Oblique-crossing inclined shaft upper arc guide top brushing construction method for soft crushed rock layer

A construction method and technology for inclined wells, which are applied in wellbore lining, shaft equipment, earth-moving drilling, etc., to achieve the effect of saving cost, large space, and speeding up construction progress.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

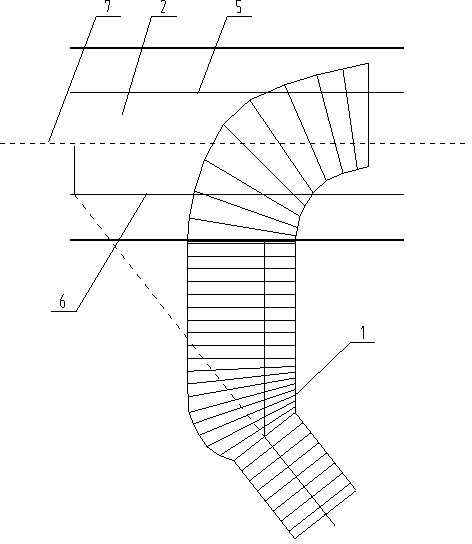

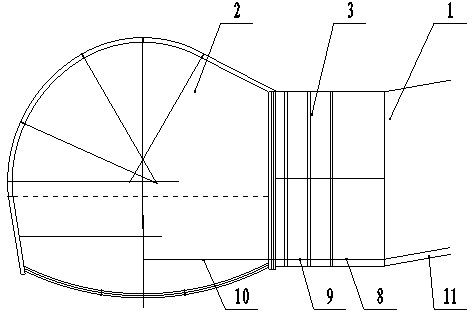

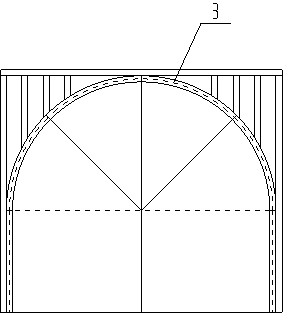

[0031] The whole tunnel of Wujialing Tunnel, a railway passage in the central and southern parts of Shanxi Province, is mainly composed of sandstone, argillaceous sandstone and mudstone. It is strongly weathered to weakly weathered, joints and fissures are developed, the rock mass is broken and the structure is loose. The intersection of No. 1 inclined shaft and the main tunnel is rich in water , the vault is easy to lose blocks and collapse, it is a weak and broken rock formation, and the inclined well and the main hole are obliquely intersected. It is designed as a small guide hole roofing scheme, and a shed hole is provided for temporary support.

[0032]After analysis, the surrounding rock structure of the overhanging section is complex, the rock mass is broken, and the water is rich, and the safety risk is extremely high. If the design of the roof is adopted, the main problems are: the temporary support section of the steel arch shed for the small pilot tunnel is trapezoi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com