CRD construction method tunnel waterproof construction method

A construction method and tunnel technology, which is applied in tunnels, tunnel linings, earthwork drilling, etc., can solve the problems of large support settlement deformation, large investment, and long period of removing temporary supports, so as to reduce construction costs and shorten construction periods Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

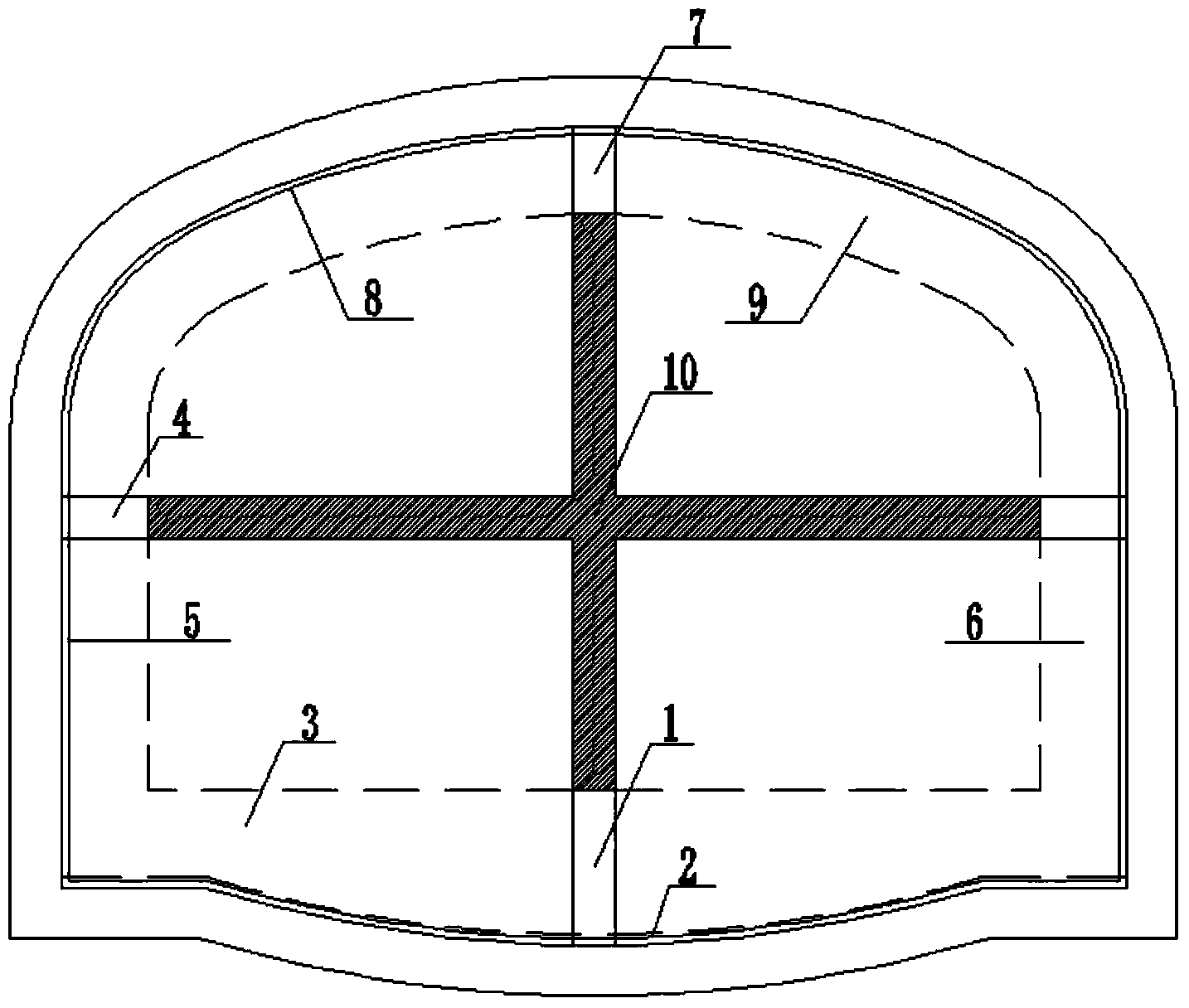

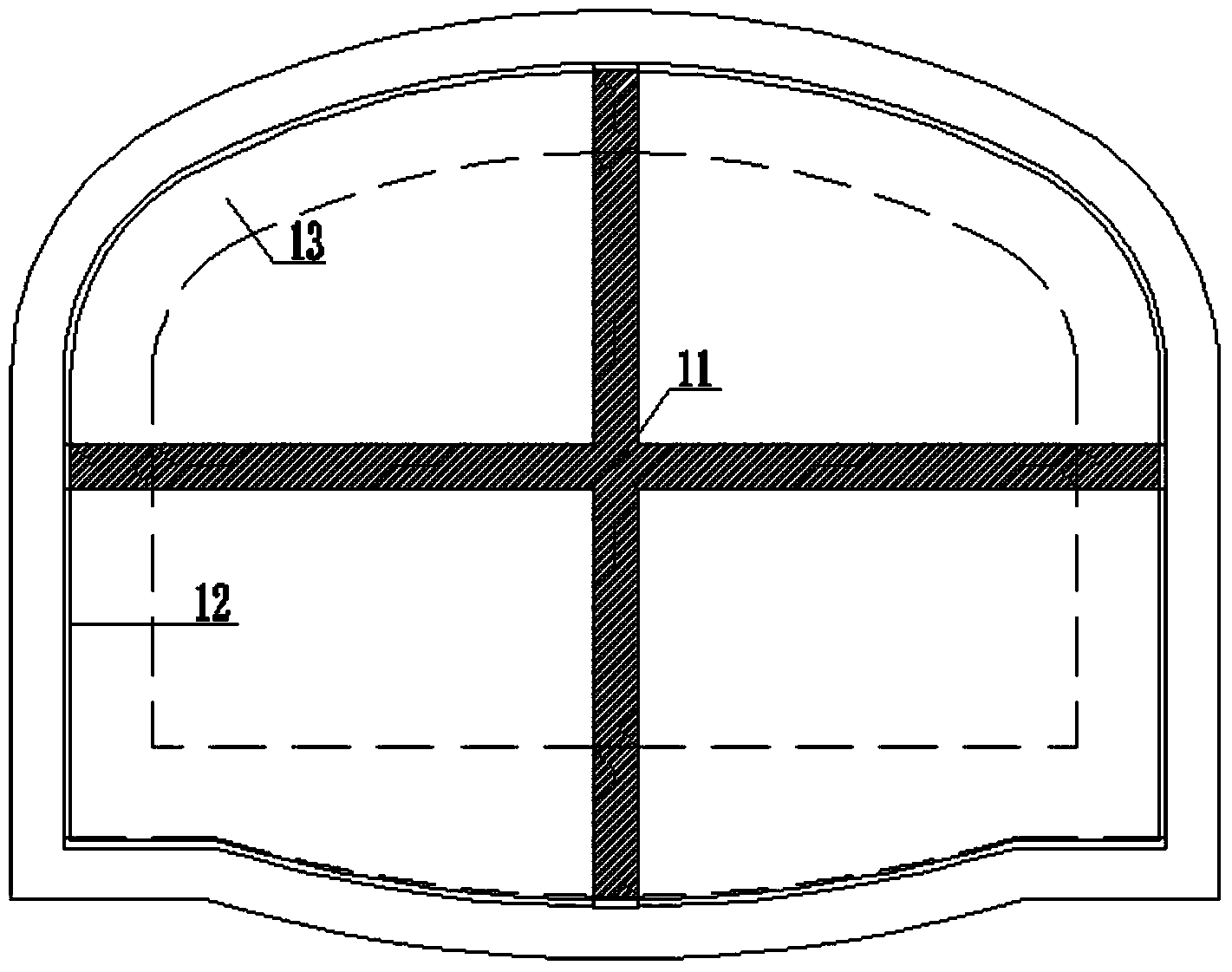

[0021] Such as figure 1 , 3 , Shown in 5: a kind of CRD construction method tunnel waterproof construction method, comprises the following steps:

[0022] ① After the initial support system is stabilized, deformation monitoring points shall be arranged on the vault and side walls to monitor the settlement deformation during construction;

[0023] ② After the concrete of the middle partition within the scope of the lining floor is broken, the I-beam 1 of the middle partition is removed by removing one by one;

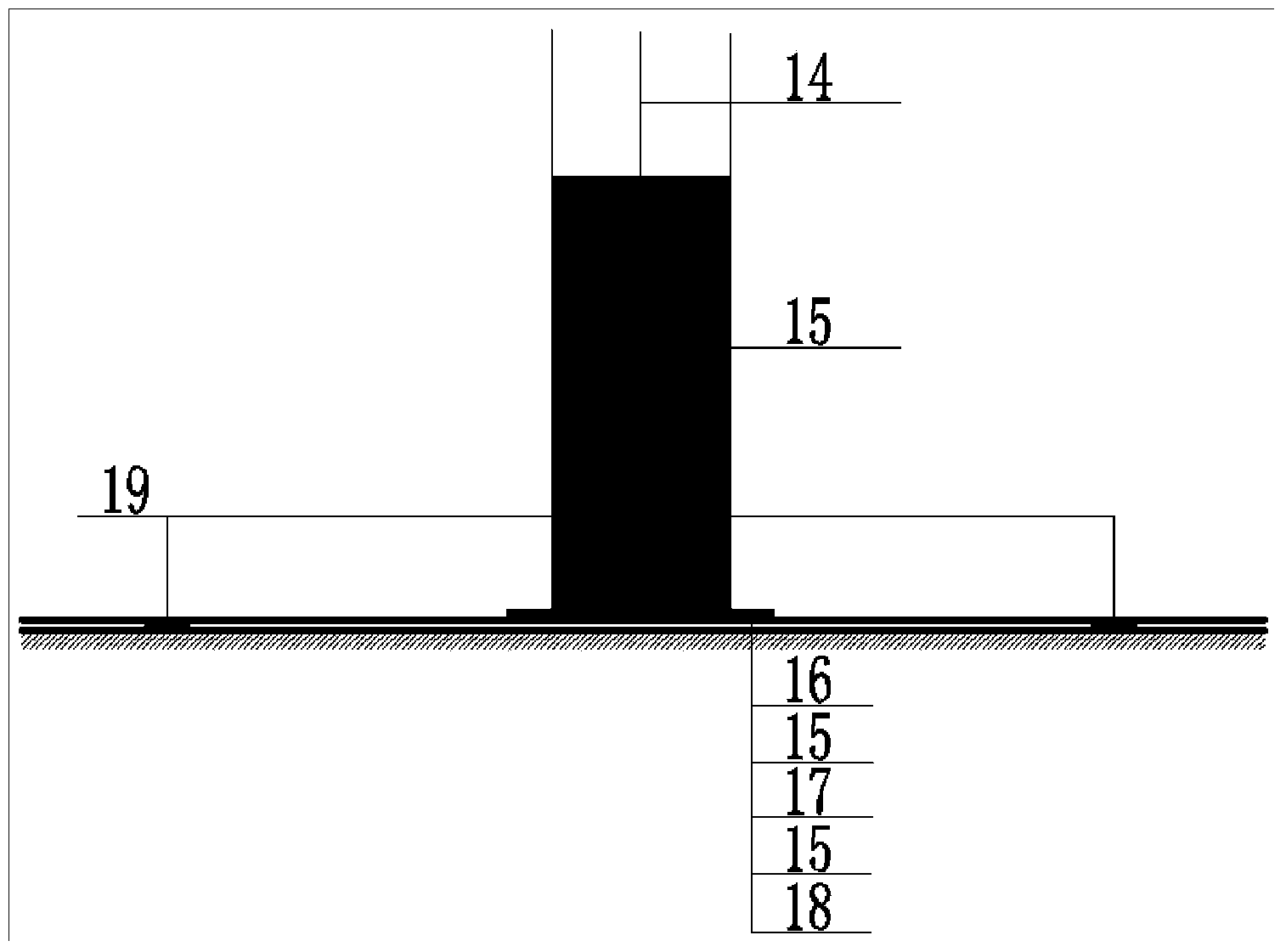

[0024] ③Grind the remaining I-beams that have not been removed, and smooth and harden them with cement mortar within 500mm around the I-beams to form a hardened base surface 18, ensuring that the I-beams and hardened base surfaces are smooth and free of residue, dry and water-free;

[0025] ④Apply rubberized asphalt 15 on the unremoved I-beam 10 and the hardened base surface, lay waterproof board 17 on the asphalt and paste it tightly with rubberized asphalt, and weld...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com