Reverse buckling cable reinforced large-span suspension bridge and reasonable bridge forming state determination method

It is a technology of bridge-building state and suspension bridge, which is applied in the direction of suspension bridge, bridge, bridge form, etc. It can solve the problems of wind resistance stability and other problems, and achieve the effect of increasing the structural economic span, improving the stress state, and increasing the vertical stiffness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

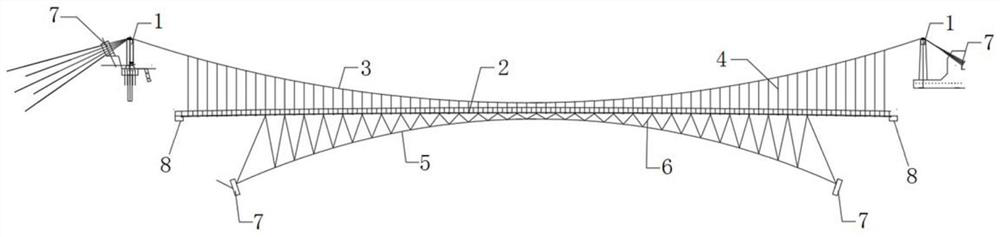

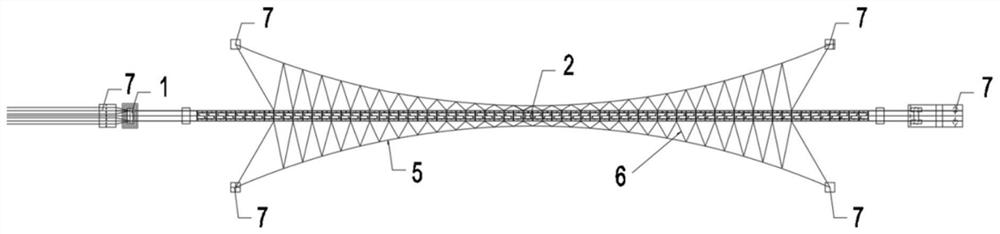

[0040]The anti-cable reinforced long-span suspension bridge of this embodiment is as follows: figure 1 , figure 2 As shown, it includes bridge tower 1, main girder 2, main cable 3, suspender 4, buckle cable 5, wind-resistant stay cable 6, anchorage 7 and other components, and the two ends of main cable 3 and buckle cable 5 pass through the anchorage 7 is fixed, and several bearings 8 are arranged symmetrically under both sides of the main beam 2.

[0041] The main cable 3 is 20m in height and 248m in span, using 7 galvanized steel wire ropes with a nominal diameter of 48mm; the buckle cable 5 has a span of 186m, a sag height of 20m in the vertical plane, and 19.28m in the horizontal plane, and is symmetrically arranged with one 48mm galvanized steel wire rope on the left and right , with an inclination angle of 30° to the horizontal. The upper end of the suspender 4 is connected with the main cable 3, and the lower end is connected with the main beam 2, and the arrangement ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com