Pouring method of coupled shear wall structure

A pouring method and shear wall technology, which are applied in building construction, building material processing, construction, etc., can solve the problems of material and manpower consumption, high labor intensity of operators, long construction time, etc., and save manpower and construction costs. , The pouring method is simple and easy, and the effect of expanding the construction work surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

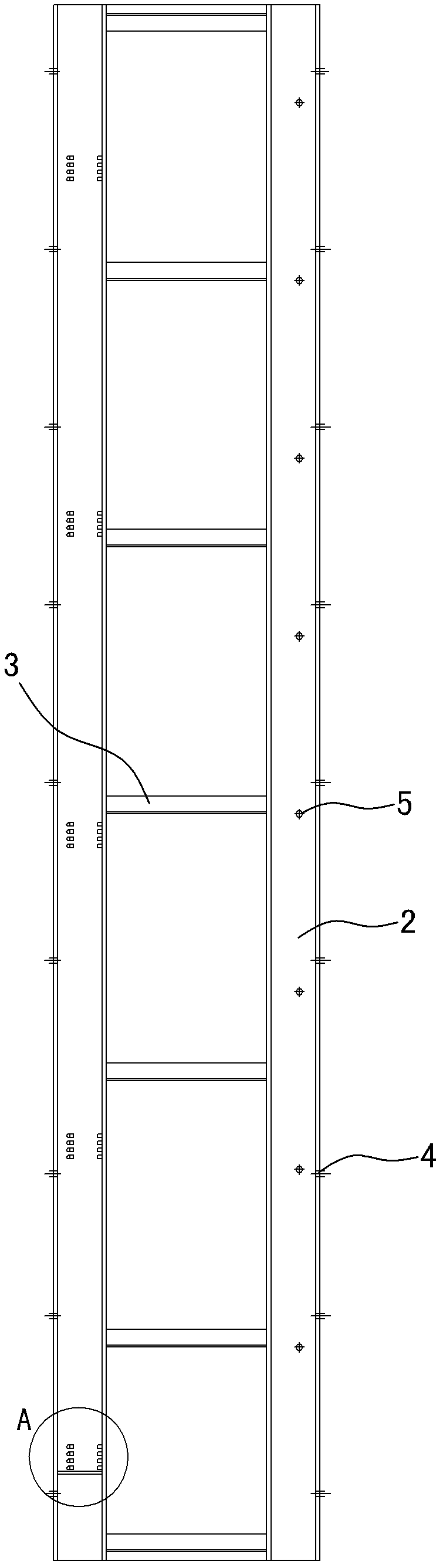

[0044] see Figure 1~8 As shown, a pouring method for a double-leg shear wall structure, the specific process is as follows:

[0045] Pre-assembly of the left formwork → positioning and setting off → installation of the positioning device of the left formwork → installation of the door opening formwork → installation of the left formwork → installation of the diamond-shaped formwork support → adjustment of the left formwork, installation of pull bolts → installation of the right formwork → adjustment Formwork on the right side, fastening the tension bolts→acceptance→layered and symmetrical pouring of concrete→curing concrete→removing formwork→cleaning.

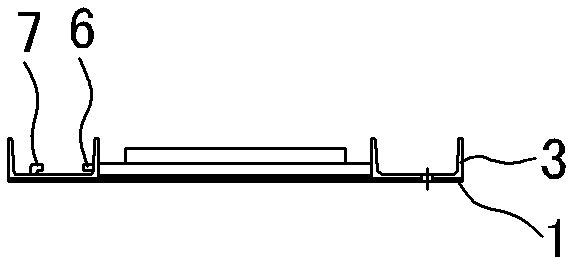

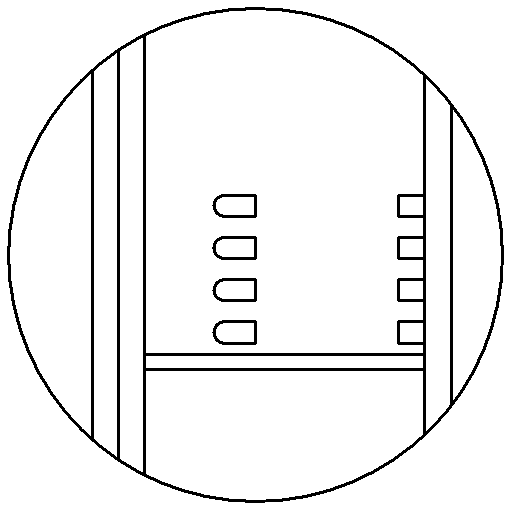

[0046] Both the left side formwork and the right side formwork are assembled by a plurality of formwork basic units through bolts or bolts, and the formwork basic units include panels 1, 2 channel steels 2 and 7 angle steels 3;

[0047]The two channel steels are arranged in parallel at both ends of the panel, and the bottom p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com