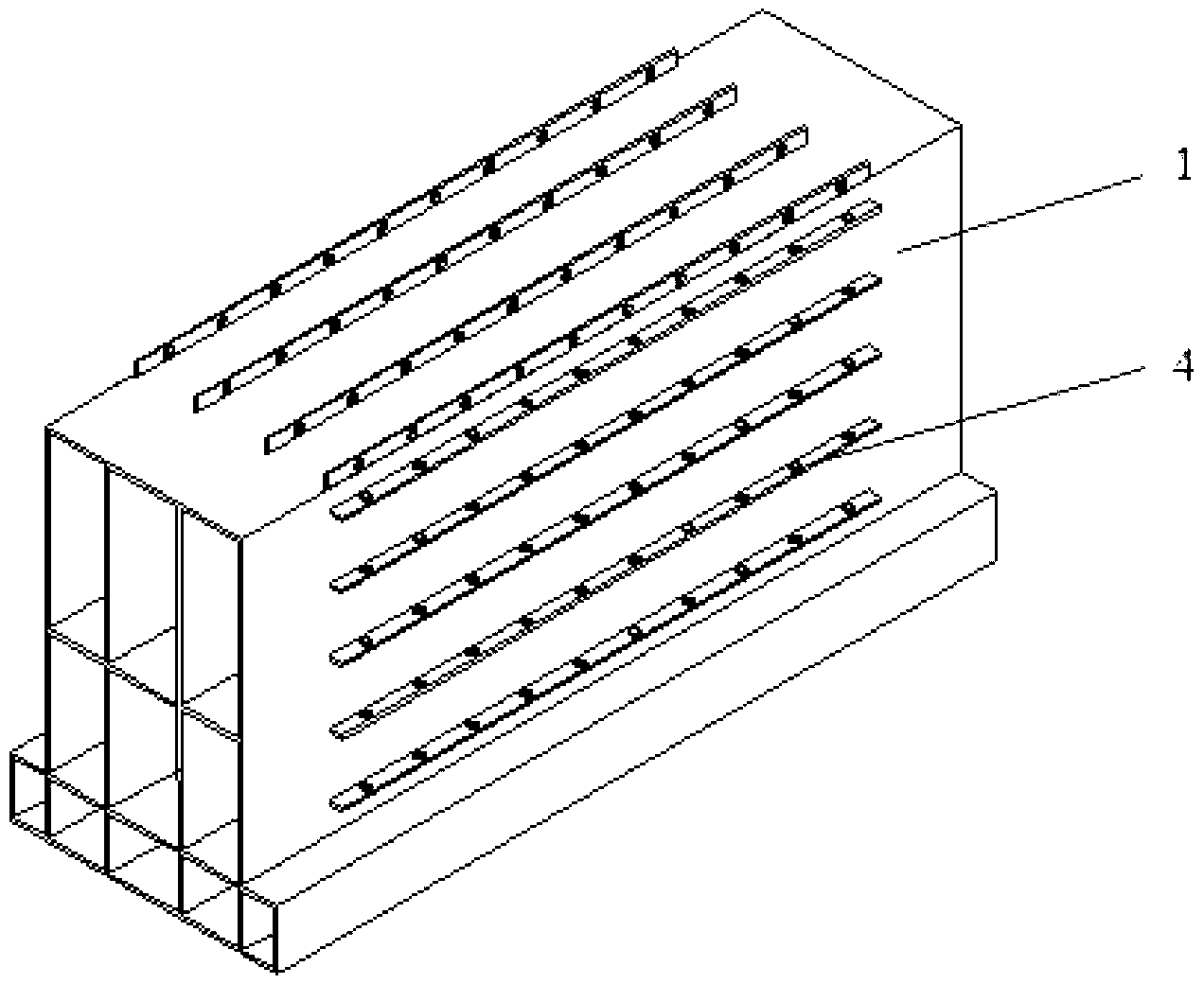

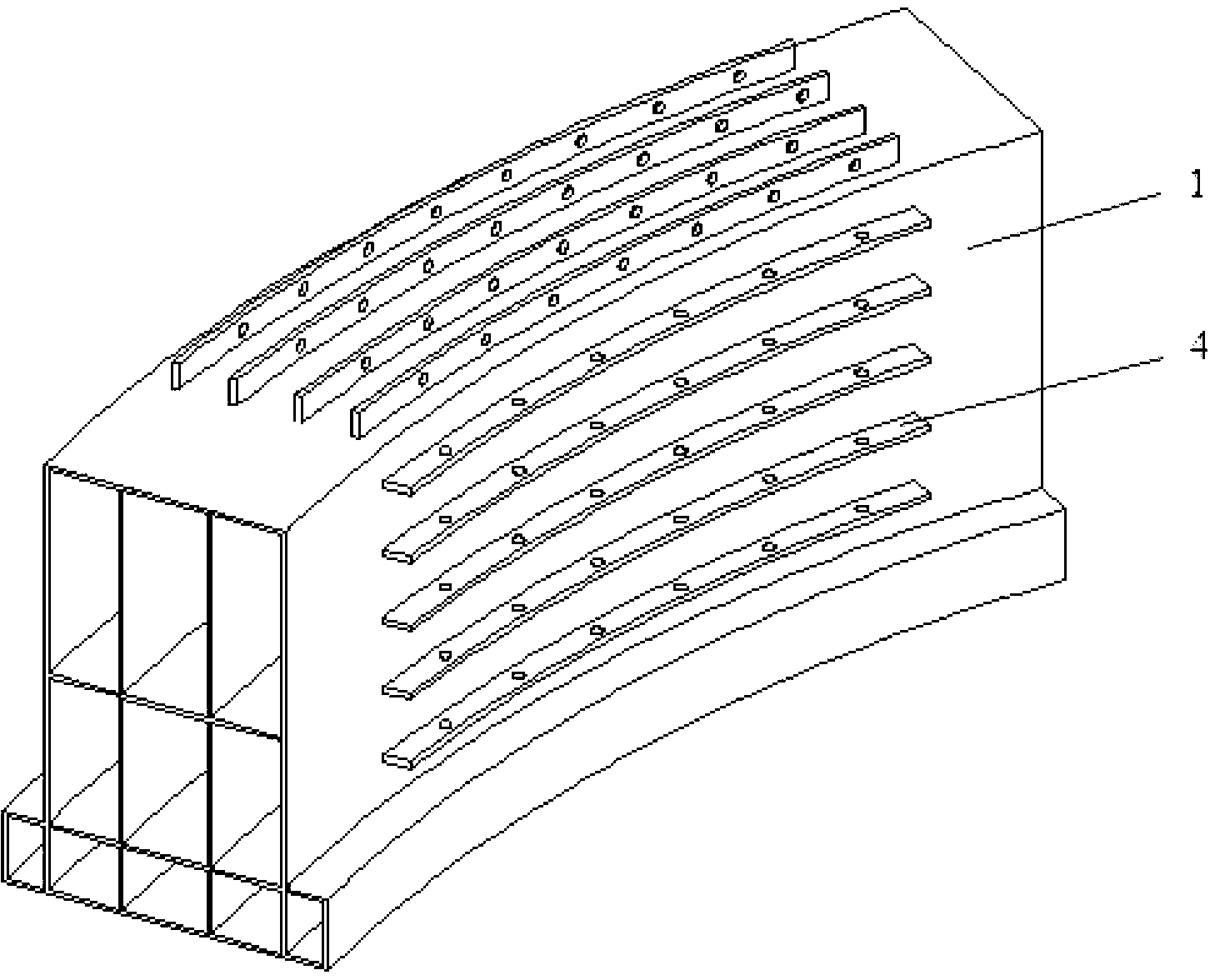

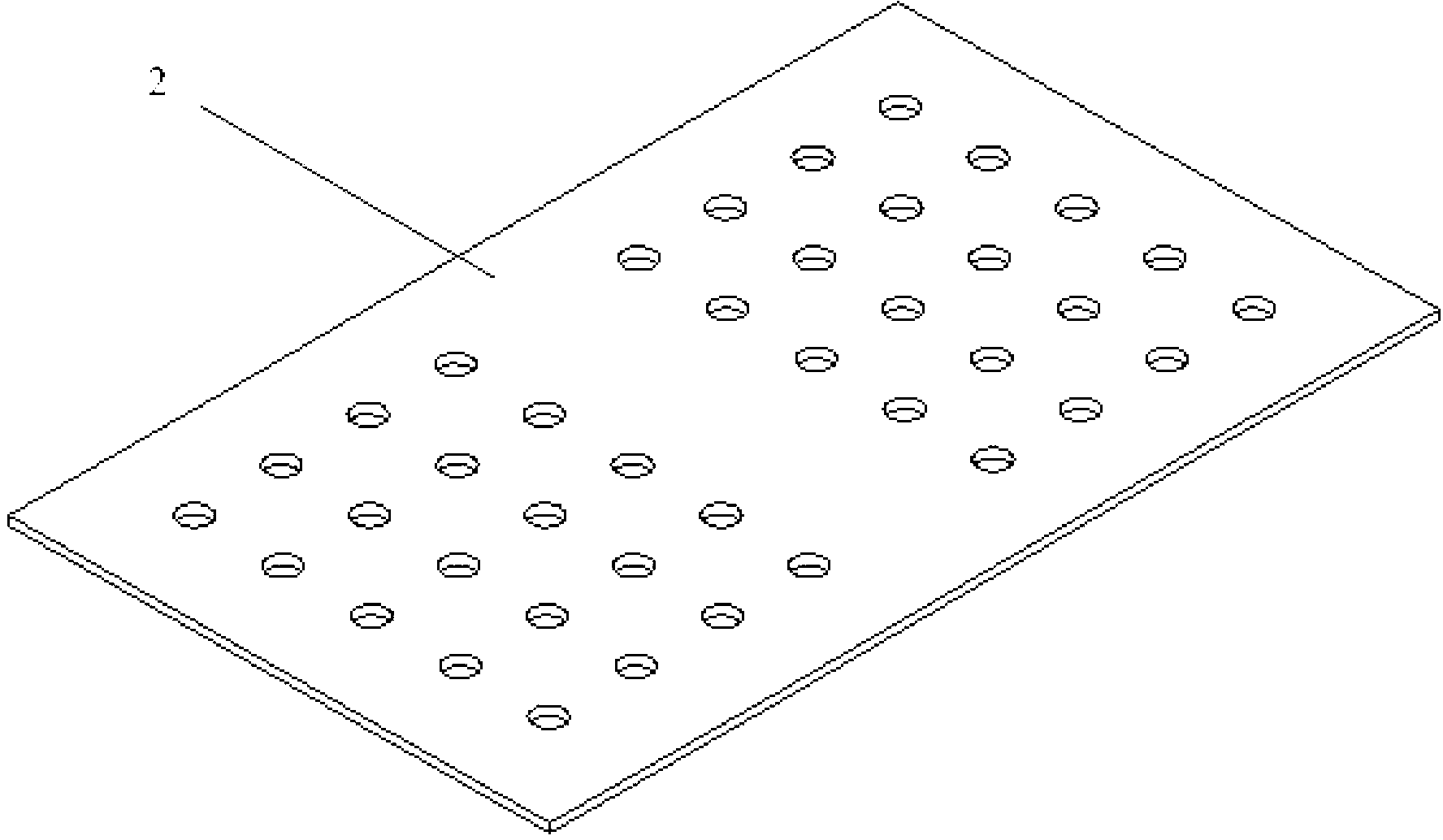

[0042] Step 1 Select the short-segment steel box (1) and the splice plate (2) according to the length, height, curve radius, plane turning angle, and wheel-rail contact surface alignment of the track beam to be replaced, such as Figure 1~Figure 5 shown.

[0043] Short segment steel boxes (1) have different lengths, heights and curve radii; splice plates (2) have different curve radii.

[0044] The value range of the length of the short segment steel box (1) is 0.5m~60m, the value range of the height is 0.5m~2.0m, the value range of the segment curve radius is 50m~∞m, the value range of the segment number The value range is 1~60; the value range of the curve radius of the splicing plate (2) is 50m~∞m, and the value range of the gap length of the gap part is 0m~0.20m; the thickness of the cast-in-place concrete (3) is selected The value range is 0.01m~0.85m; the ...

Embodiment 2

[0050] A realization method of short-segment steel box-concrete composite beam using post-tensioning method:

[0051] Step 1 Select the short-segment steel box (1) and the splice plate (2) according to the length, height, curve radius, plane turning angle, and wheel-rail contact surface alignment of the track beam to be replaced, such as Figure 1~Figure 5 shown.

[0052] Short segment steel boxes (1) have different lengths, heights and curve radii; splice plates (2) have different curve radii.

[0053] The value range of the length of the short segment steel box (1) is 0.5m~60m, the value range of the height is 0.5m~2.0m, the value range of the segment curve radius is 50m~∞m, the value range of the segment number The value range is 1~60; the value range of the curve radius of the splicing plate (2) is 50m~∞m, and the value range of the gap length of the gap part is 0m~0.20m; the thickness of the cast-in-place concrete (3) is selected The value range is 0.01m~0.85m; the valu...

Embodiment 3

[0059] A realization method of short-segment steel box-concrete composite beam without prestressing:

[0060] Step 1 Select the short-segment steel box (1) and the splice plate (2) according to the length, height, curve radius, plane turning angle, and wheel-rail contact surface alignment of the track beam to be replaced, such as Figure 1~Figure 5 shown.

[0061] Short segment steel boxes (1) have different lengths, heights and curve radii; splice plates (2) have different curve radii.

[0062] The value range of the length of the short segment steel box (1) is 0.5m~60m, the value range of the height is 0.5m~2.0m, the value range of the segment curve radius is 50m~∞m, the value range of the segment number The value range is 1~60; the value range of the curve radius of the splicing plate (2) is 50m~∞m, and the value range of the gap length of the gap part is 0m~0.20m; the thickness of the cast-in-place concrete (3) is selected The value range is 0.01m~0.85m; the value range ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com