Method for reinforcing circular pipe culvert by adopting HDPE winding reinforcing tubes and cement mortar

A technology of winding reinforced pipes and cement mortar, which is applied in the repair of basic structures, road floors, buildings, etc., can solve the problems of affecting the normal traffic of roads, lack of repair methods, and difficult construction, etc., to achieve good construction quality and light weight , Good assembly performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

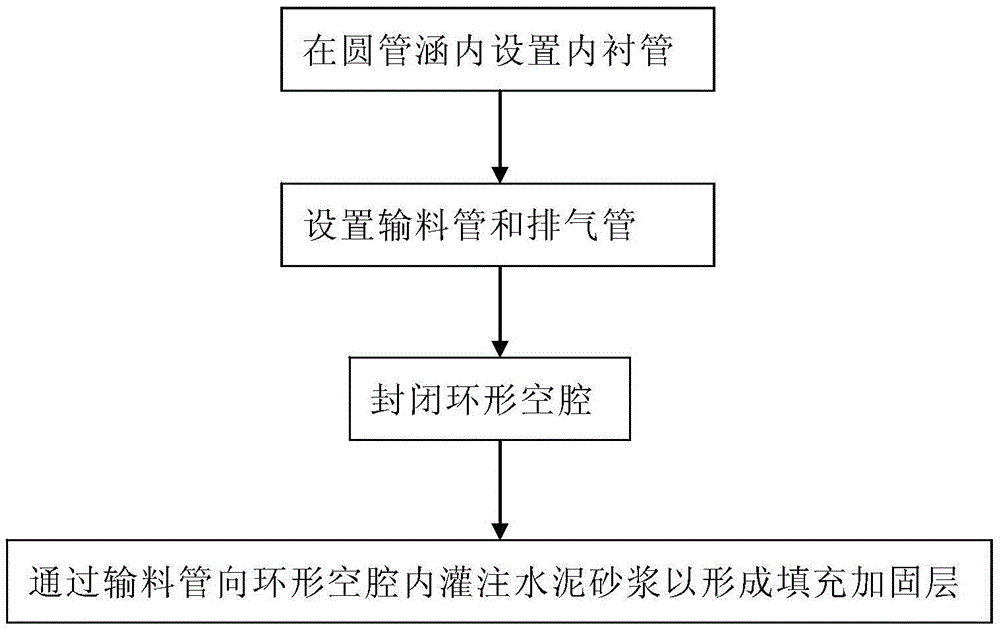

[0040] Such as Figure 1 to Figure 5 Shown is a method for reinforcing circular pipe culverts with HDPE winding reinforcement pipes and cement mortar, comprising the following steps:

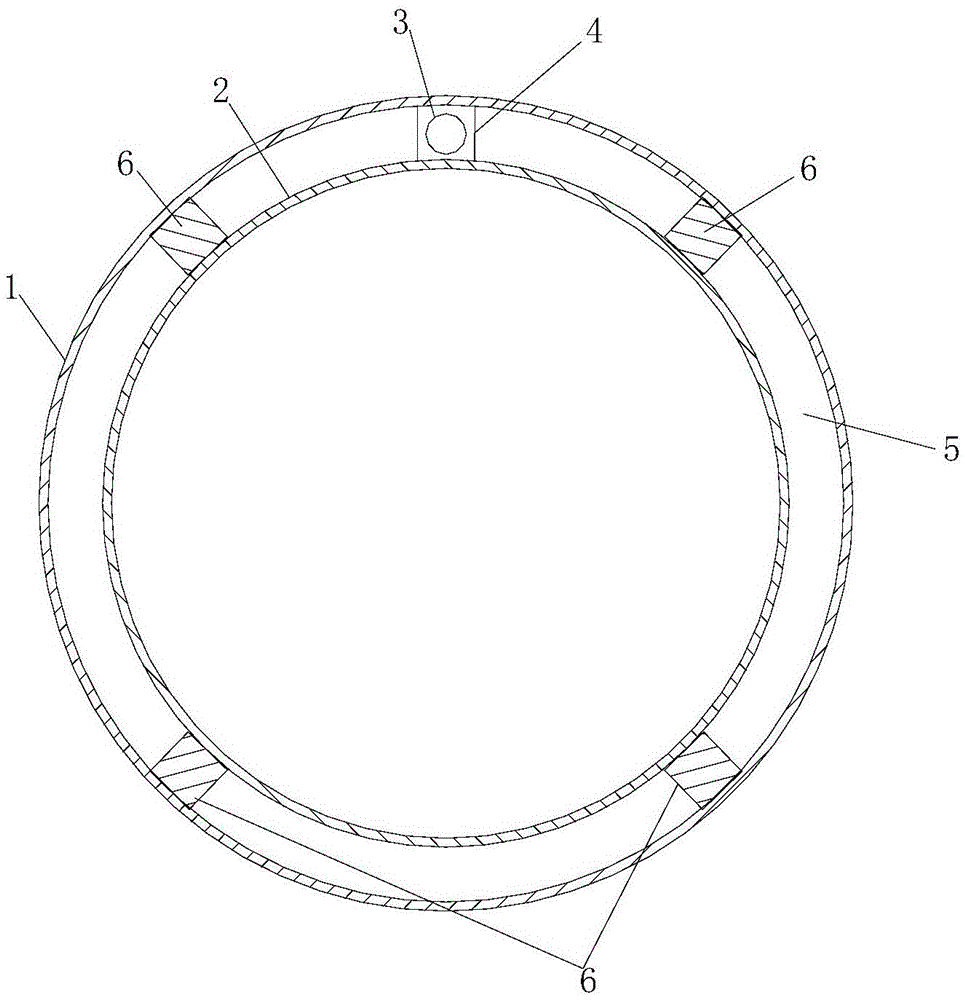

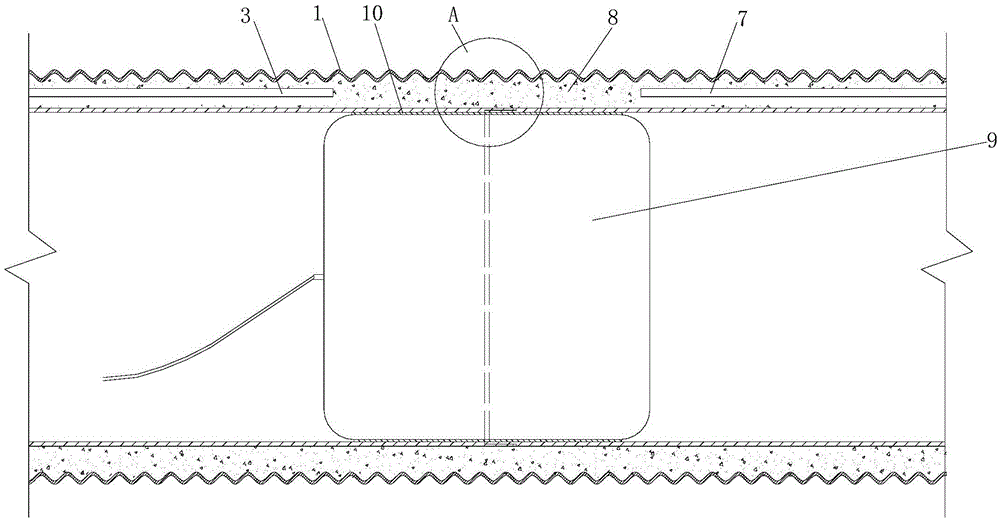

[0041] Step 1. Set the inner liner 2 in the round pipe culvert 1: connect multiple HDPE winding reinforcement pipes 2-1 in sequence and move them into the round pipe culvert 1 to form the inner liner 2, and the inner liner 2 and the round pipe An annular cavity 5 is formed between the culverts 1;

[0042] Step 2, setting of the feeding pipe 3 and the exhaust pipe 7: extending the feeding pipe 3 and the exhaust pipe 7 into the annular cavity 5;

[0043]Step 3, closing the annular cavity 5: building a first plugging end wall 11 for closing one end of the annular cavity 5 at the water inlet of the circular pipe culvert 1, The water outlet masonry is used to seal the second end wall 12 of the other end of the annular cavity 5, and the first end wall 11 and the second end wall 12 are provided with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com