Lightweight composite column, lightweight composite beam and load bearing lightweight composite thermal-insulation wall body

A composite wall and composite column technology, applied in the direction of heat preservation, walls, columns, etc., to achieve the effect of light weight, convenient prefabrication and installation, and good heat preservation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

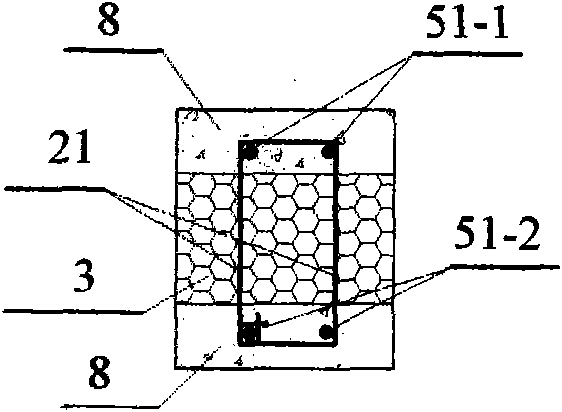

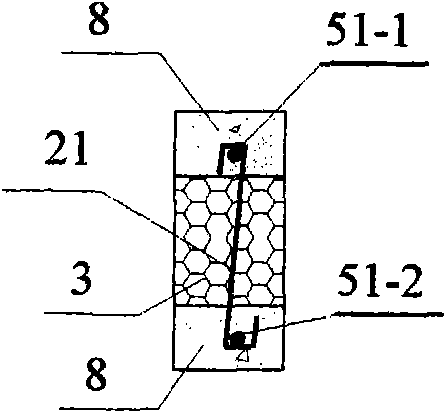

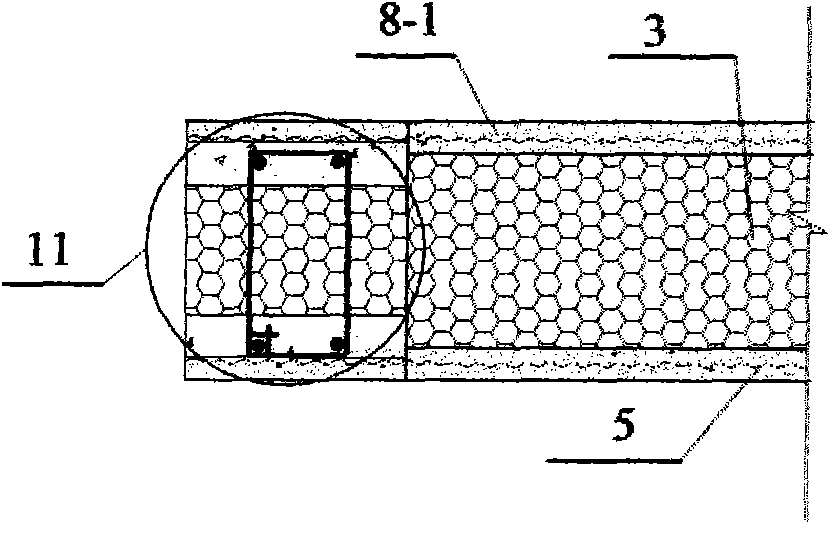

[0037] Specific implementation mode one: see figure 1 , figure 2 , a light composite column in this embodiment is composed of indoor longitudinal reinforcement 51-1, outdoor longitudinal reinforcement 51-2, steel hoop 21, core layer 3, and protective layer 8; the indoor longitudinal reinforcement 51-1, outdoor longitudinal reinforcement 51-2 are respectively located in the indoor and outdoor protective layers 8, the core layer 3 is located in the middle of the indoor and outdoor protective layers 8, the core layer 3 is bonded to the protective layers 8 on both sides; the steel hoop 21 is connected to the indoor longitudinal The steel bars 51-1 and the outdoor longitudinal steel bars 51-2 are connected and fixed to form a light-weight composite column with thermal insulation and broken bridges; the core layer 3 is a polymer insulation board, or a mineral wool board or a plant straw board or a paper honeycomb board or Perlite mortar, the protective layer 8 is cement mortar or ...

specific Embodiment approach 2

[0042] Specific implementation mode two: see Figure 5 , Figure 6 The difference between this embodiment and the first embodiment is that the protective layer 8 is located on three sides of the core layer 3 (see Figure 5 ), or the protective layer 8 is positioned around the core layer 3 and wraps the core layer 3 (see Figure 6 ), forming a light composite column with thermal bridges with protective layers on three or four sides.

[0043] If it is troublesome to prefabricate the light composite column with heat bridge, you can prefabricate the light composite column with thermal insulation bridge first, and then plaster the exposed core layer for protection after installation. Lightweight composite columns with thermal bridges can be used in non-heating areas, and can also be used for columns with low bearing capacity, such as balcony outer corner columns, decorative columns, etc.

specific Embodiment approach 3

[0044] Specific implementation mode three: see Figure 8 , the difference between this embodiment and specific embodiment 1 or 2 is that this embodiment uses alkali-resistant mesh cloth 5-1 instead of steel hoop 2; alkali-resistant mesh cloth 5-1 is pasted on the outside of protective layer 8, and the protective layer is wound and bound 8, and the core layer 3 and the indoor longitudinal reinforcement 1-1 and the outdoor longitudinal reinforcement 1-2 in the winding and bundling protective layer 8.

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com