Bridge deck and steel girder second combination method for whole arch precasted steel-concrete composite continuous box girder

A secondary combination, bridge deck technology, applied in the direction of bridges, bridge construction, erection/assembly of bridges, etc., can solve the problems of high difficulty and high construction requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Steel-concrete composite structure continuous box girder prefabrication field prefabrication realizes the first combination and after floating erection, the pier top is simply supported and continuously completes the second combination construction description:

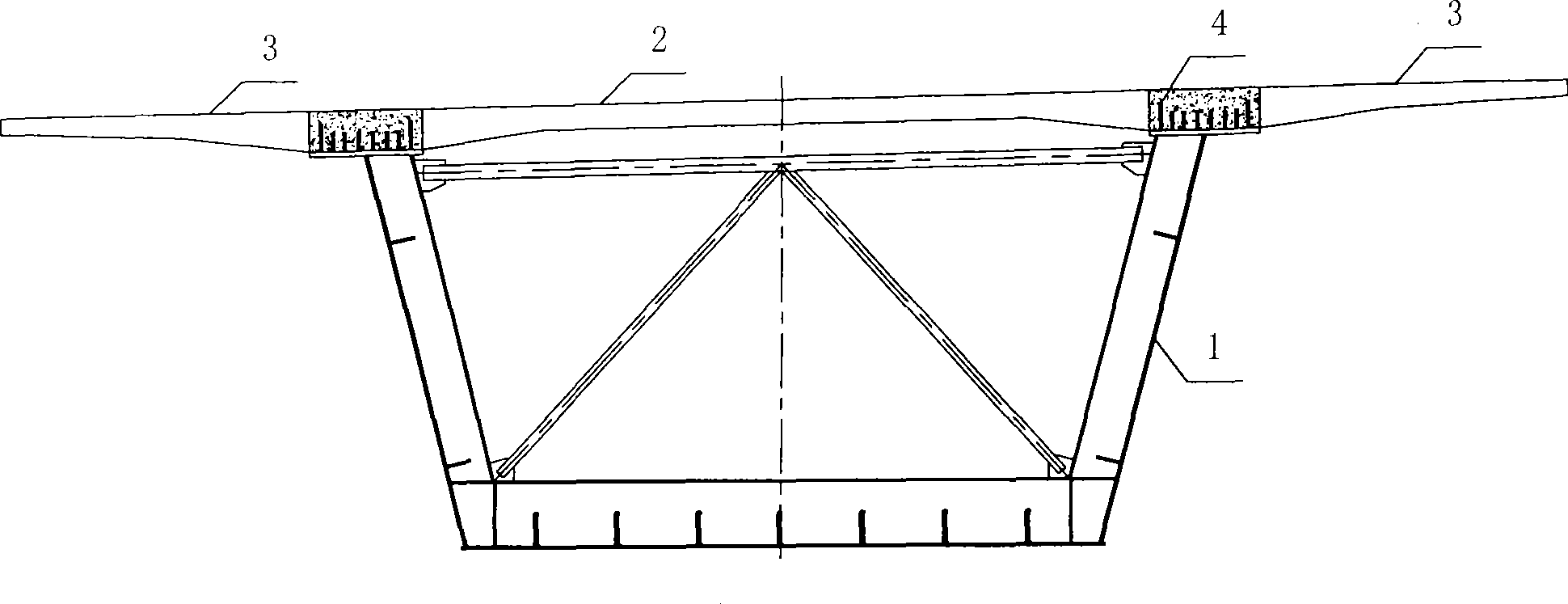

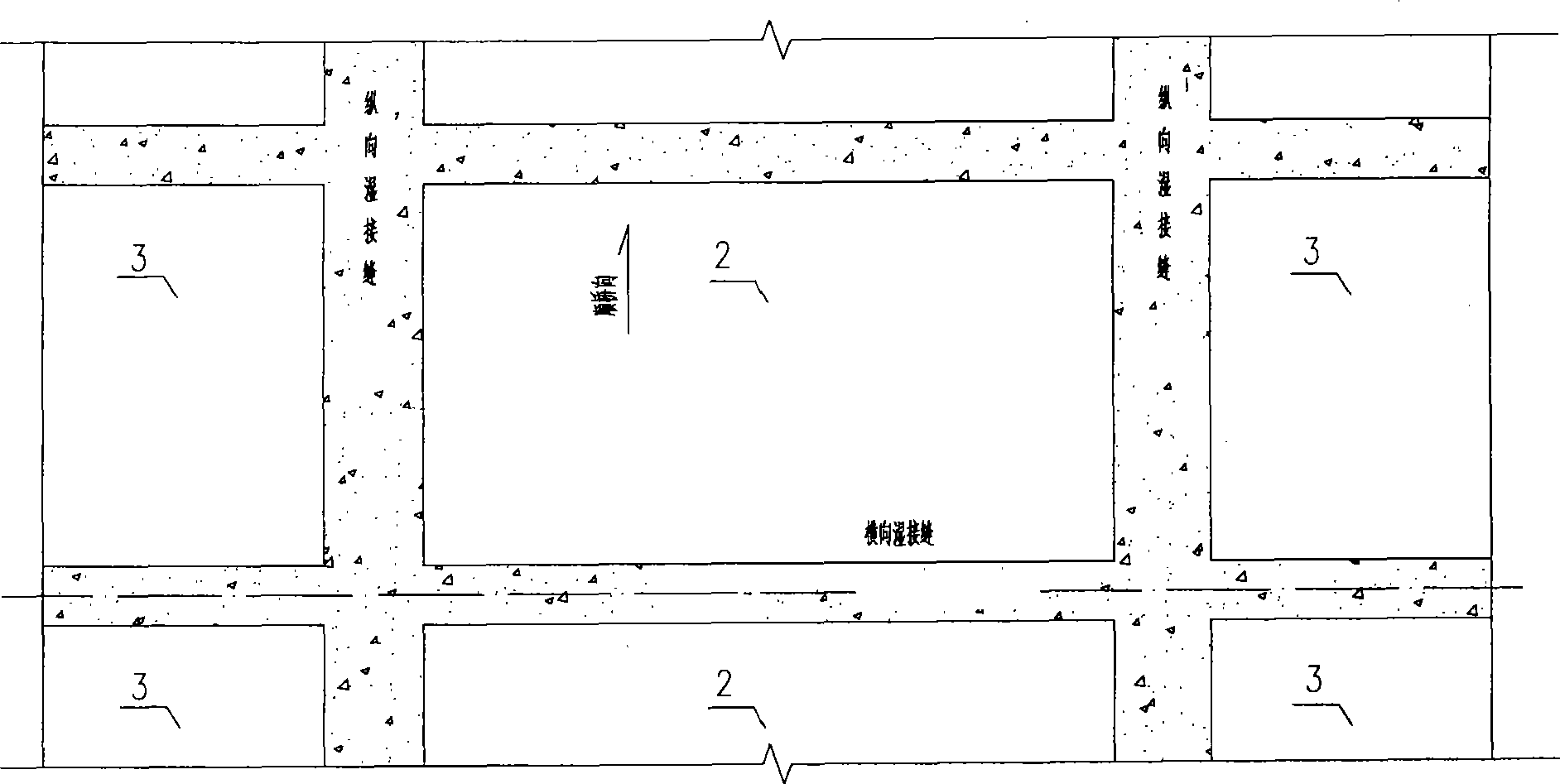

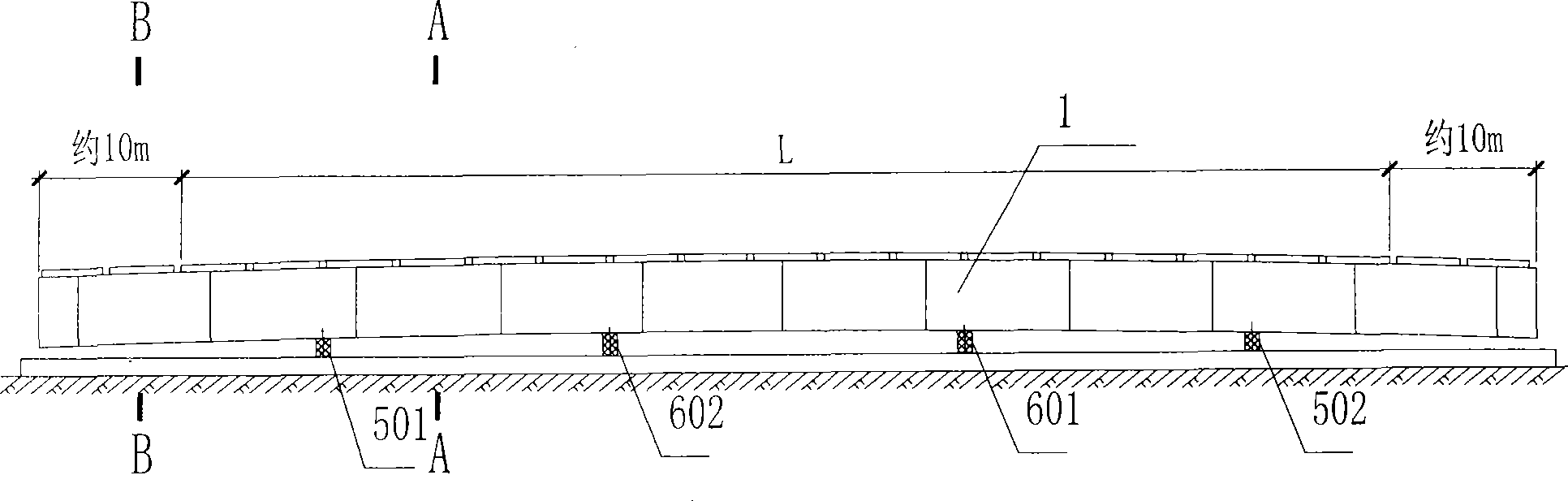

[0029] The span of the continuous box girder of the long-span steel-concrete composite structure of the Shanghai Yangtze River Tunnel Bridge is (85+5×105+90) m. figure 1 , 2 As shown, the cross-section of the composite girder bridge deck is formed by pouring longitudinal wet joint concrete on the top plate welded with shear studs 4 by a prefabricated middle plate 2 and two side plates 3 . Joint pouring connects each bridge deck into a whole. The composite beam is prefabricated by the whole beam field, and the world advanced construction technology of large-scale crane ship is transported and erected at sea. The composite beam is in the prefabrication field, and the steel beam assembly frame and the steel-concr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com