Embedded type shaft excavation construction technology

A construction technology, embedded technology, applied in shaft equipment, well sinking, mining equipment and other directions, can solve the problem of no large-scale application, and achieve the effect of convenient control, strong adaptability, and shortened construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

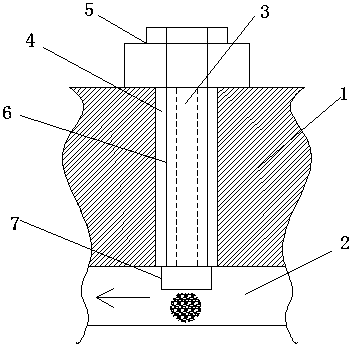

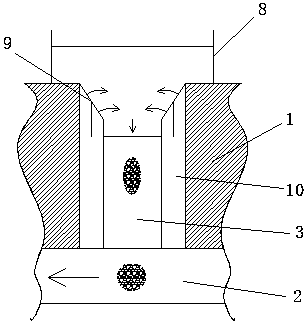

[0035] Such as figure 1 with 2 As shown, an embedded shaft excavation construction technology, the specific steps are as follows:

[0036] S1. Pilot tunnel construction:

[0037] S1-1. Excavating a horizontal tunnel 2 at the bottom of the proposed shaft 10;

[0038] S1-2. Before the construction of the vertical shaft starts, stake out the center of the proposed vertical shaft 10 on the ground 1 at the top of the proposed vertical shaft 10 with a total station, and use the down-the-hole drill to drill a vertical hole with a diameter of 110mm at the center of the proposed shaft. The pilot hole 3, the bottom of the pilot hole 3 is connected with the horizontal tunnel 2. When drilling, adjust the position of the down-the-hole drilling rig to ensure that the hole deviation is within 10cm. After the position of the pilot hole 3 is checked and correct, vertical Drill two holes with a diameter of 110mm as the hoisting basket hoisting rope hole 4, the bottom of the hoisting basket h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com