Variable friction-type spherical surface-cylindrical surface friction-type support

A technology of variable friction and cylindrical surface, applied in the direction of bridge parts, building components, bridges, etc., can solve the problems of structural resonance, increase structural seismic response, etc., achieve the effect of simple structure, prolong service life, and protect from damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

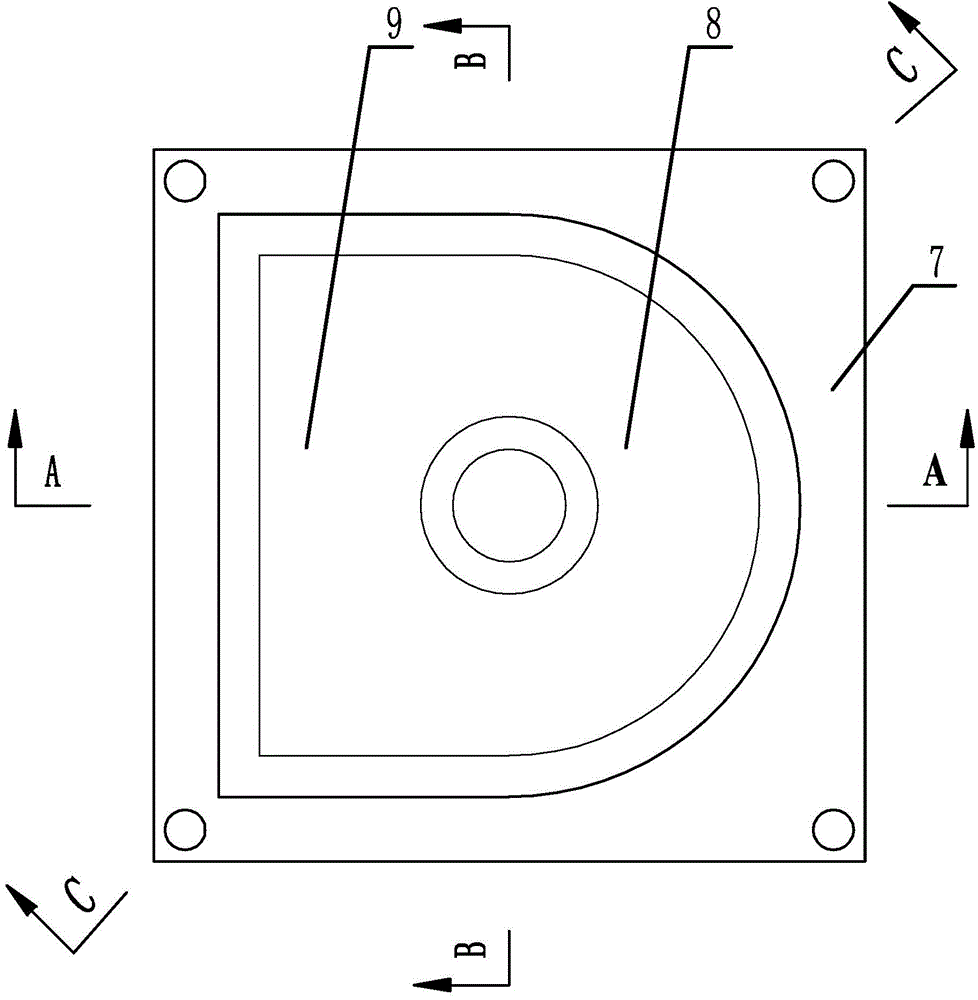

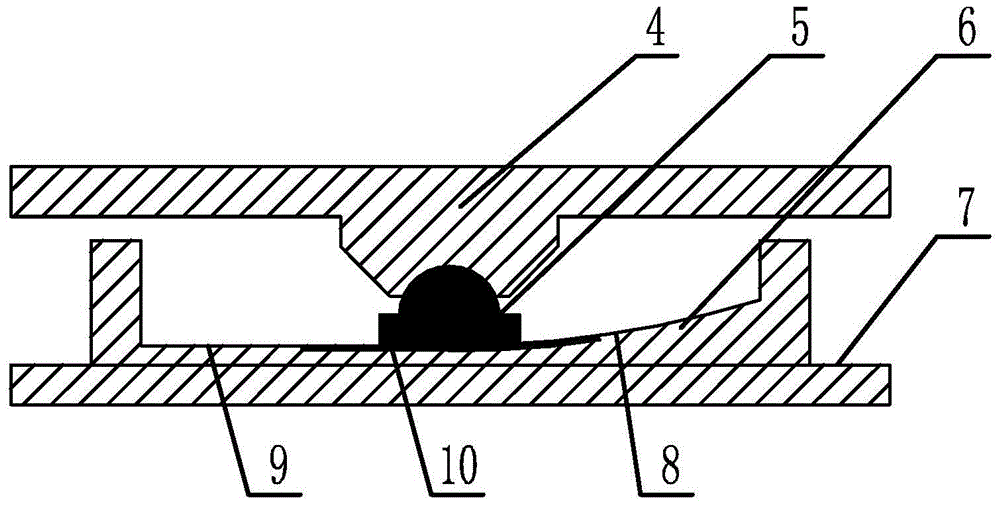

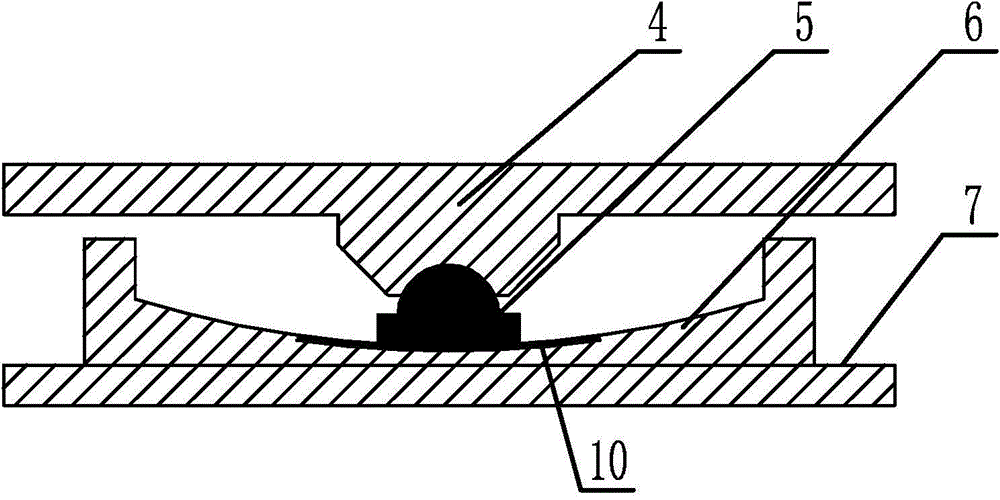

[0019] Specific implementation mode one: as Figure 1-8 As shown, the variable friction spherical-cylindrical friction bearing of this embodiment includes a cover plate 4, a slider 5, a chute 6 and a connecting steel plate 7, the chute 6 is installed on the upper end surface of the connecting steel plate 7, and the sliding block 5 is located in the chute 6, the upper half of the slider 5 is hemispherical, and the center of the lower end of the cover plate 4 is processed with a hemispherical groove matching the slider 5, and the cover plate 4 is supported on the chute 6 by the slider 5 On the upper end face of the chute, the outline of the left half of the chute 6 is rectangular, the outline of the right half of the chute is semicircular, the left half of the chute 6 is processed with a cylindrical groove 9, and the right half of the chute 6 Spherical groove 8 is processed on the inside, and the arc surface radius of cylindrical groove 9 is set the same as the arc surface radiu...

specific Embodiment approach 2

[0031] Specific implementation mode two: as Figure 2-8 As shown, the radius of curvature of the bottom surface of the slider 5 in this embodiment is consistent with the radius of curvature of the chute 6 . Such a design can make effective contact between the slider 5 and the chute 6, increase the effective friction of the friction pendulum support, improve the sliding energy dissipation capacity, and reduce the stress concentration of the chute 6, reduce collisions, reduce wear, and extend Support life. Other components and connections are the same as those in the first embodiment.

specific Embodiment approach 3

[0032] Specific implementation mode three: as Figure 2-8 As shown, the spherical radius of the upper hemisphere of the slider 5 in this embodiment is consistent with the radius of the hemispherical groove on the cover plate 4 . Such a design can make effective contact between the slider 5 and the hemispherical groove on the cover plate 4, increase the effective friction of the friction pendulum support, improve the sliding energy dissipation capacity, and reduce the friction of the hemispherical groove on the cover plate 4. Stress concentration reduces collision, reduces wear and prolongs the service life of the support. Other compositions and connections are the same as those in Embodiment 1 or 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com