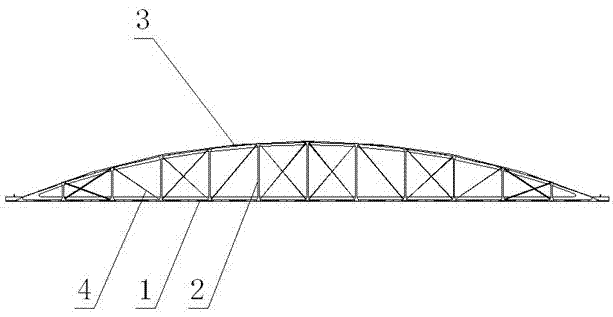

Construction method for reinforced concrete arched roof of grain store

A reinforced concrete and construction method technology, applied in the direction of construction, building structure, and building material processing, can solve the problems of unfavorable quality control, low construction efficiency, high cost of machinery use, etc., and achieve timely and reasonable and compact construction of on-site material supply process and the effect of reducing the cost of machinery usage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

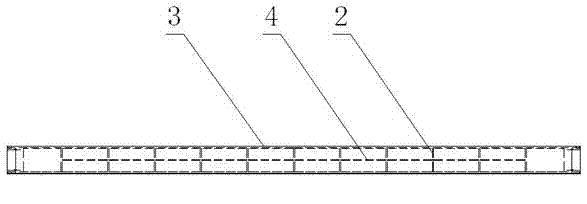

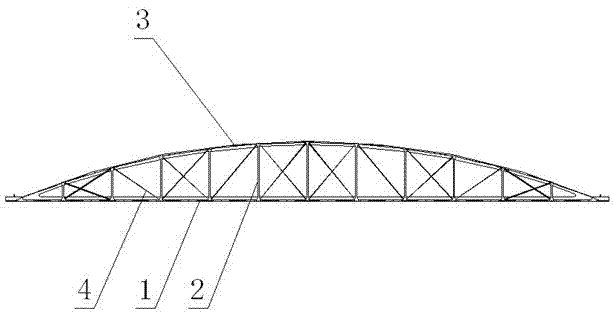

[0028] The present invention will be described in further detail below in conjunction with the drawings and specific embodiments.

[0029] The construction method of granary reinforced concrete arched roof includes the following steps:

[0030] 1) Pre-embed steel plates on the ring beams of the arched roof to be installed; at the same time, make partitions.

[0031] 2) Set up a scaffold in the longitudinal middle of the ring beam to make a pedestal of prefabricated pre-stressed arch plates in the air, and set up reserved holes for installing jacks at both ends of the pedestal. Generally, two reserved holes for installing jacks are provided at both ends of the pedestal.

[0032] 3) Lay the lower chord prestressed steel bars, and prestress the lower chord prestressed steel bars. When the lower chord prestressed steel bar is stretched, the prestressed steel bar is stretched in the order from the middle to the two sides and from bottom to top.

[0033] 4) After the lower chord prestre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com