Bridge deck slab longitudinal unequal strength steel-concrete composite structure bridge and construction method thereof

A composite structure and bridge deck technology, applied to bridges, bridge parts, bridge materials, etc., can solve problems such as high cracking risk and reduced stiffness, improve long-term service performance and durability, increase strength and stiffness, and reduce steel consumption volume effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

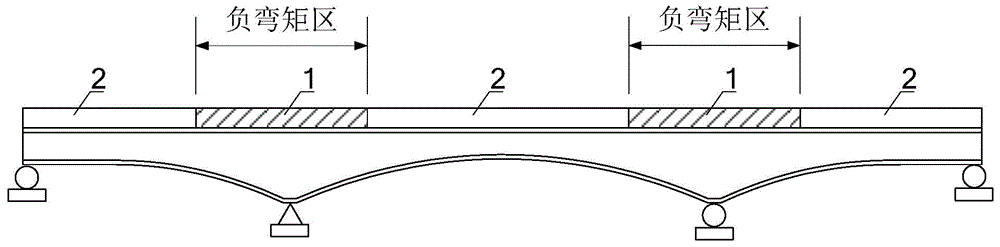

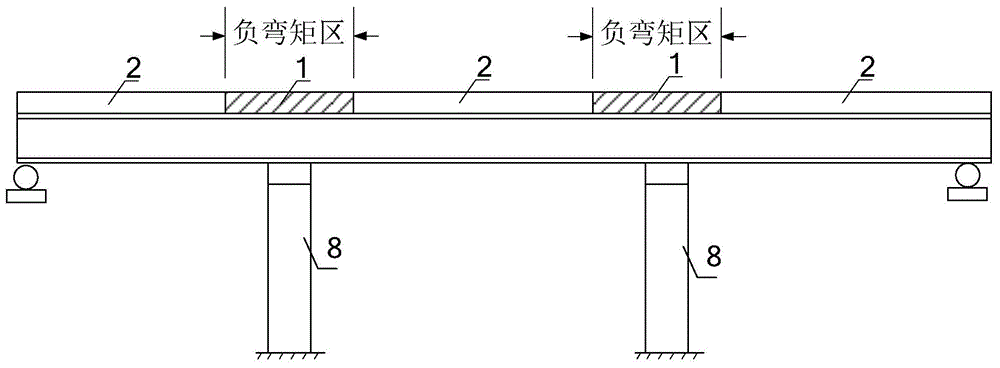

[0025] The bridge deck longitudinal unequal strength composite structure bridge provided by the present invention comprises ultra-high performance concrete 1, ordinary concrete 2 and steel girder (by upper flange 3, web 4 and base plate 5), such as figure 1 with figure 2 shown.

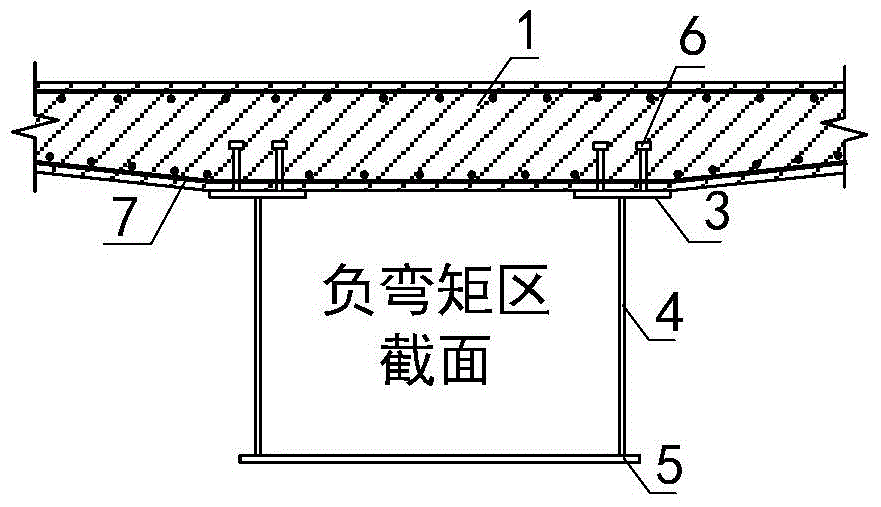

[0026] In order to ensure the combined effect of the steel beam and the concrete slab, a connector with shear and pull resistance can be welded above the upper flange 3 of the steel beam, and the connector can use studs 6, such as image 3 shown.

[0027] According to engineering needs, a certain number of stressed steel bars and structural steel bars 7 can be arranged in ultra-high performance concrete 1 and ordinary concrete 2, such as image 3 with Figure 4 As shown, a certain number of steel fibers (not shown in the figure) are arranged in the ultra-high p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com