Carbon fiber fabric reinforced resin matrix composite girder cap and manufacturing method thereof

A technology for reinforcing resin-based and carbon fiber fabrics, which is applied in the manufacture of final products, sustainable manufacturing/processing, wind turbine components, etc., and can solve the problems of difficulty in obtaining high-performance carbon fiber spar caps, poor compressive strength, and performance limitations of composite materials, etc. problems, to meet the requirements of paving efficiency and perfusion efficiency, improve structural strength, and overcome the effect of not being resistant to medium and high temperatures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

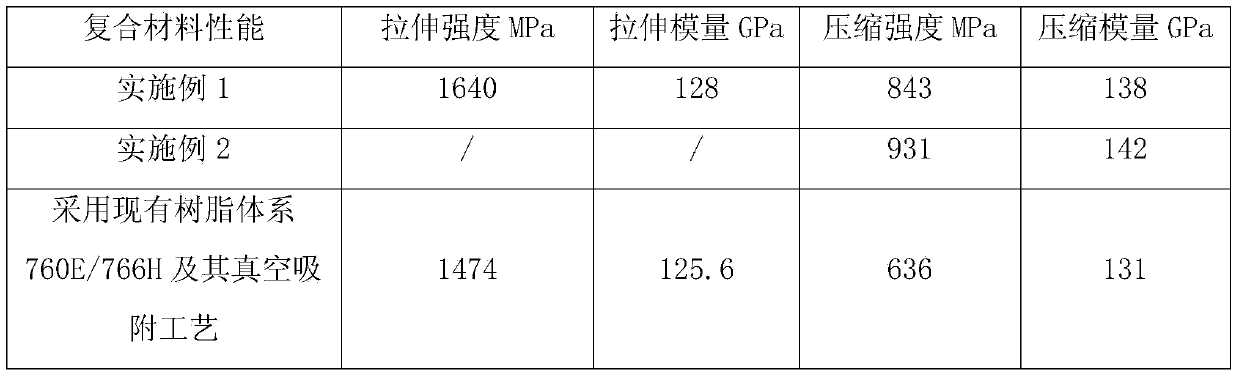

[0025] Example 1: A carbon fiber fabric reinforced resin-based composite spar cap, using carbon fiber stitched fabric as a reinforcing material, and using a glycidyl ester epoxy resin system as a matrix resin. Carbon fiber stitched fabric, the warp material is 216g / m surface weight 2 The SYT45 carbon fiber yarn, the surface weight in the weft direction is 8g / m 2 Composed of 68tex glass fiber yarns, etc., where the weft yarn spacing is 10mm; the glycidyl ester epoxy resin system uses TDE85 epoxy resin + amine curing agent.

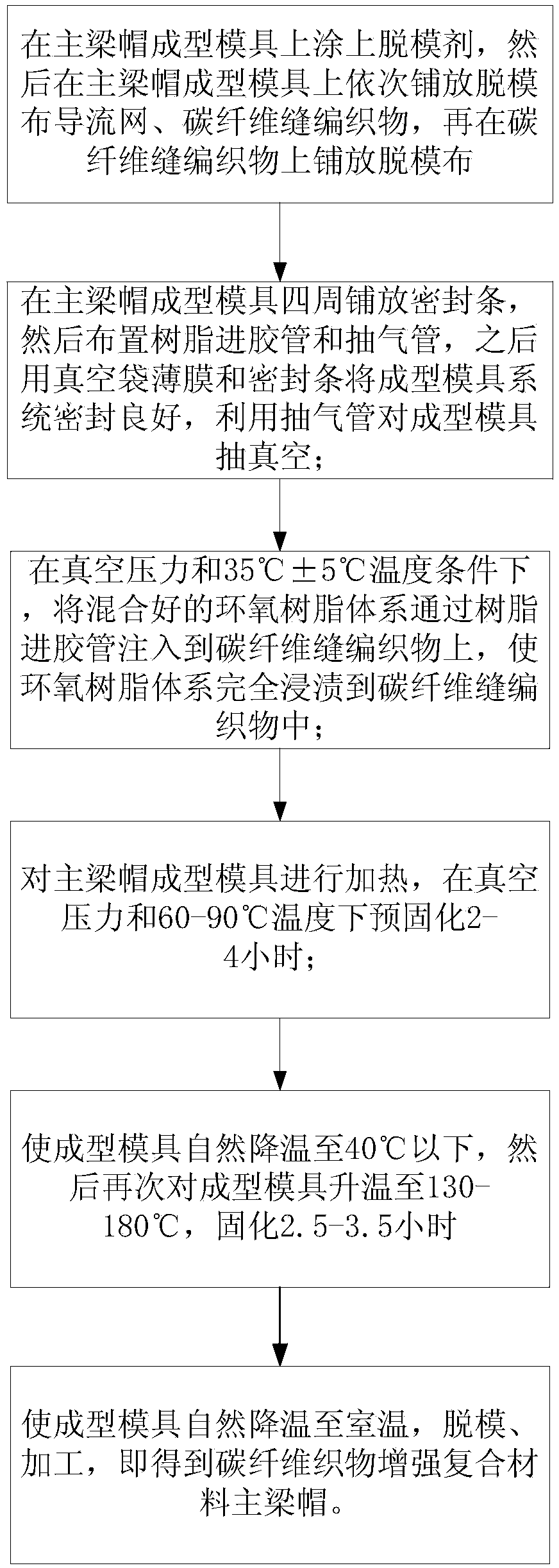

[0026] Methods of manufacturing spar caps such as figure 1 As shown, it specifically includes the following steps:

[0027] (1) First, apply a release agent on the main spar cap forming mold, then lay out process auxiliary materials such as release cloth and diversion net, and then lay the carbon fiber stitched fabric, and then lay on the carbon fiber stitched fabric in turn Put release cloth and other process auxiliary materials;

[0028] (2) Lay seali...

Embodiment 2

[0033] Example 2: A carbon fiber fabric reinforced resin-based composite spar cap, using carbon fiber stitched fabric as a reinforcing material, and using a glycidyl ester epoxy resin system as a matrix resin. Carbon fiber stitched fabric, the warp material is 216g / m surface weight 2 The SYT45 carbon fiber yarn, the surface weight of the weft direction is 8g / m 2 68tex glass fiber yarn, etc., wherein the weft yarn interval is 10mm; the glycidyl ester epoxy resin system is characterized in that the epoxy resin system is TDE85 epoxy resin+acid anhydride curing agent+accelerator.

[0034] The manufacture method of spar cap specifically comprises the following steps:

[0035] (1) First, apply a release agent on the main spar cap forming mold, then lay out process auxiliary materials such as release cloth and diversion net, and then lay the carbon fiber stitched fabric, and then lay on the carbon fiber stitched fabric in turn Put release cloth and other process auxiliary materials; ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface weight | aaaaa | aaaaa |

| Surface weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com