Construction method applicable to intersection between inclined shaft and slant hole of weak surrounding rock tunnel

A technology of weak surrounding rock and construction method, applied in tunnels, earth-moving drilling, mining equipment, etc., can solve the problems of high construction cost, large amount of support, and many procedures, so as to reduce construction cost, improve construction progress, and improve the overall good performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

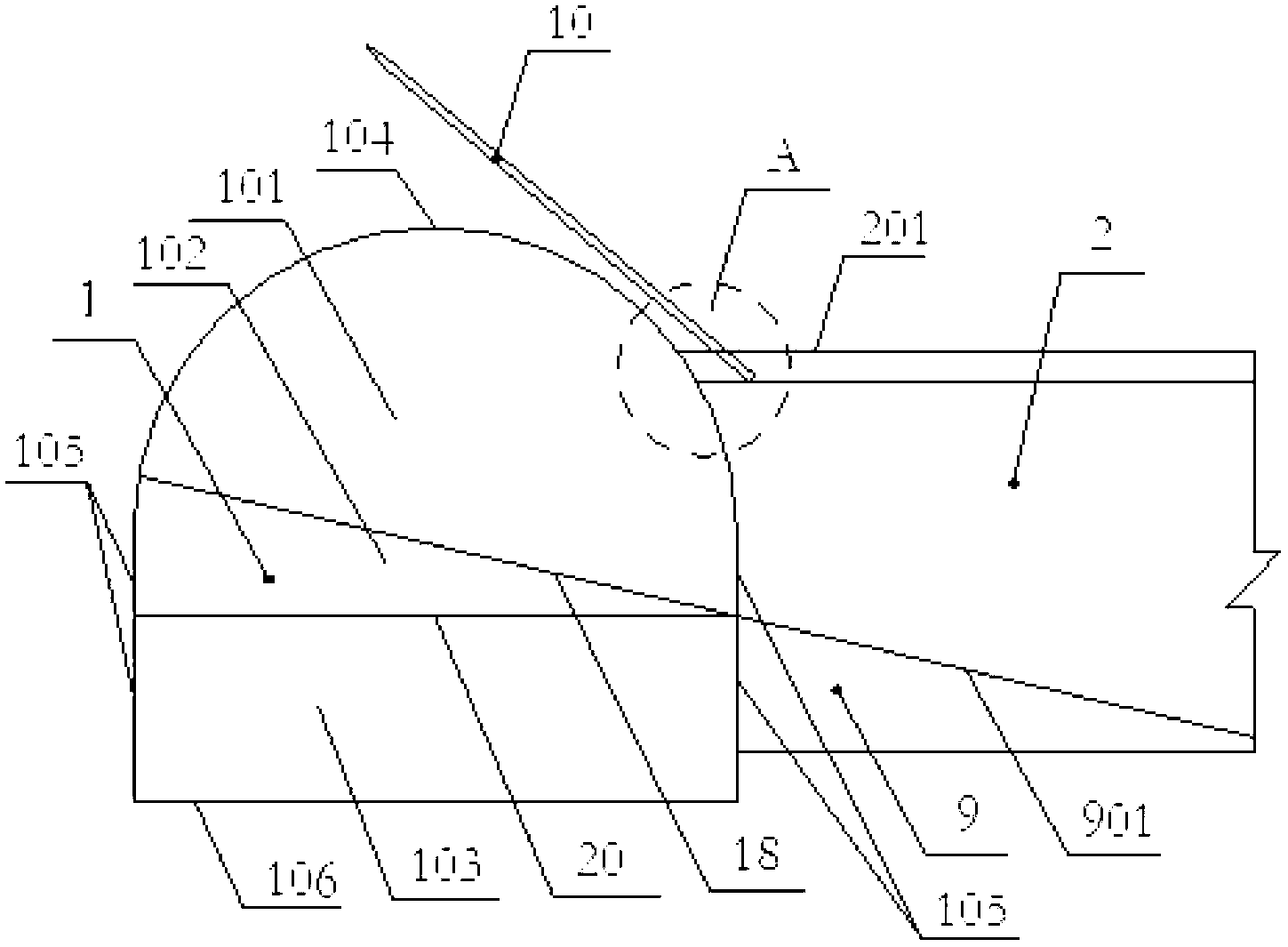

[0042] Example 1 Reference Figure 1~4 , Applicable to the construction method of the intersection of the inclined shaft and the main tunnel of the soft rock tunnel, including the following steps:

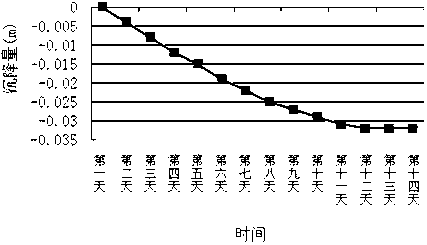

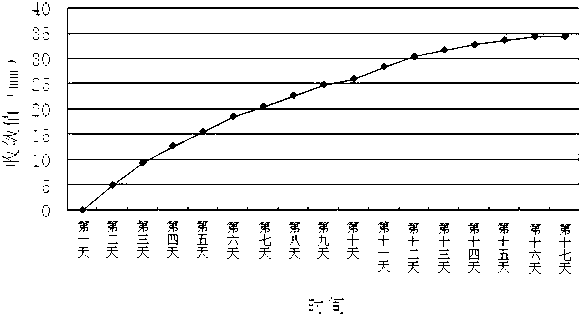

[0043] (1) Excavation of Inclined Shaft 2: Excavation of Inclined Shaft 2 and supporting it, at the intersection of Inclined Shaft 2 and Main Tunnel 1 on the tunnel face 3.5m down from the vault of Inclined Shaft 2 (see Figure 4 , Figure 4 Middle L is 3.5m) Start to backfill the cave slag towards the inlet of the inclined well 2, and pave the slope 9 with a slope of 10%;

[0044] (2) Construction of the leading small duct 10: at the arch of the tunnel face at the intersection of the inclined shaft 2 and the main tunnel 1, a 2 / 3 inclined centered on the vertical midline of the tunnel face at the intersection of the inclined shaft 2 and the main tunnel 1. A 5m-long lead tube 10 is applied within the width of the well, the circumferential distance between adjacent lead tubes is 35cm, and ...

Embodiment 2

[0053] Example 2 Take the construction of the intersection of the inclined shaft and the main tunnel of a single-track tunnel with weak surrounding rock and loess as an example, refer to Figure 1~4 , Applicable to the construction method of the intersection of the inclined shaft and the main tunnel of the soft rock tunnel, including the following steps:

[0054] (1) Excavation of inclined shaft 2: Excavation of inclined shaft 2 for support. The construction steps of the support are: first sprayed concrete closed arch wall → anchor rod → hang steel mesh → install steel arch → Compound sprayed concrete closed arch, when bolting operation, use R25 hollow grouting bolts with a length of 2.5m, arranged in a plum blossom shape at a distance of 1.2×1.2m, and use cement mortar of strength grade M20 (with cement and sand) The weight ratio is 1:1) Pouring the anchor rod, the grouting pressure during pouring is 0.5~1.0Mpa; the inclined shaft 2 and the main tunnel 1 are obliquely crossed, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Wall thickness | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com