Prefabricated pipe joint assembly equipment and construction method thereof

A technology for hoisting equipment and pipe joints, which is applied in artificial islands, water conservancy projects, infrastructure projects, etc., can solve the problems of bracing, alignment, tensioning, and large impact on the exhaust gas environment without prefabricated pipe joints, and is beneficial to Green and civilized construction management, improved assembly efficiency, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

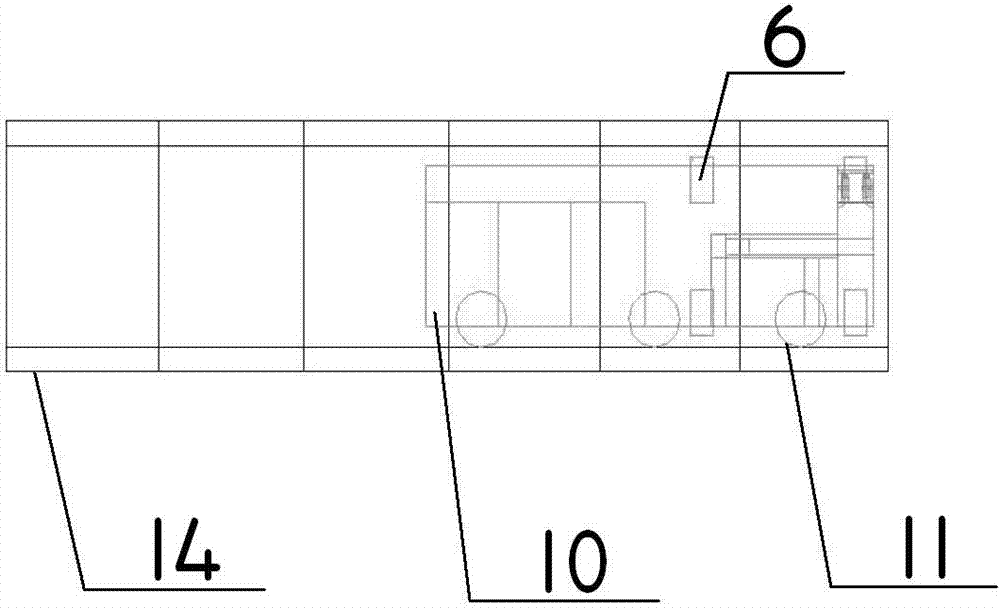

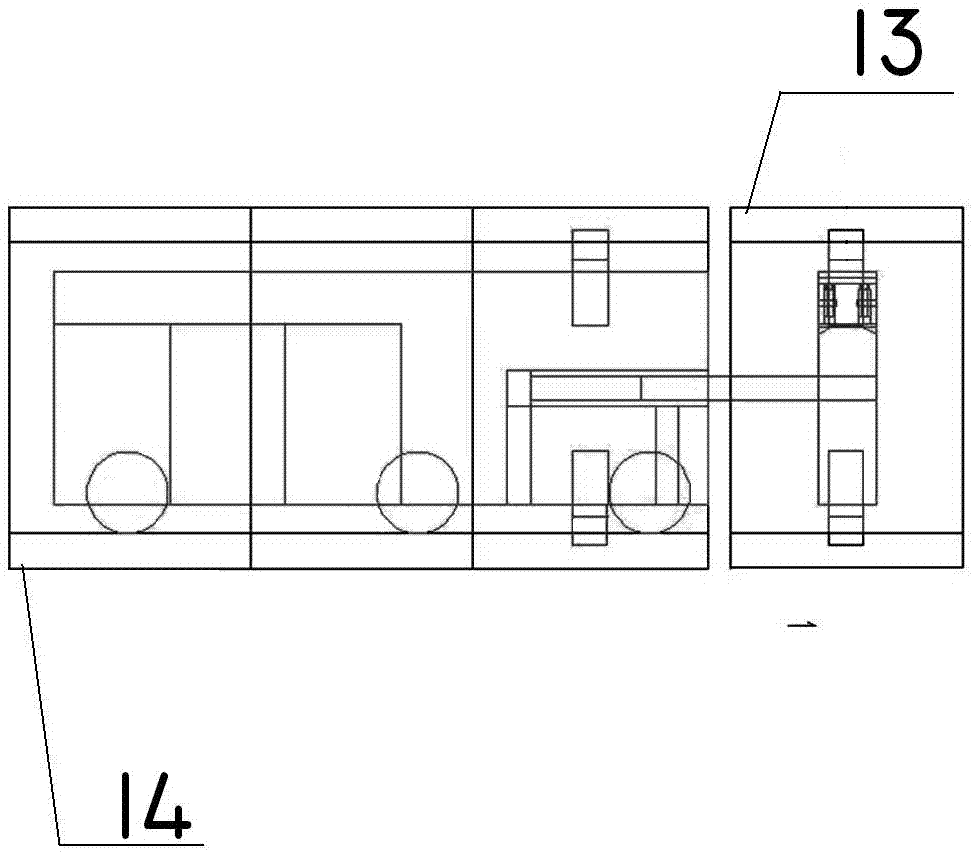

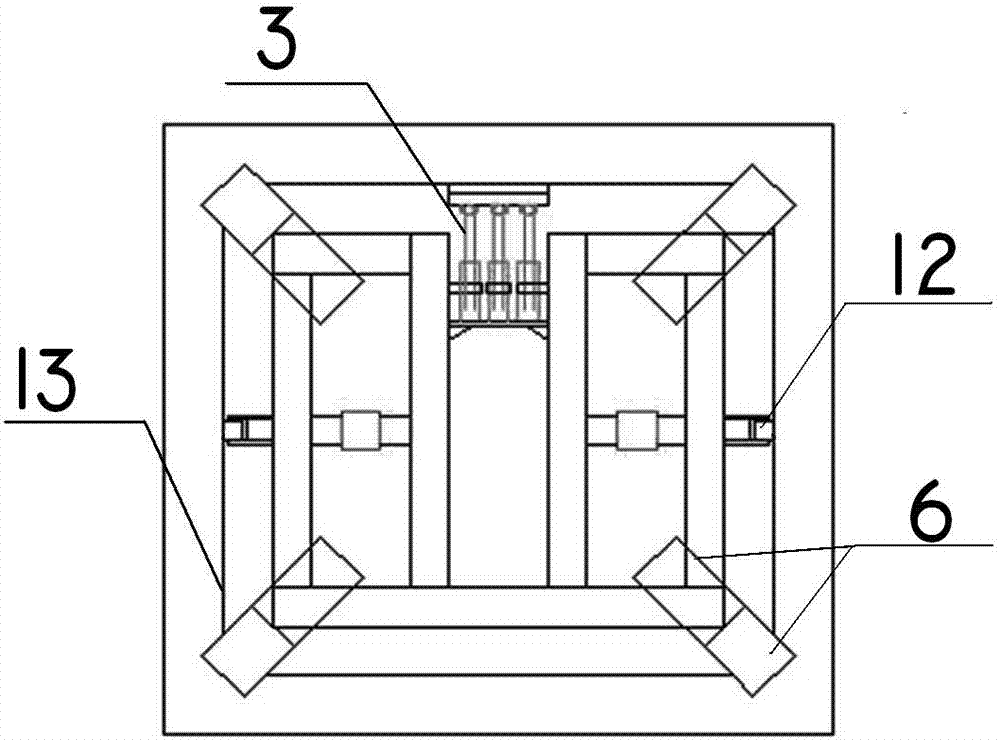

[0046] Based on the above-mentioned embodiments, the present invention provides a prefabricated pipe joint 13 assembling equipment and its construction method, which provide the possibility for the prefabricated pipe joint 13 to be braced, aligned, aligned, tightened, and formed at one time.

[0047] The present invention can realize the one-time molding and assembling process of the prefabricated integrated pipe gallery 14, including steps such as bracing, alignment adjustment and tensioning of the prefabricated pipe joints 13. Specifically, the present invention provides a prefabricated pipe joint 13 assembling equipment, including a bracing mechanism, a positioning mechanism 4 , a tensioning mechanism and a power system 10 .

[0048] Such as Figure 4 As shown, the brace mechanism includes a lifting device 1 and a brace frame 2, the lift device 1 is composed of a lifting cylinder 3 and a steel pallet, and the lift device 1 is arranged on the brace frame 2 near the tail of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com