Steel-concrete combined beam wet joint corrosion prevention construction method and application

A construction method and concrete technology, applied in the direction of bridges, bridge parts, bridge construction, etc., can solve the problems of no anti-corrosion significance, can not achieve the design effect, etc., and achieve the effect of preventing the intrusion of corrosive media, compacting the contact surface, and preventing the entry of corrosive media.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

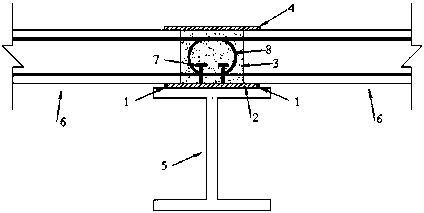

[0027] Such as figure 1 As shown, a steel-concrete composite beam wet joint anti-corrosion construction method of the present invention includes steel-concrete contact interface anti-corrosion, wet joint anti-corrosion concrete and wet joint top surface anti-corrosion.

[0028] The anti-corrosion part of the steel-concrete contact interface includes pasting a high-elastic-modulus anti-corrosion chlorinated rubber strip 1 and a high-strength and fast-curing epoxy mortar 2 for construction.

[0029] The method steps are:

[0030] a) Firstly, the high elastic modulus anticorrosion chlorinated rubber strip 1 is field tested on site to ensure that after the prefabricated bridge deck 6 is ballasted on the rubber strip, the height of the high elastic modulus anticorrosion chlorinated rubber strip 1 is not less than 2cm; 6 and the outer edge of the steel beam 5 are pasted with a high elastic modulus anticorrosion chlorinated rubber strip 1 with cold vulcanization adhesive, and a high...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com