Operation platform for replacing support saddle of bridge

A technology for operating platforms and bridge supports, which is applied to bridges, bridge maintenance, bridge reinforcement, etc., can solve problems such as poor reliability, increase the area of pier tops, and expand the diameter of original bridge piers, and achieve high reliability and small damage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

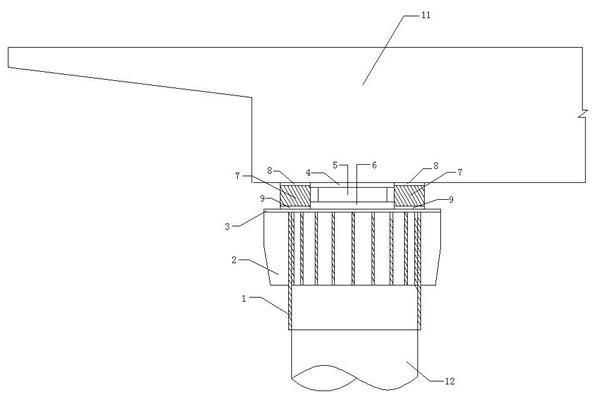

[0021] figure 1 It is a schematic structural diagram of an embodiment of the present invention in the direction of the bridge;

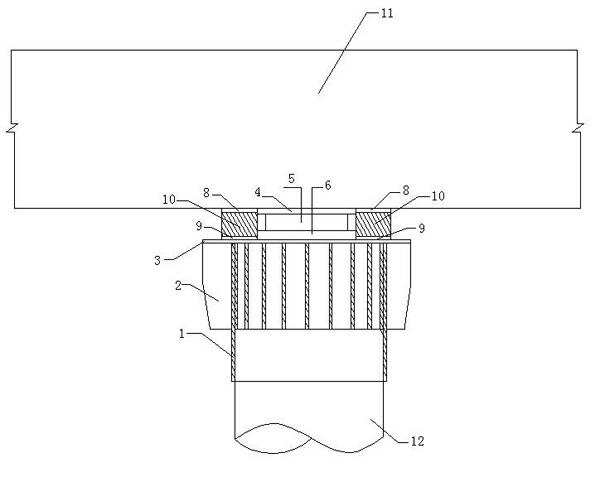

[0022] figure 2 It is a structural schematic diagram of an embodiment of the present invention in the longitudinal bridge direction;

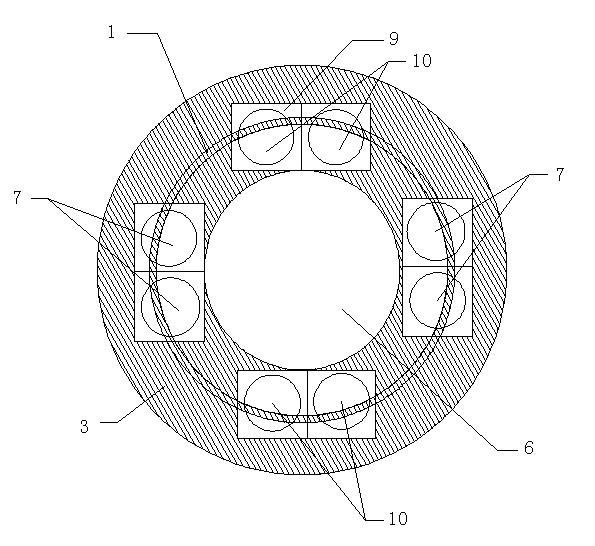

[0023] image 3 It is a schematic diagram of the planar structure of the top plate according to an embodiment of the present invention;

[0024] Figure 4 It is a schematic diagram of the planar structure of the pier hoop according to an embodiment of the present invention.

[0025] Such as Figure 1-Figure 4 Shown:

[0026] A bridge pier column 12 is arranged at the bottom of the existing bridge superstructure beam body 11, and a support 5 is arranged between the top of the bridge pier column 12 and the beam body 11, and between the support 5 and the bridge pier column 12 Pad stones 6 are provided, and wedges 4 are also provided between the support 5 and the beam body 11 .

[0027] In order to replace the da...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com