Steel truss-steel plate combined shear wall and method for producing the same

A technology of combining shear walls and manufacturing methods, applied in the direction of walls, structural elements, building components, etc., can solve the problems of large stress, impact on seismic capacity, and reduce the bearing capacity of shear walls, so as to reduce self-weight, improve bearing capacity, The effect of improving the shear capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

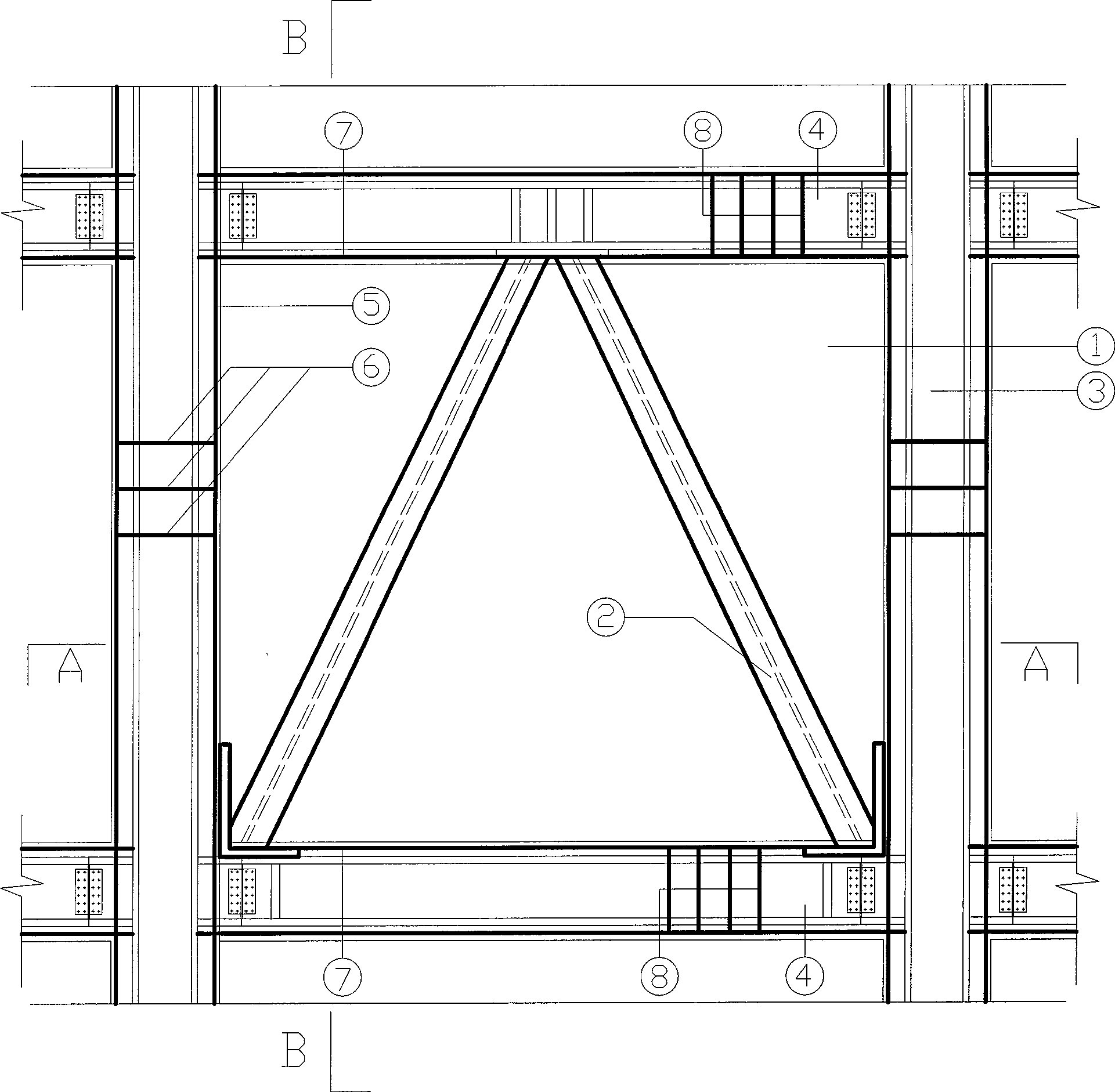

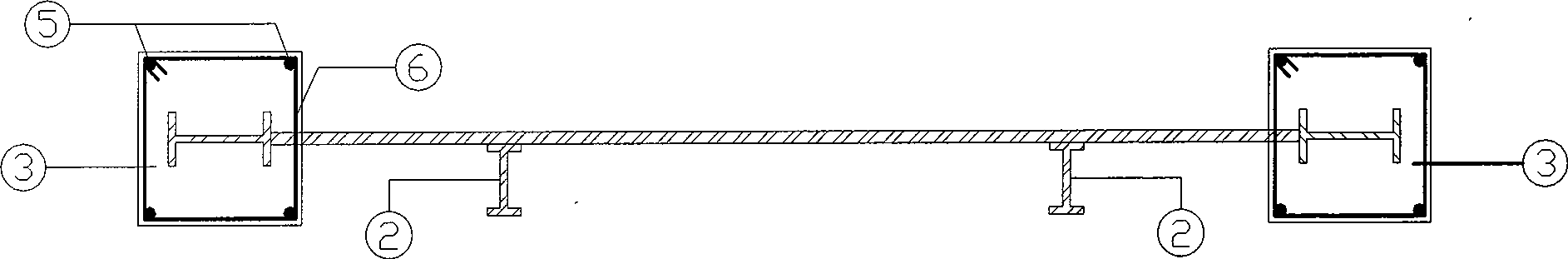

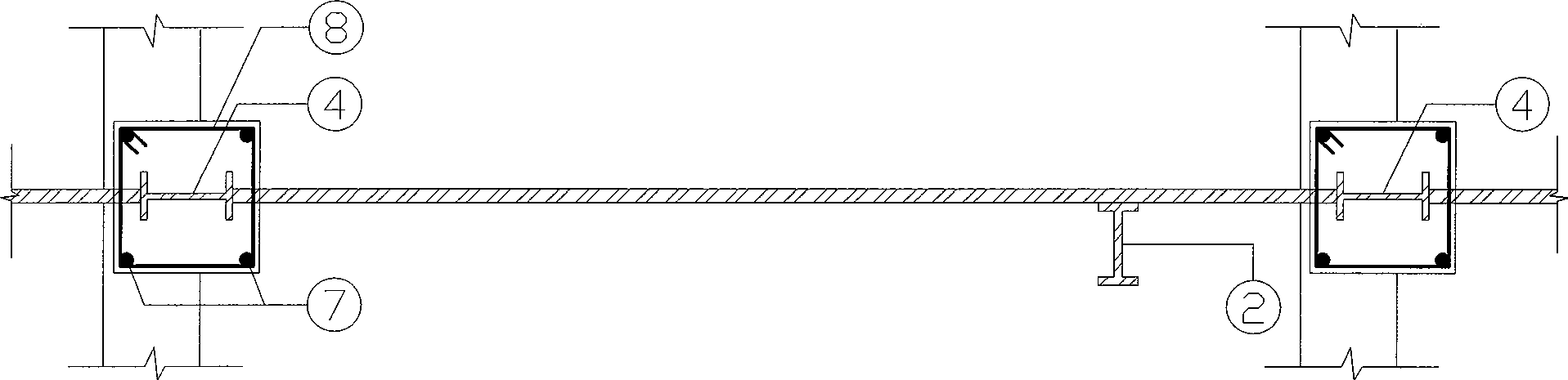

[0029] The schematic diagram of structural reinforcement of a structural unit of steel truss-steel plate composite shear wall is as follows Figure 1 ~ Figure 3 shown. This embodiment is composed of frame beams, shaped steel concrete columns 3, steel plates and shaped steel oblique supports. The two ends of the shear wall are provided with steel concrete columns 3, and the steel concrete columns 3 are consolidated with the frame beams, and a steel plate 1 is arranged between the frame beams and the frame columns, and holes or grooves are reserved on the steel plate 1. The frame beam of the shear wall is provided with a shaped steel beam 4, and the frame beam longitudinal reinforcement 7 is arranged on the periphery of the shaped steel beam 4, and the rectangular stirrup 8 is evenly bound along the frame beam longitudinal reinforcement 7, and the rectangular stirrup 8 of the frame beam passes through The reserved holes or cutting grooves on the steel plate are evenly distribut...

Embodiment 2

[0041] The structure of this embodiment is as Figure 4 As shown, it is basically the same as in Embodiment 1, the only difference is that: the shaped steel diagonal support 2 is arranged in an X shape in the plane of the steel plate, and its upper end extends into the joint between the shaped steel concrete column 3 and the upper frame beam, and is connected with the shaped steel concrete column 3 The shaped steel in the frame and the shaped steel beam 4 in the upper frame beam are connected at the same time. The lower end extends into the node of the shaped steel concrete column and the lower frame beam, and is simultaneously connected with the shaped steel in the shaped steel concrete column 3 and the shaped steel beam 4 in the lower frame beam.

Embodiment 3

[0043] The structure of this embodiment is as Figure 5 As shown, it is basically the same as that of Embodiment 1, the only difference is that the shaped steel oblique support 2 is arranged in a figure-eight shape in the plane of the steel plate, and its upper end extends into the upper frame beam and is fixedly connected with the shaped steel beam 4 in the beam, and its lower end extends Into the node of the steel concrete column 3 and the lower frame beam, and connect with the steel beam 4 in the steel concrete column 3 and the lower frame beam at the same time.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com