Ultrahigh flat plate unit lifting mechanism and method utilizing combined locking

A lifting mechanism, flat plate technology, applied in the direction of lifting frame, lifting device, etc., can solve the problem of limited height and space, and achieve the effect of improving the stability of the center of gravity, increasing the load potential, and improving the economy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

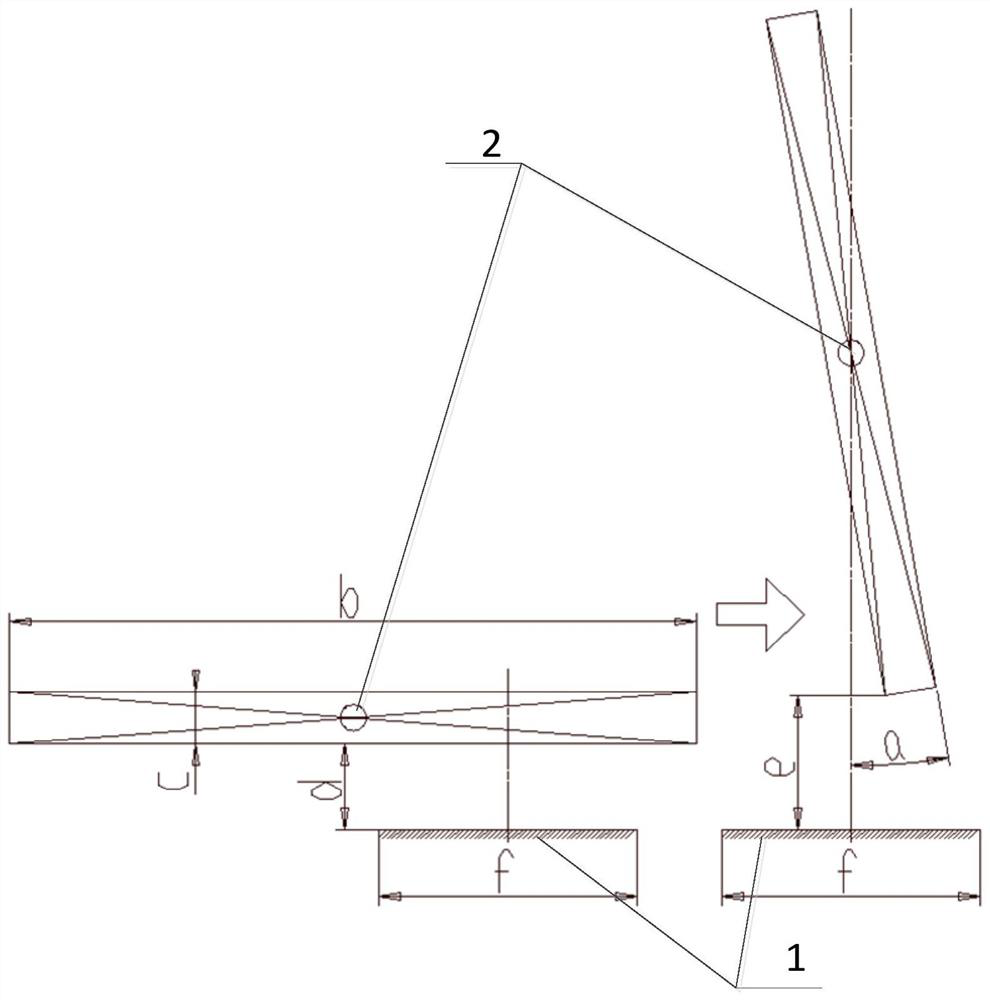

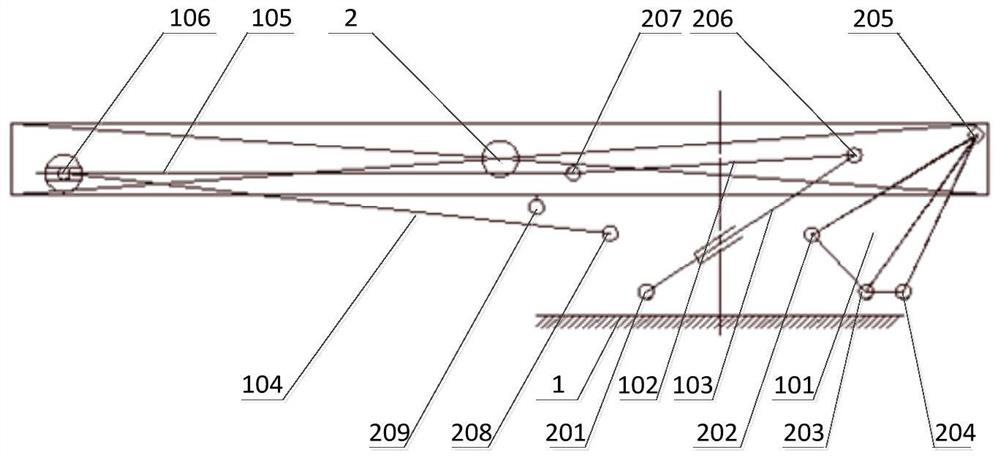

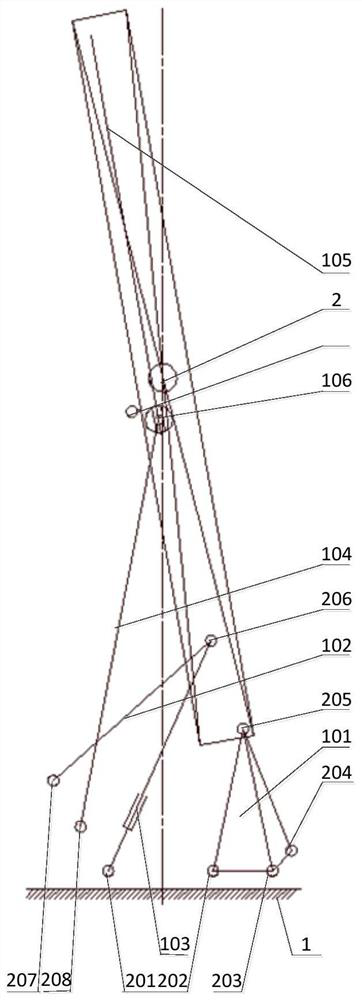

[0047] Embodiment 1: A lifting mechanism for an ultra-high flat panel unit utilizing joint locking, including an active rod 101, a passive rod 102, a locking rod 104, a slide lock 106, a slide rail 105 and a hydraulic cylinder 103, the hydraulic cylinder 103 pushes the super-high flat panel After the unit is raised in place, the active lever 101 completes the locking, and the slide lock 106 located on the slide rail 105 is locked to realize the spatial position locking of the ultra-high flat panel unit; the locking lever 104 is used to provide a stable resistance to the ultra-high flat panel unit. wind moment

Embodiment 2

[0048] Embodiment 2: On the basis of Embodiment 1, the core 2 of the ultra-high flat panel unit is located on the center line of the bottom surface 1.

Embodiment 3

[0049] Embodiment 3: On the basis of Embodiment 1, the active rod 101 is composed of a quadrilateral area formed by connecting the second node 202 , the third node 203 , the fourth node 204 and the fifth node 205 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com