Treatment method for fault fracture zone collapse in tunnel construction process

A technology of tunnel construction and broken zone, which is applied in the direction of tunnel, tunnel lining, earthwork drilling and mining, etc. It can solve the problems of surrounding rock settlement and deformation, failure of installation of pipe shed, and difficulty in drilling, so as to reduce investment, ensure safety and Permanent, avoids the effect of drilling work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

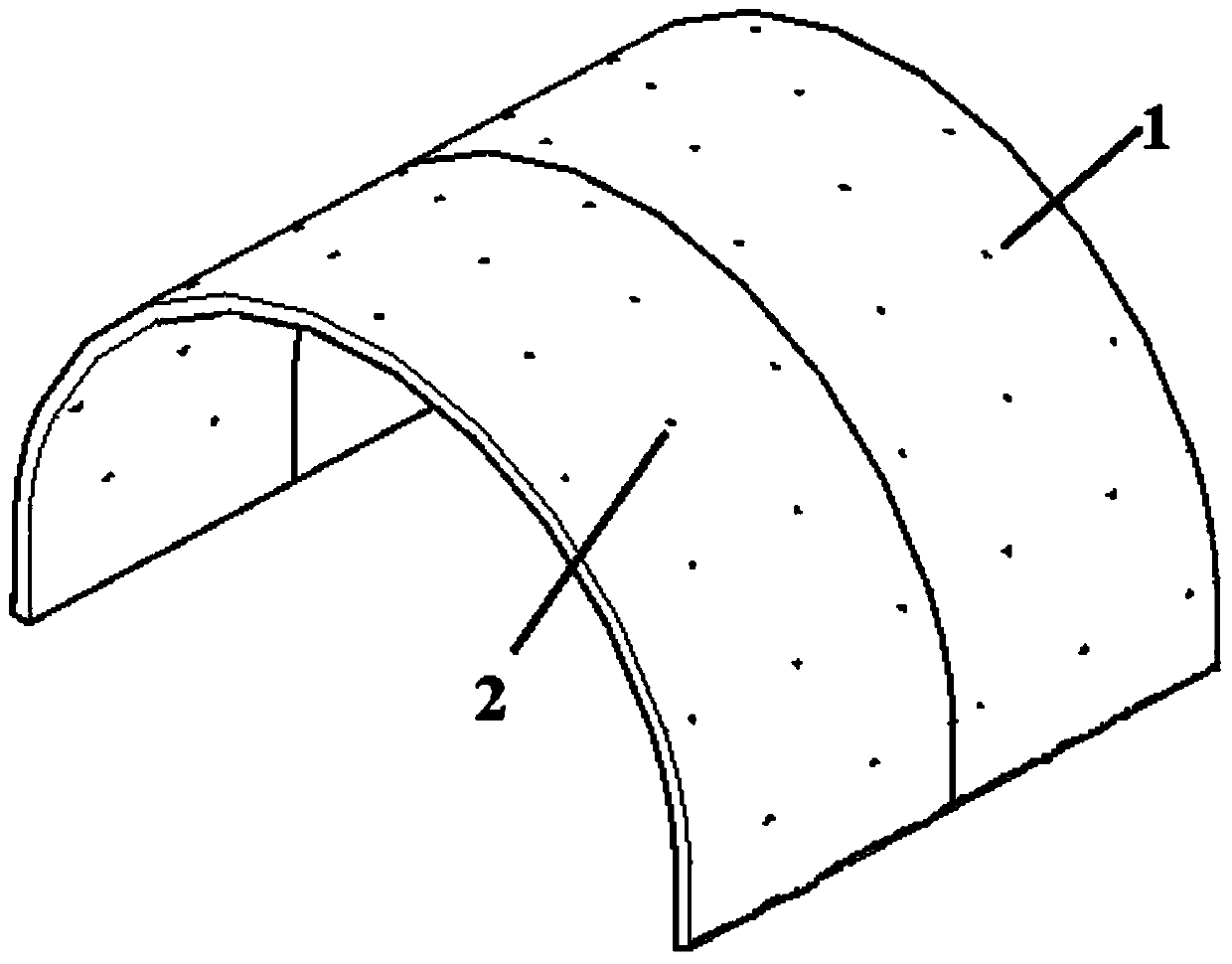

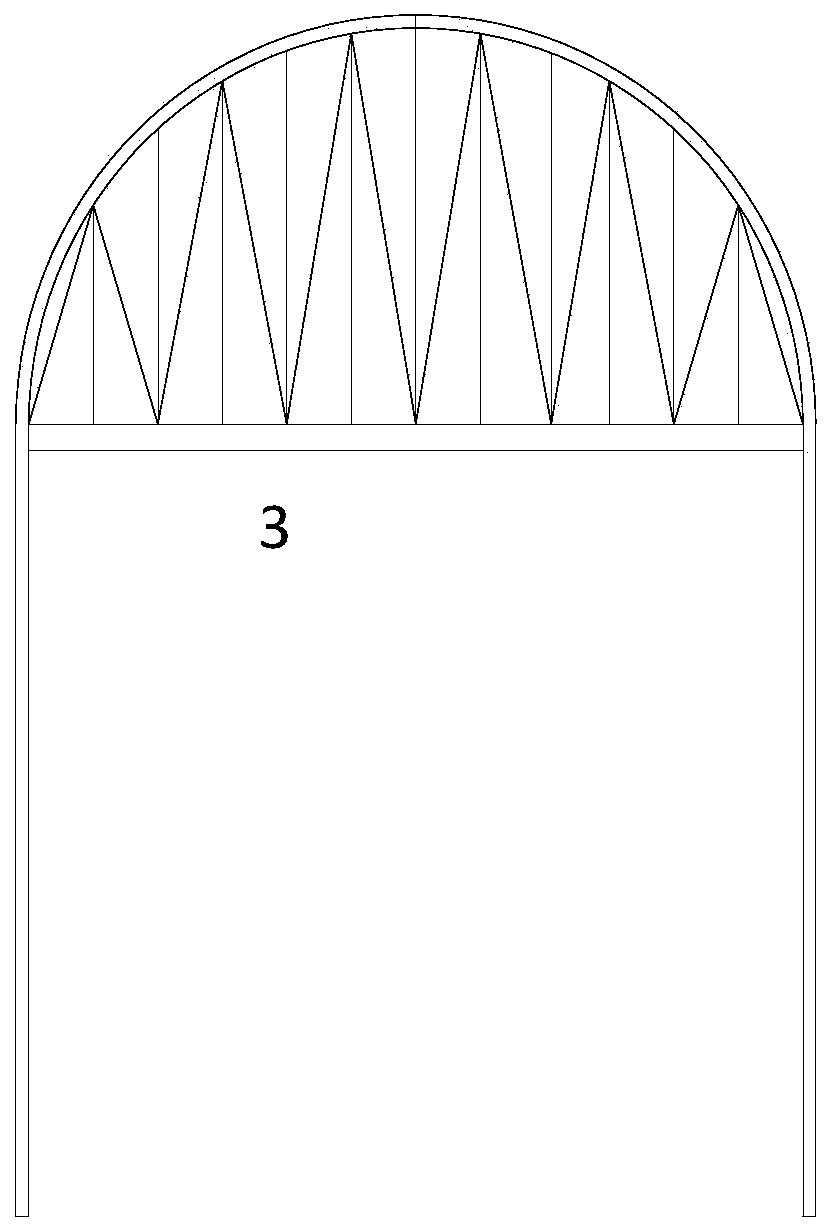

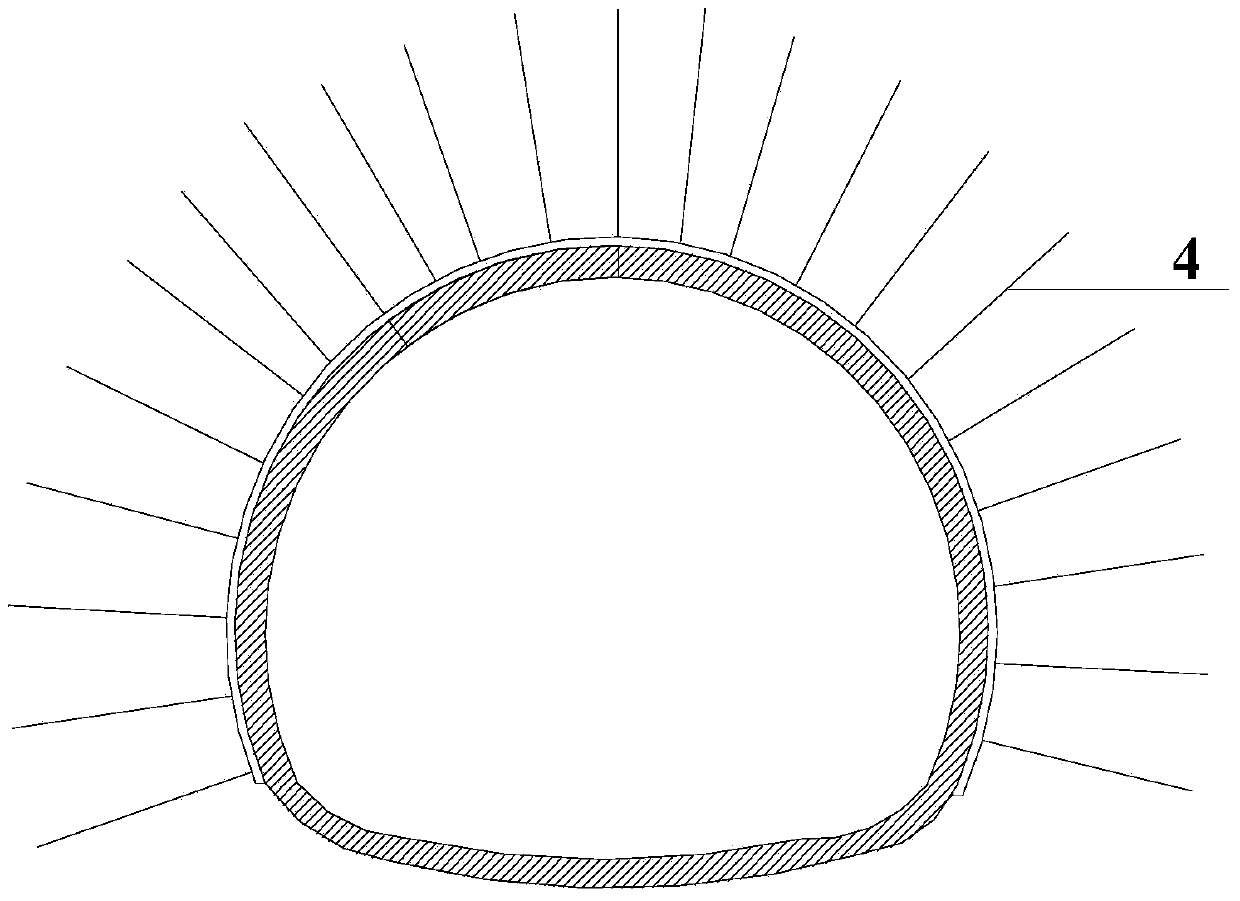

[0032] Attached below Figure 1-4 , taking the collapse treatment of the sudden fault fracture zone of a tunnel as an example, the method and construction steps of the collapse treatment of the fault fracture zone during the tunnel construction process are explained in detail.

[0033] Construction preparation stage:

[0034] According to the design and processing of 5 tunnel support formworks, the formwork size is 5.5m in inner radius, 0.9cm in thickness, 1.5m in hole-to-hole spacing, 2.5cm in hole radius, and 1.8m in formwork length. Weld 5 formwork support platforms, the steel formwork support height is 8.5m, and the width is 11m. Workers will be trained in advance on construction methods and safe operation drills will be conducted. Prepare the required steel skeleton, jacks, grouting materials, concrete and ensure the performance of the required mechanical equipment in good condition.

[0035] Phases of the construction process:

[0036] ①Firstly, the surrounding rocks...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Inner radius | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com