Joint reinforcement structure for shield tunnel end and a construction method

A technology for strengthening structures and shield tunnels, which is used in tunnels, tunnel linings, earthwork drilling, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

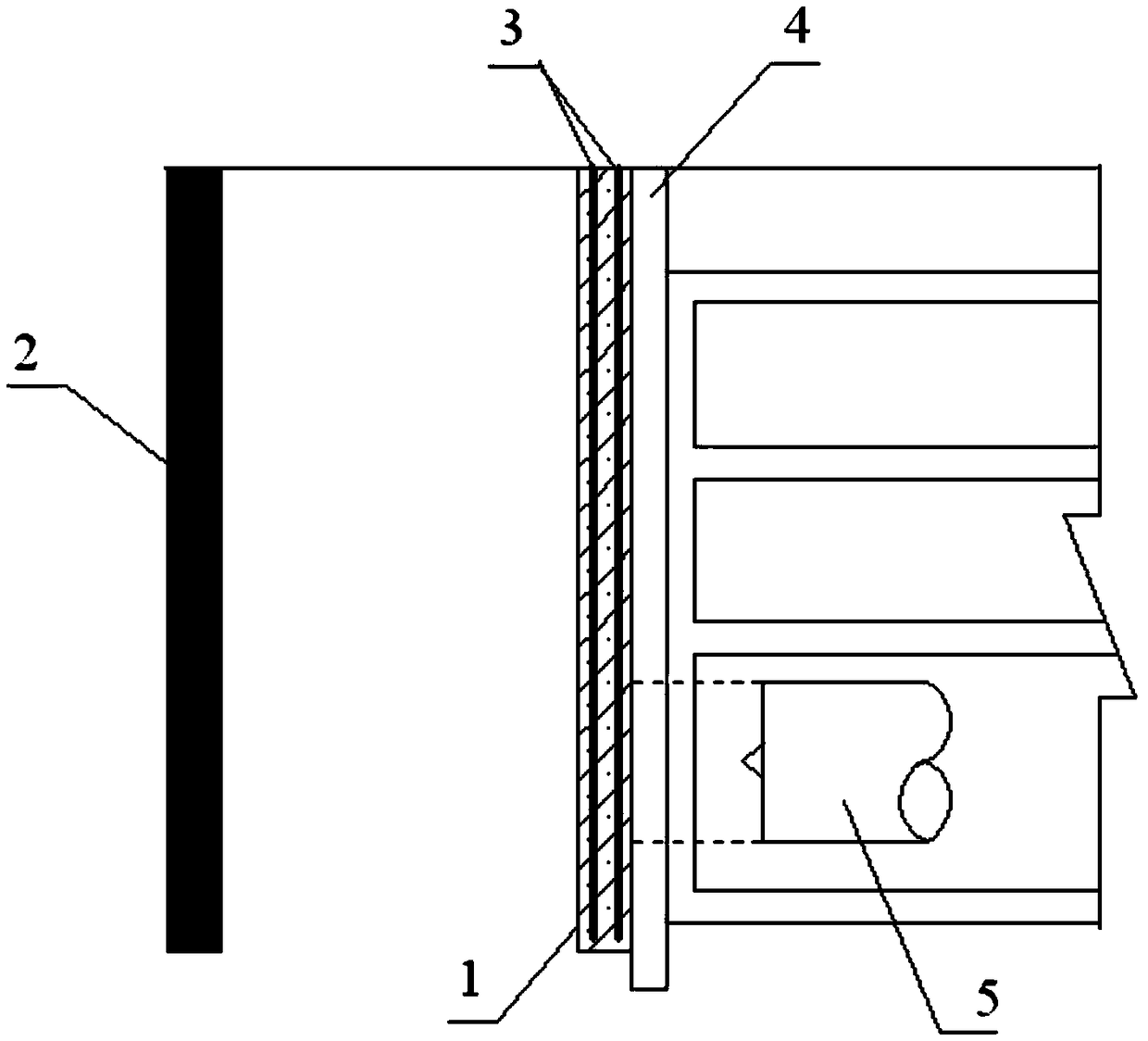

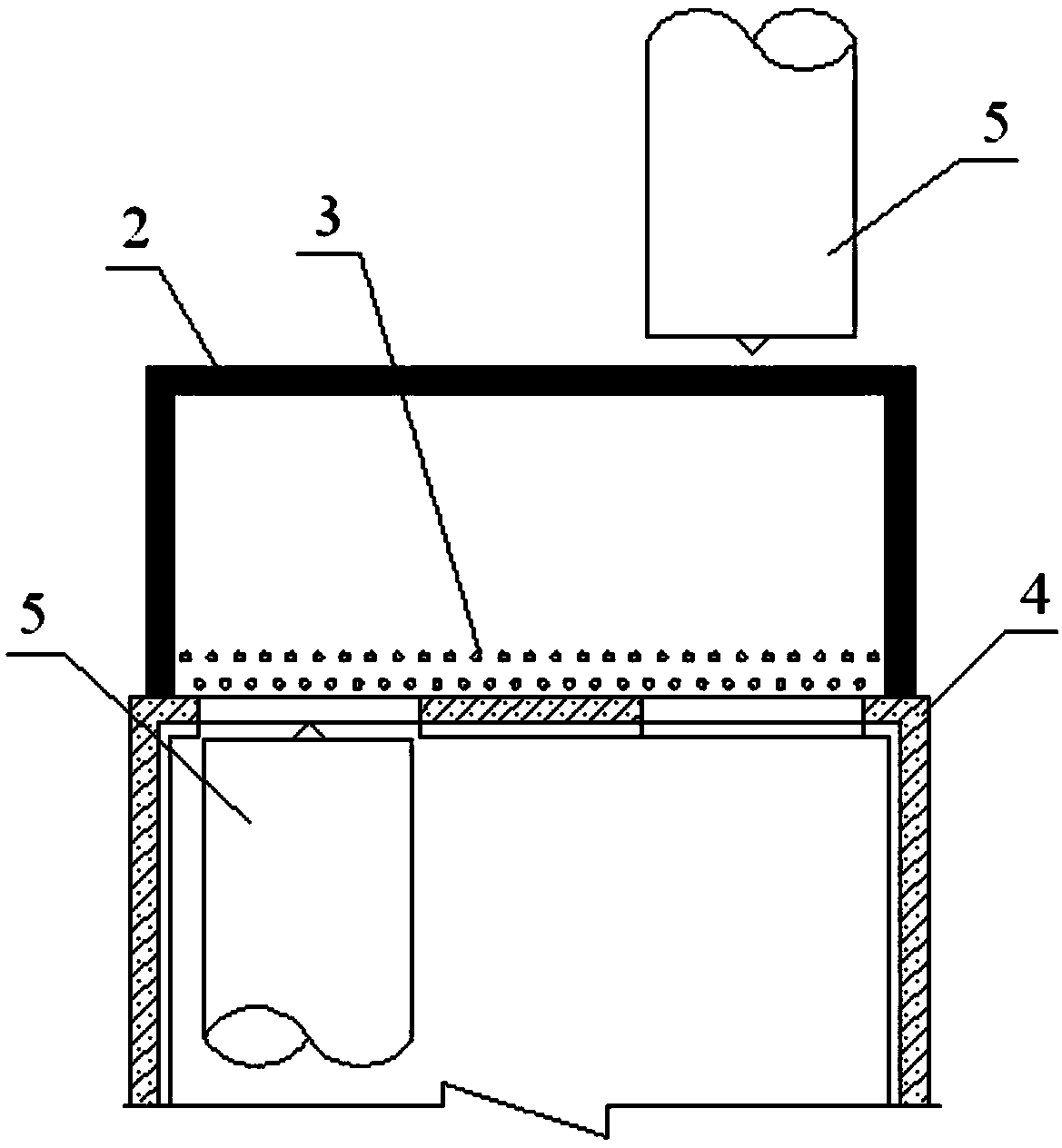

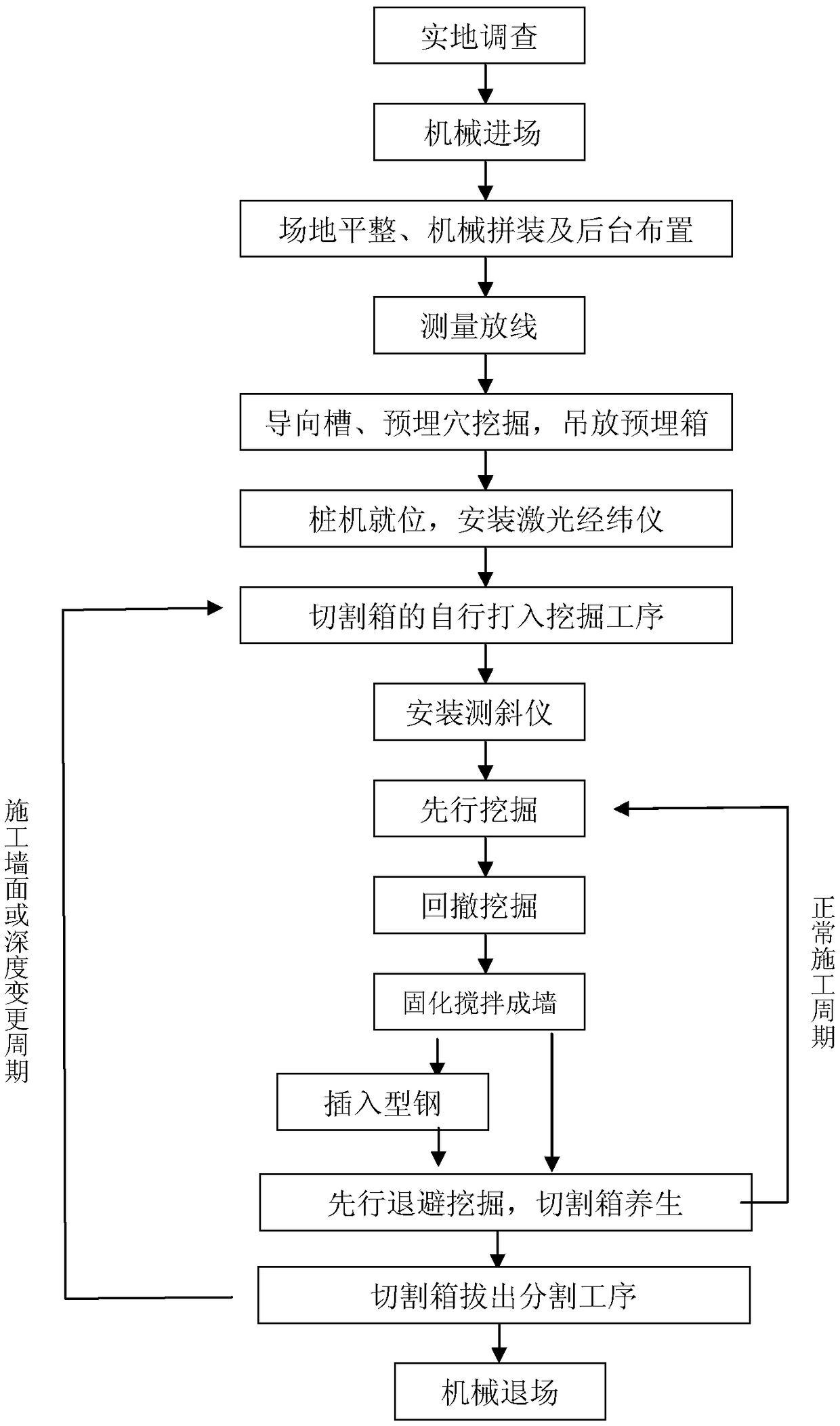

[0157] see Figure 1 to Figure 5 Shown:

[0158] The combined reinforcement structure at the end of the shield tunnel provided by the present invention is a rectangular box-type structure as a whole, and the rectangular box-type structure is surrounded by reinforcement structures on four sides, wherein the reinforcement structure near the foundation pit is frozen soil wall 1, and the other three sides The reinforced structure is cement-soil diaphragm wall 2.

[0159] The insertion depth of the vertical freezing pipe 3 in the permafrost wall 1 is 1-2m in the impermeable layer below, the layout length of the vertical freezing pipe 3 is 3m on both sides of the shield tunnel, and the diameter of the vertical freezing pipe 3 is 127mm or 108mm or 169mm; The freezing pipes 3 are arranged in 1-3 rows, arranged in flower arrangement, the spacing of the vertical freezing pipes 3 is 800mm, the vertical freezing pipes 3 close to the working well enclosure structure 4 are 300-400mm away f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com