Method for lifting and installing whole bridge arch rib

A technology of overall lifting and arch ribs, which is applied in bridges, bridge construction, erection/assembly of bridges, etc., can solve the problems of poor cable hoisting accuracy, difficult hoisting, and difficult construction, so as to meet the requirements of installation quality and accuracy, reduce The difficulty of welding quality control and the effect of reducing the acquisition of construction land

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention will be further described below in conjunction with the accompanying drawings, but the protection scope of the present invention is not limited to the following examples.

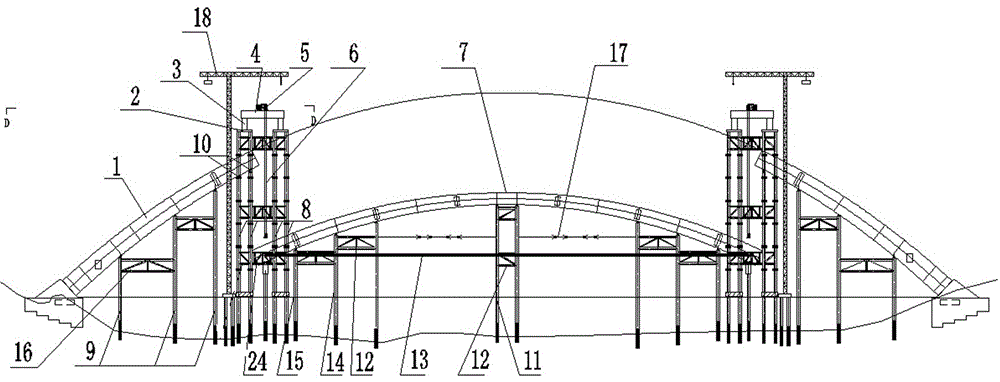

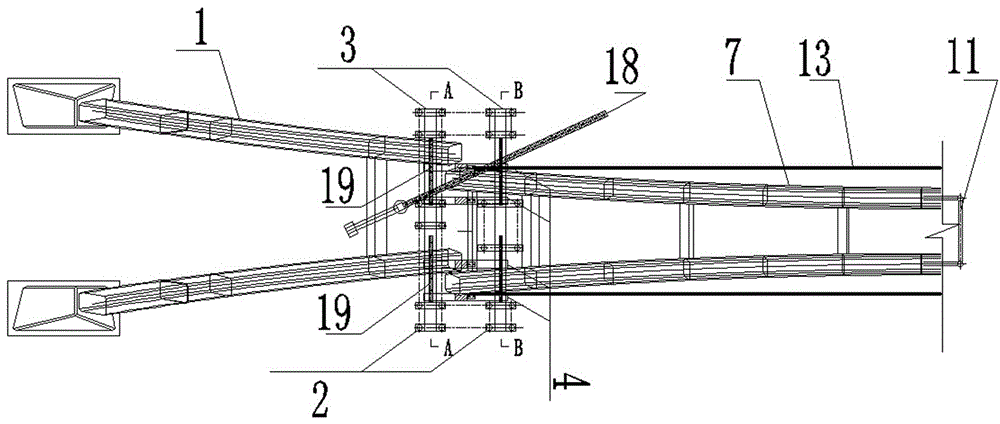

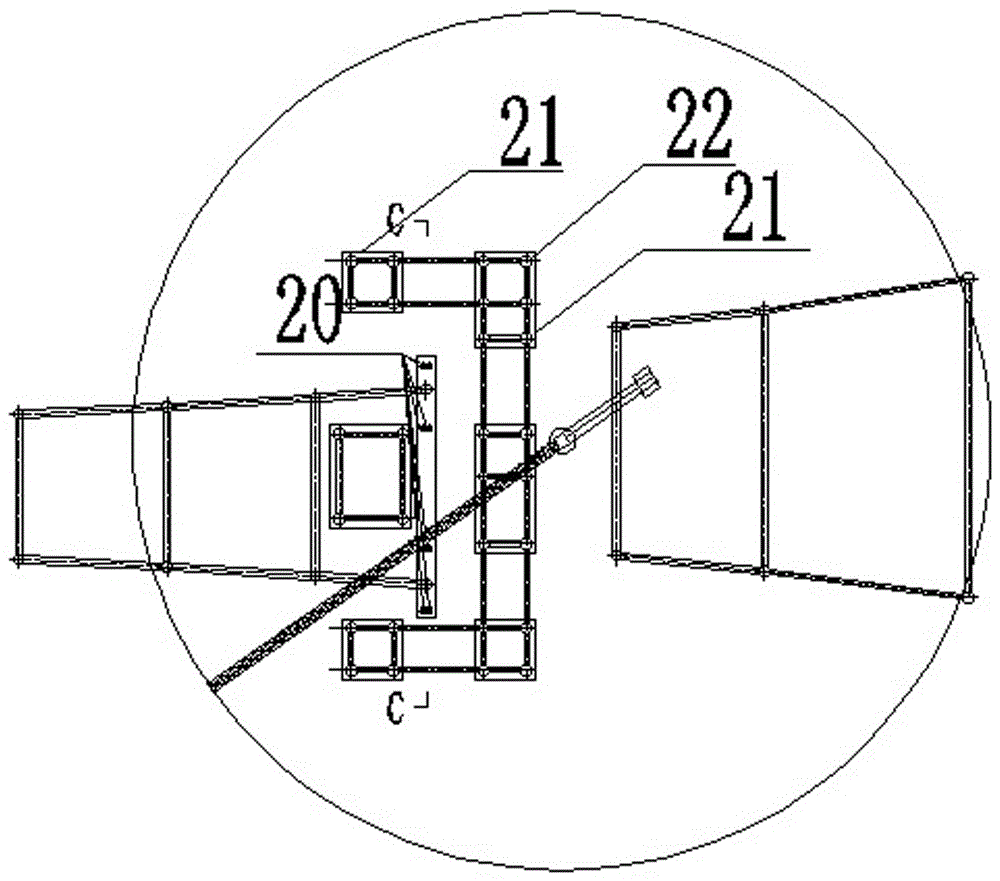

[0043] to combine figure 1 and figure 2 As shown, among them, figure 2 Only the positions of one side arch rib and half of the middle arch rib are shown, and the other half is symmetrically arranged. A method for overall lifting and installation of bridge arch ribs includes the following steps:

[0044] S1. The arch rib is divided into two side arch ribs 1 and a middle arch rib 7, and the two side arch ribs 1 are symmetrically arranged on both sides of the longitudinal central axis of the arch rib; the side arch rib 1 and the middle arch rib 7 According to the design requirements, generally the span of each side arch rib 1 accounts for 20-30% of the entire arch rib span, and correspondingly, the span of the middle arch rib 7 accounts for 60-40% of the entire arch rib;

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com