Shield tail brush replacement annular freezing reinforcing water seal structure and construction method thereof

A shield tail brush and ring-shaped technology, which is applied in earthwork drilling, wellbore lining, tunnel lining, etc., can solve the problem of poor continuity of grouting curtain, lack of flexibility and toughness of grouting soil, shield tunnel and segment, shield tail brush Damage and other problems, to achieve the effect of perfect emergency plan and flexible and diverse punching forms

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0077] The present invention is described below in conjunction with accompanying drawing.

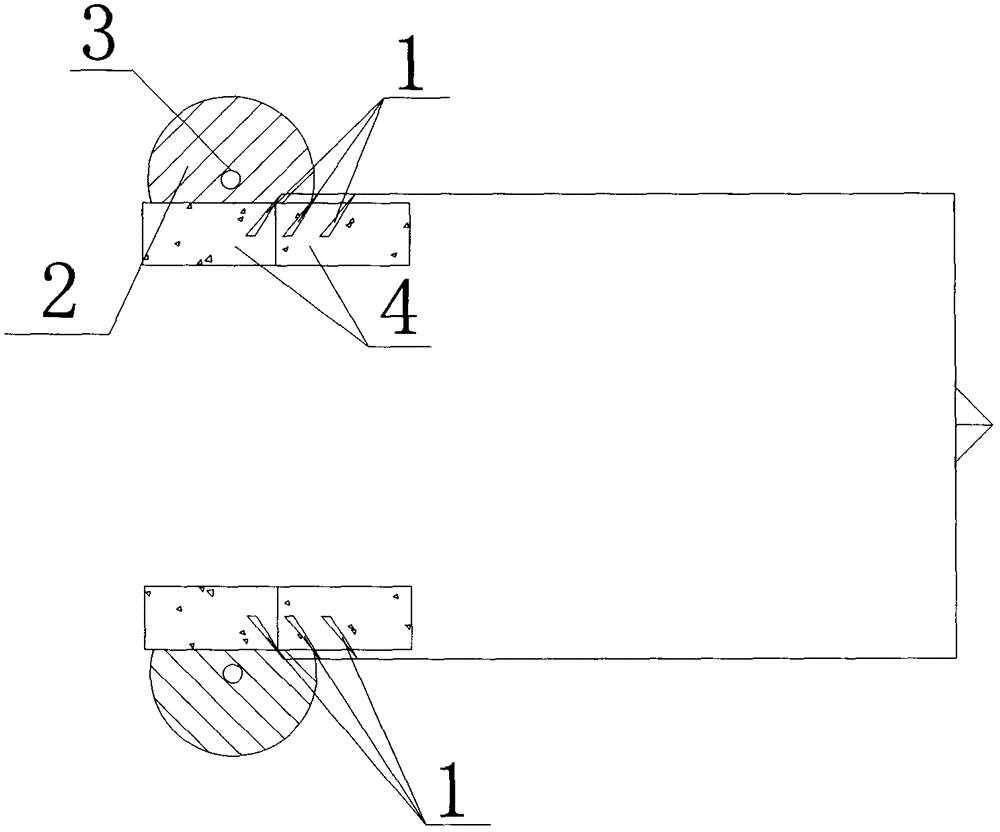

[0078] as attached figure 1 The shown annular freezing reinforced water-stop structure of the present invention when the shield tail brush is replaced is to use the annular freezing pipe construction equipment to bury 1 to 2 annular freezing pipes 3 in the soil 2 where the shield tail brush 1 needs to be replaced, and then use The artificial freezing method makes the soil 2 around the annular freezing pipe 3 form a temporary annular frozen soil curtain to reinforce the water-stop structure.

[0079] When the shield tail brush of the present invention is replaced, the construction technology and precautions of the ring-shaped frozen reinforced water-stop structure are as follows:

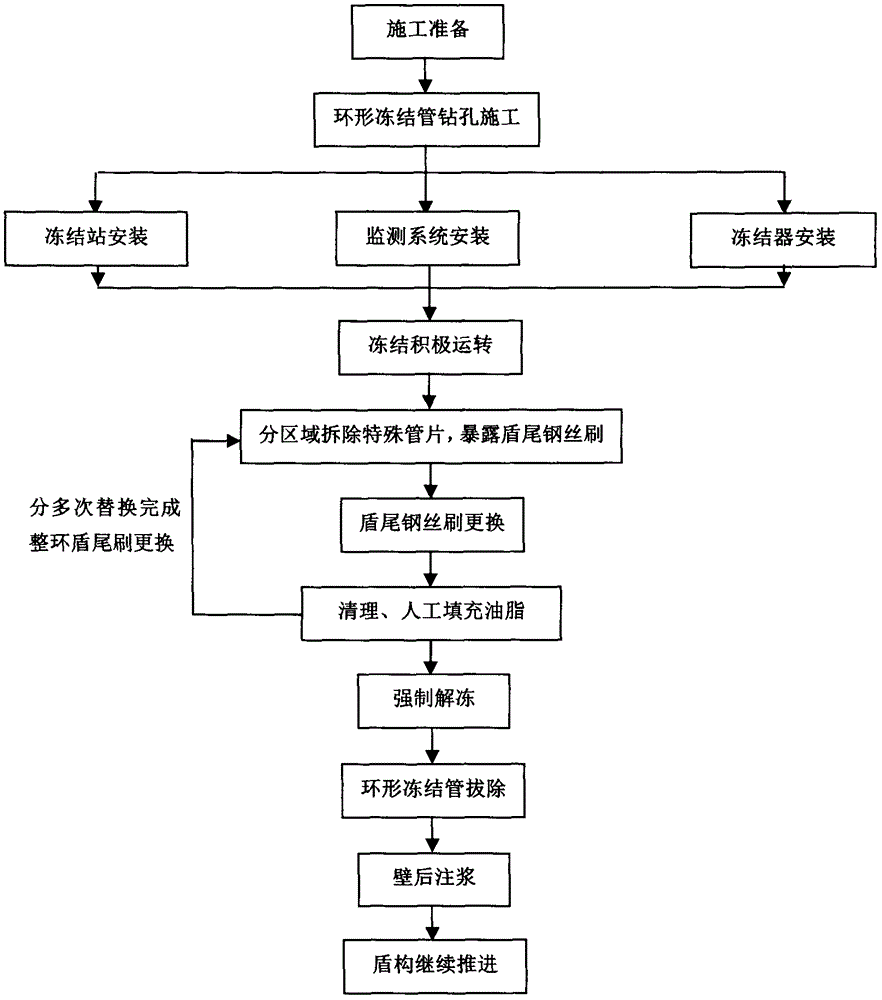

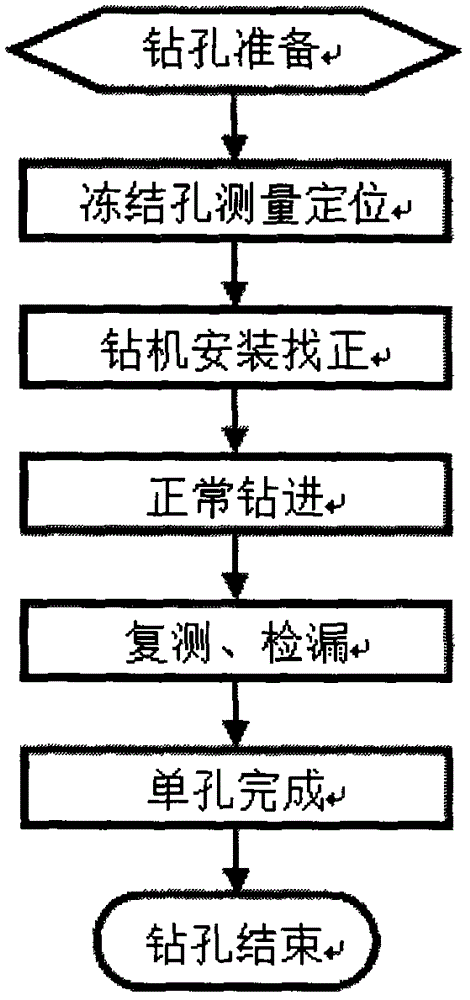

[0080] 1. Construction process

[0081] Construction preparation→Drilling construction of annular freezing pipe→Installation of freezing system and temperature measurement system→Active freezing (temperature...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com