Construction method of unfolding and putting guide rope by helicopter without shipping stoppage

A construction method and helicopter technology, applied to aircraft parts, delivery of filamentous materials, launching devices, etc., can solve the problems of low shipping density, backward stringing equipment, and insignificant impact on water transportation, etc., and achieve wind resistance and stability good sex effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The technical solutions of the present invention will be further described in detail below with reference to the accompanying drawings.

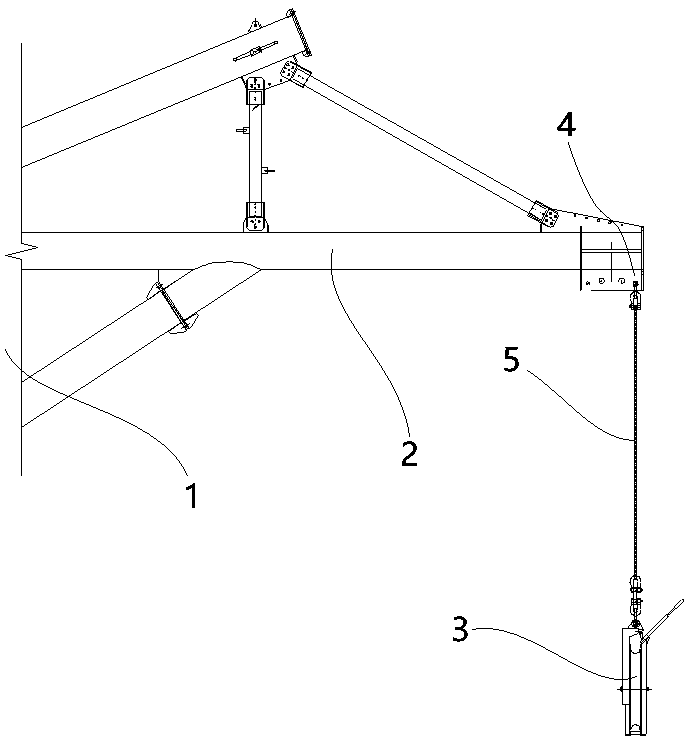

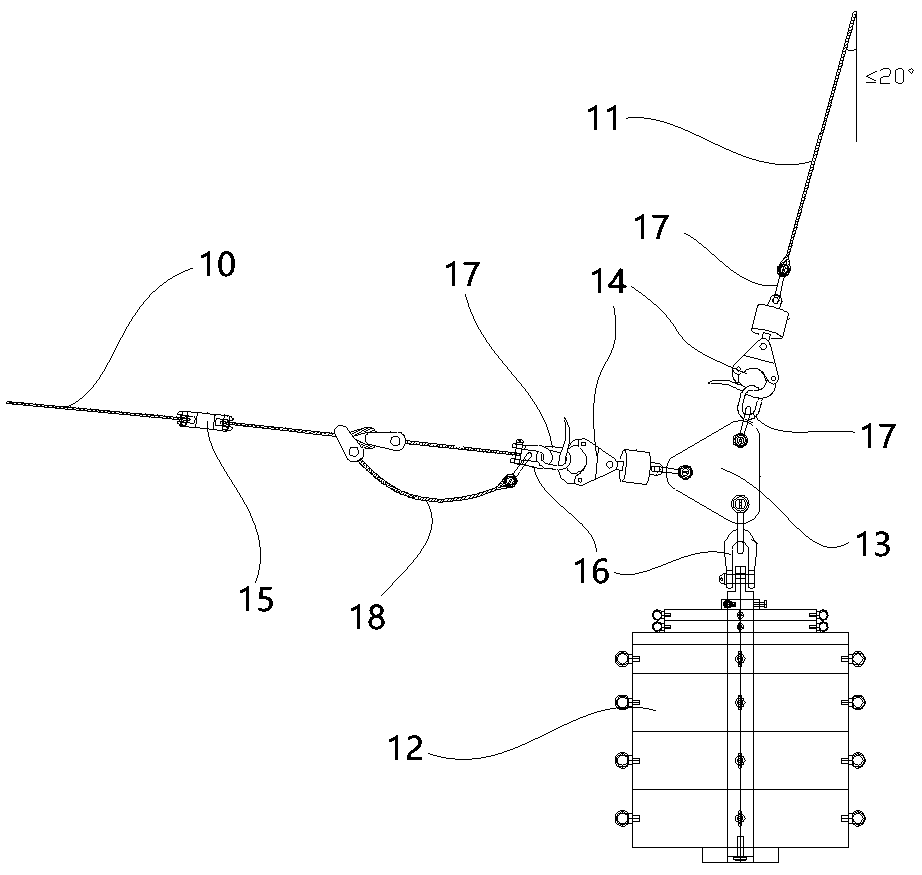

[0035] like Figure 1-6 As shown in the figure, a construction method for pulling and releasing a guide rope without a closed helicopter includes the following steps:

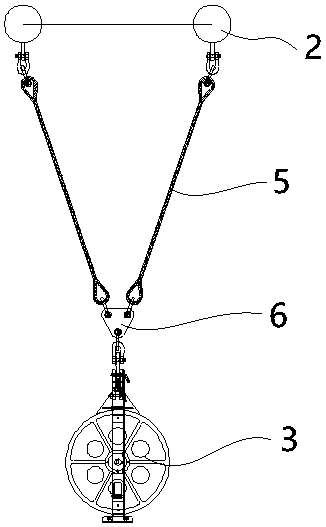

[0036] 1) On the ground wire brackets 2 on the left and right sides of the two bases 380m across the tower 1, respectively hang the 305-type pay-off pulley 3 for the helicopter pay-off special guide rod, and hang one pay-off pulley 3 on each side; the pay-off pulley 3 passes through The triple plate 6 and the steel wire sleeve 5 are connected to the construction plate 4 under the front and rear main pipes at the hanging point of the iron tower in a V-type connection. The pay-off block 3 is connected to the V-shaped steel sleeve 5 through the triple plate 6 in a single-point shackle connection. The steel wire sleeve 5 Use two Ф22×2.5m galvanized pressed steel wire slee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com