Partial filling type steel box concrete continuous composite girder bridge and construction method thereof

A technology of steel box concrete, construction methods, applied in bridges, bridge construction, erection/assembly of bridges, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Embodiments of the invention are described in detail below, but the invention can be practiced in many different ways as defined and covered by the claims.

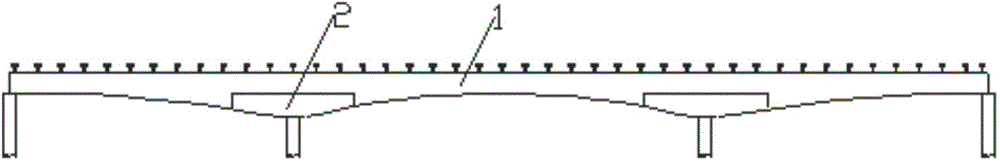

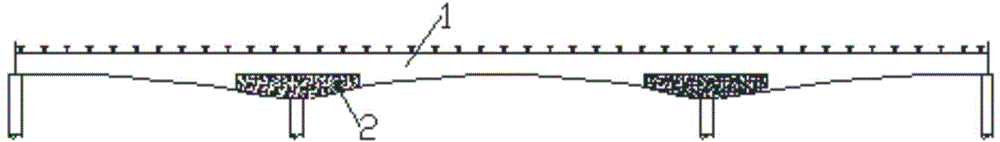

[0019] Please refer to Figure 1 to Figure 4 , the invention provides a construction method of a partially filled steel box concrete continuous composite girder bridge, comprising: Step 1, erecting a steel box continuous beam 1; Step 2, pouring concrete in the middle support area 2; Step 3, The first reinforced concrete bridge deck 5 is poured in the mid-span area 3; step 4, the second reinforced concrete bridge deck 6 is poured in the middle support area 4.

[0020] Through the above method, the present invention constructs the bridge deck in sections, the purpose of which is to improve the crack resistance of the reinforced concrete bridge deck in the mid-span section. The tensile stress is generated in the bridge deck in the middle bearing area after pouring, and the crack resistance of the reinforced concrete ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com