Construction method of main beam of steel-concrete composite beam cable-stayed bridge

A technology of steel-concrete combination and construction method, which is applied in the direction of bridges, bridge construction, erection/assembly of bridges, etc., and can solve problems such as unfavorable structural quality, combined beam installation quality and overall construction period, and high construction site requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0035] like figure 1 The construction method of the main girder of the steel-concrete composite beam cable-stayed bridge shown in -11, the steps are as follows:

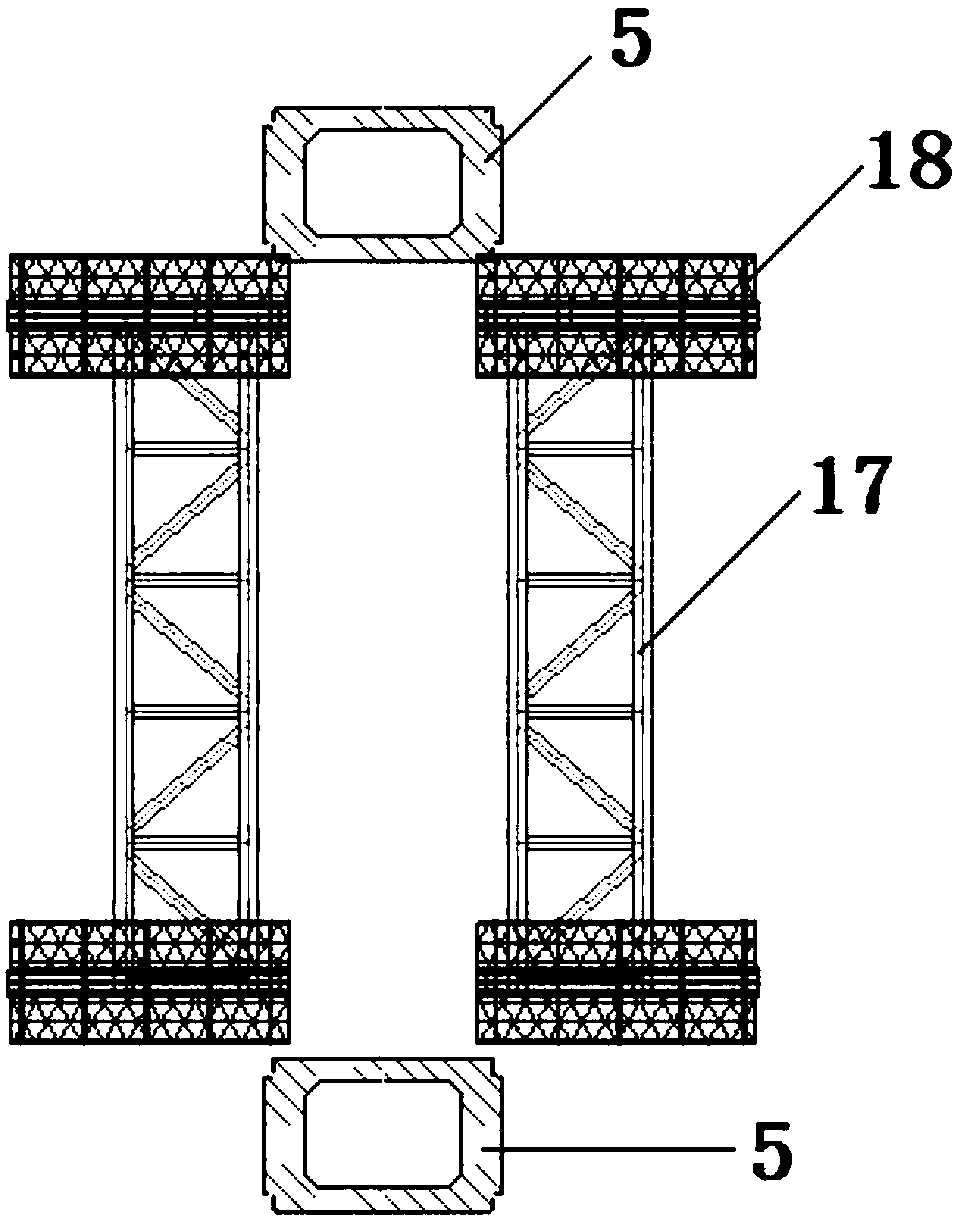

[0036]1) Install the wall-attached crane on the two cable towers 5, hoist the temporary consolidation 17 and the protection platform 18 on the wall-attached crane and install them on the cable tower 5, and erect the initial segmental steel beam on the temporary consolidation 17 3;

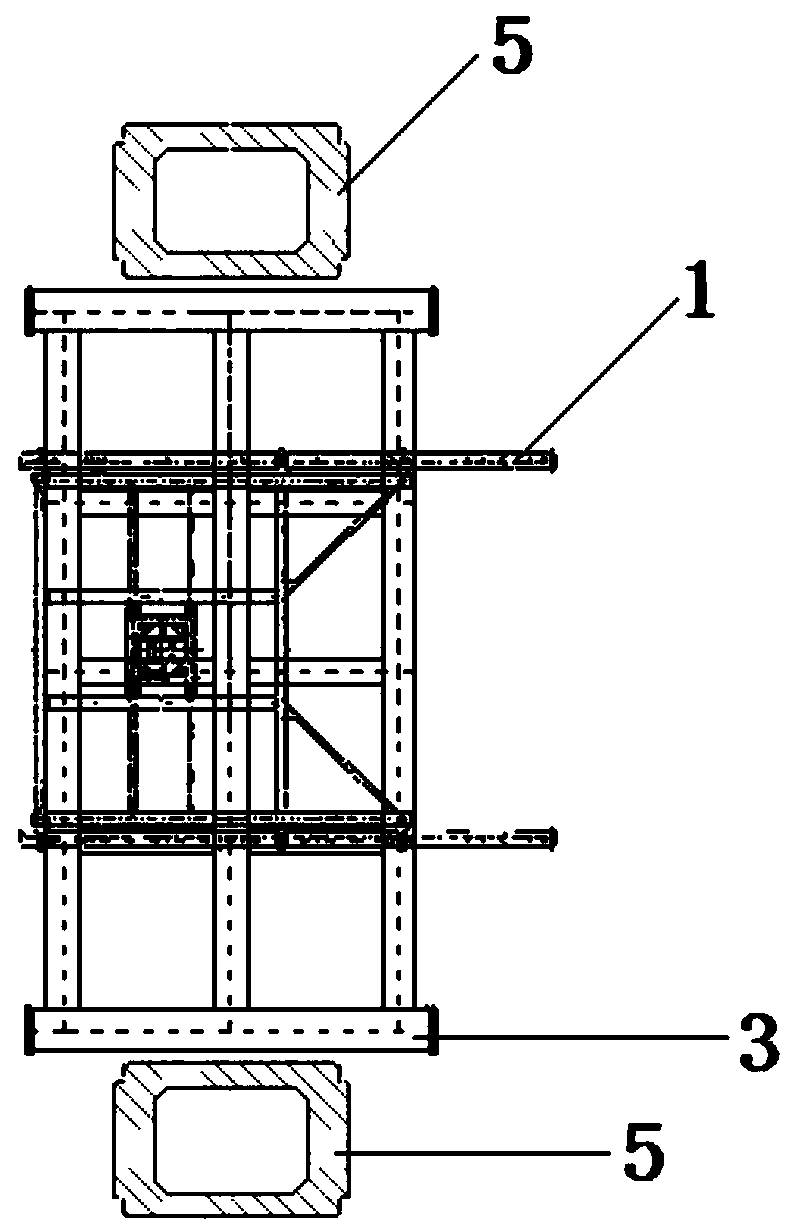

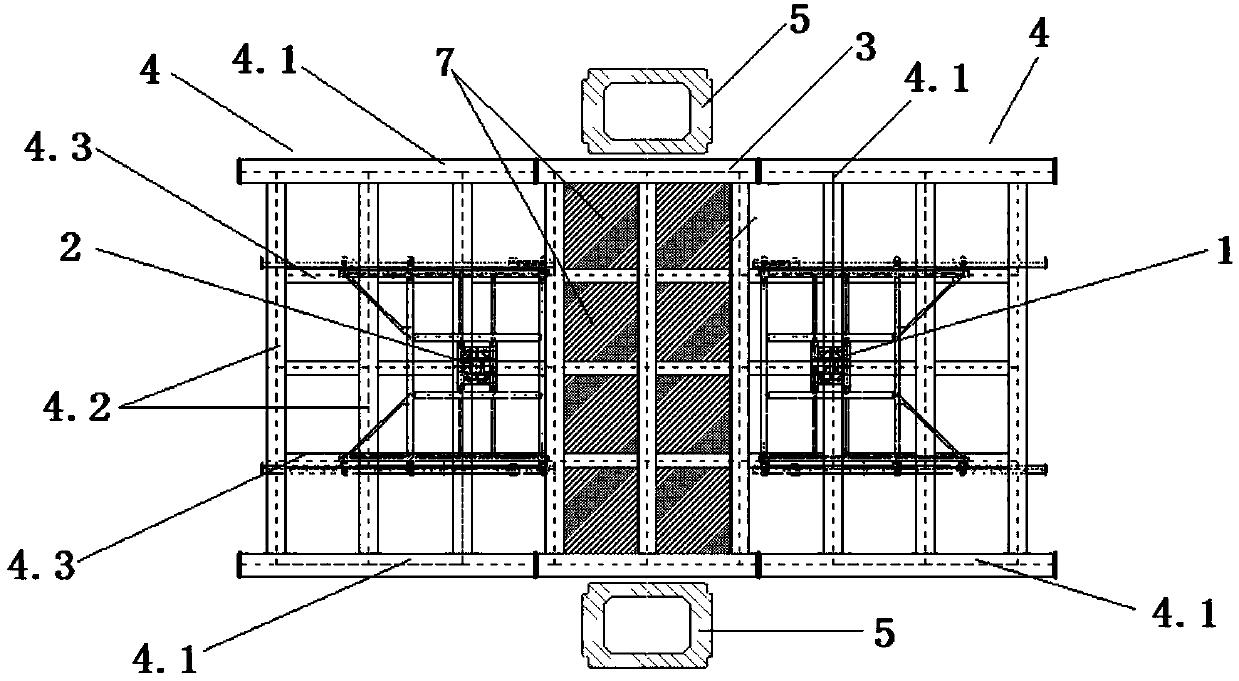

[0037] 2), hoist the first deck crane 1 to the steel girder 3 of the initial section by the wall-attached crane and fix it, and fix the steel beam 4 of the splicing section of the hoisting unit of the first deck crane 1 to the steel beam 3 of the initial section At both ends, the stay cables 6 of the steel beams 4 of the unit splicing section are installed and tensioned;

[0038] The fixing co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com