Main girder of steel box composite girder with long cantilever arms for single-plane cable stayed bridge

A technology for steel box girder and cable-stayed bridge, applied in cable-stayed bridges, bridges, bridge parts, etc., can solve the problems of reducing the amount of on-site work, limiting the size of the external section, reducing the lateral size of the main girder, and reducing on-site work. Quantity, erection period guarantee, the effect of reducing the horizontal size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The specific embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings.

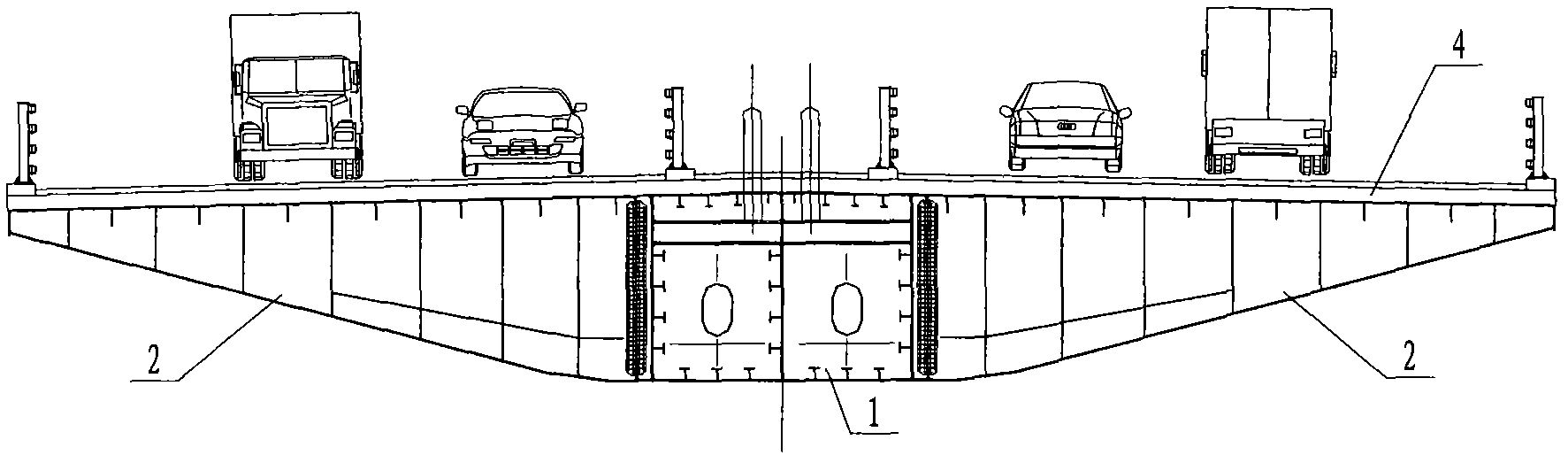

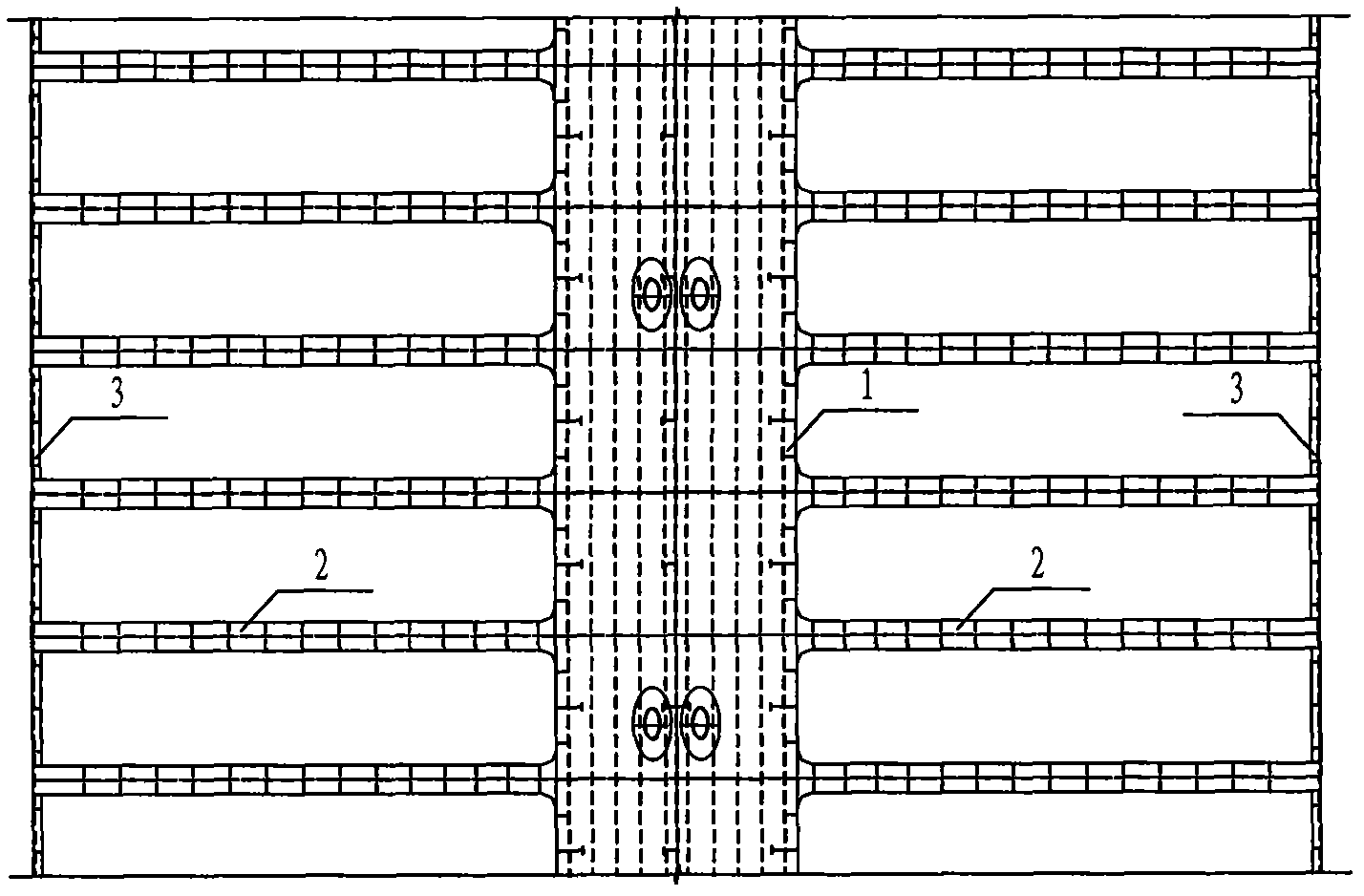

[0019] refer to figure 1 , figure 2 The two sides of the steel box girder in the middle of the main girder are steel cantilever arms, and the end of the steel cantilever arm is a side longitudinal beam. The top of the steel box girder and steel cantilever arm is laid with a concrete bridge deck or a cast-in-place bridge deck, and the roadway is located on the steel cantilever arm.

[0020] The prefabricated concrete bridge deck is set on the steel cantilever, and then the concrete is poured on site, and the steel box girder and the steel cantilever are reliably combined with the concrete slab through the shear nails welded on the top plate of the steel box girder and the steel cantilever top.

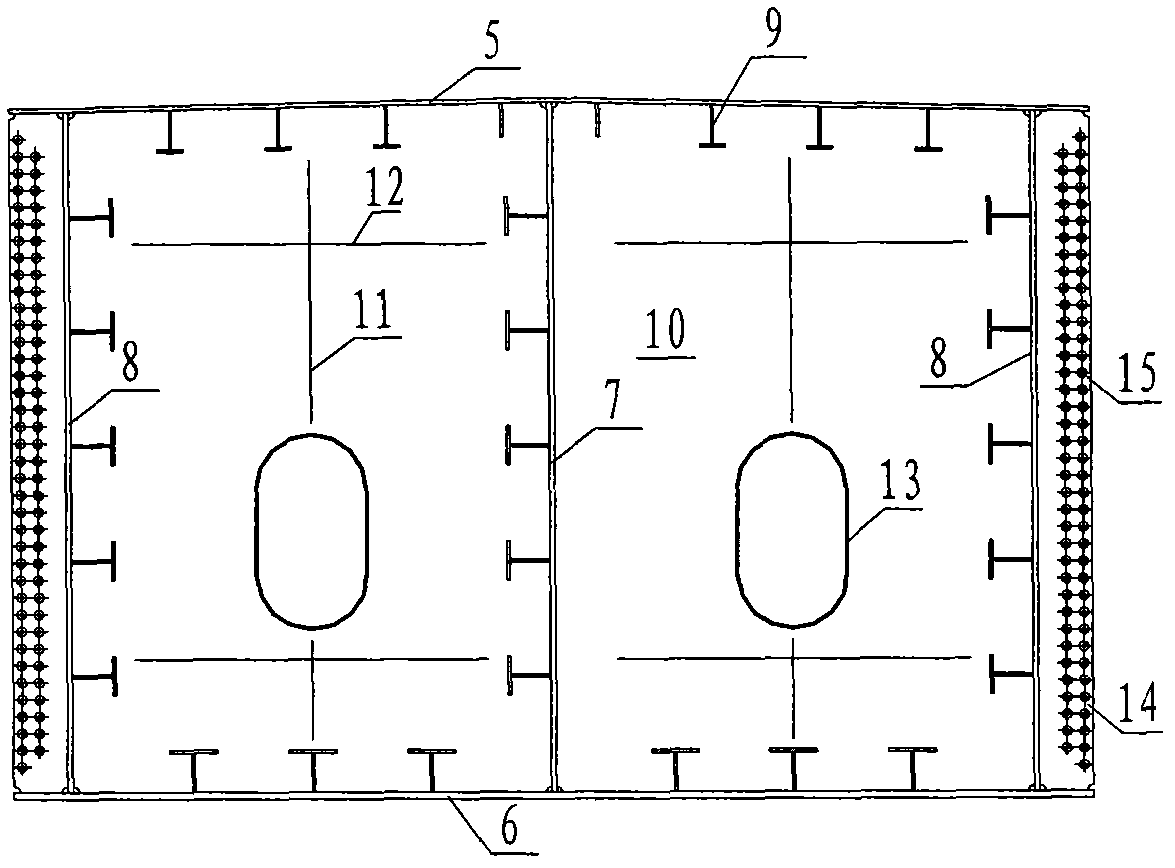

[0021] refer to image 3 , steel box girder top plate 5, steel box girder bottom plate 6, side web 7 and middle web 8 in the middle of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com