Method of construction of large floating inspection doors

A construction method and inspection door technology, which is applied in the construction field of hydraulic gates, can solve the problems that lifting equipment cannot meet the requirements, increase the difficulty of anti-corrosion construction, etc., and achieve the goal of reducing calibration workload, shortening construction period, and reducing welding deformation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

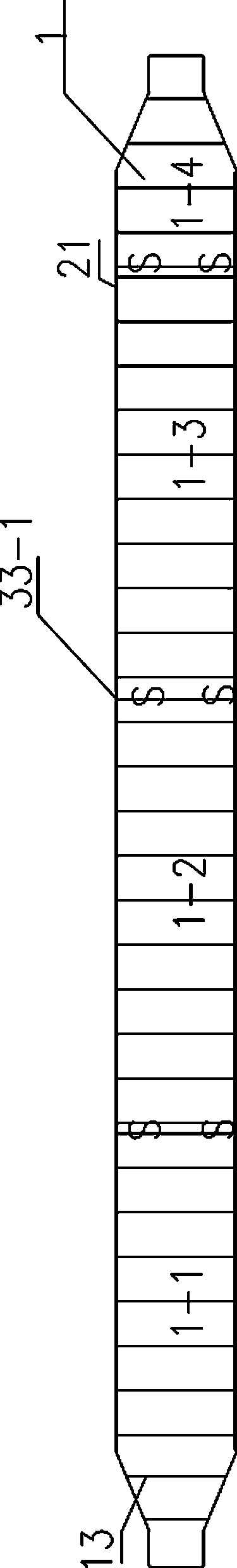

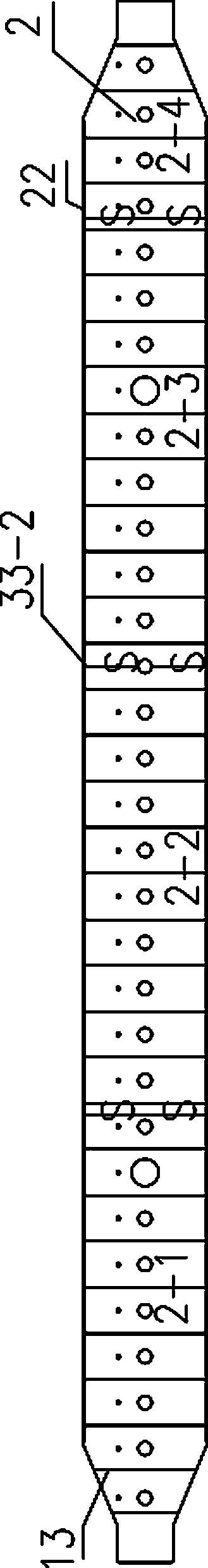

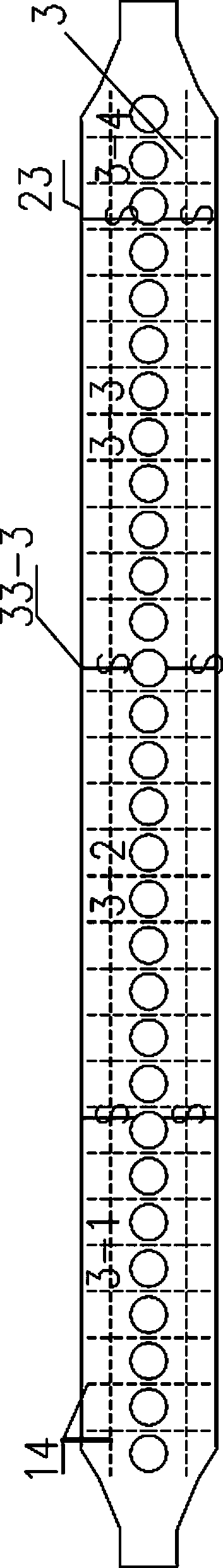

[0078] A method for constructing a large floating inspection door, the method comprising the following steps:

[0079] Step 1: Assemble the first beam body, the second beam body, the third beam body, the fourth beam body, the fifth beam body and the sixth beam body, the first beam body, the second beam body, the third beam body, The fourth beam body, the fifth beam body and the sixth beam body are all equipped with matching non-welded beam body segment lines;

[0080] Step 2: Assembling the truss 7, the truss 7 is provided with a non-welded truss segment line matching the beam body segment line;

[0081] Step 3: Assemble side column 18;

[0082] Step 4: Assemble the first beam body, the second beam body and the third beam body to obtain the lower half of the inspection door;

[0083] Step 5: Assemble the fender 11 on the truss 7 to obtain the intermediate body of the inspection door;

[0084] Step 6: Assemble the fourth beam body, the fifth beam body and the sixth beam body...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com