Fireproof lightweight composite thermal insulation mortar and its preparation method

A composite thermal insulation mortar and lightweight technology, applied in the field of wall materials, can solve the problems of high cost, low compressive strength, poor safety and stability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0009] Example 1: First add 1kg of wood fiber, 6Kg of hydroxypropyl methyl fiber, and 3kg of polypropylene short fiber into the powder mixer, start the mixer at normal temperature and pressure, and stir for 3-5min at a speed of 50r / min, then add 600Kg of cement , fly ash 120Kg, heavy calcium powder 80Kg, slaked lime 75Kg, stir for 25-30min, after mixing evenly, add vitrified microbeads 300Kg, resin type redispersible rubber powder 5.5Kg, thixotropic lubricant 1Kg, high-efficiency water reducing Waterproofing agent 1Kg, concrete waterproofing agent 3Kg, air-entraining agent 0.1Kg, continue to stir for 30-35min, fully mix evenly, and obtain the powdery product.

Embodiment 2

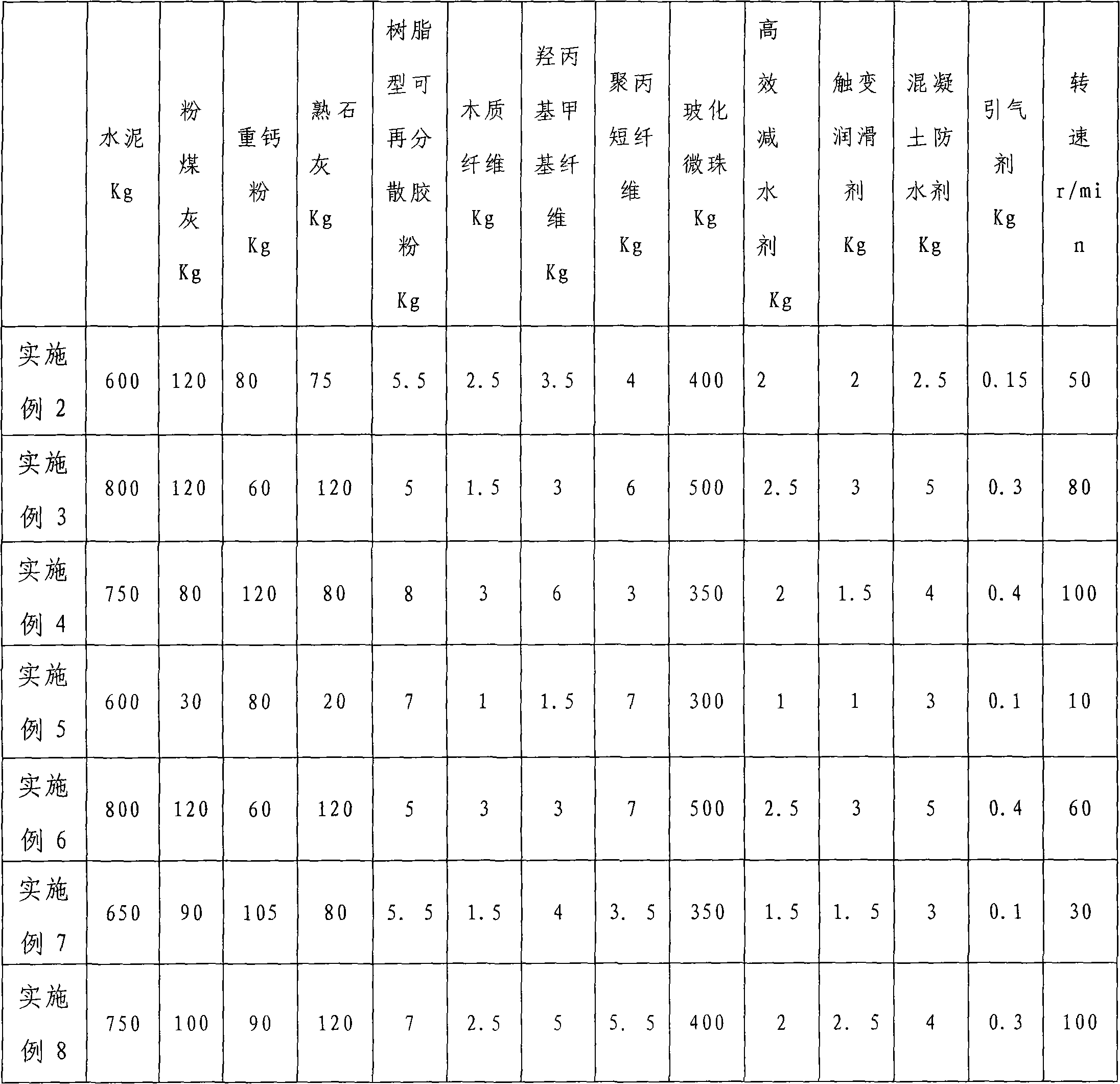

[0010] Embodiment 2: The dosage of each component and the stirring speed are as follows, and all the other operations are the same as in Embodiment 1.

[0011]

[0012] The thermal insulation mortar of the present invention is through testing, and main index is as follows:

[0013] Appearance: gray powder; bulk density: 341Kg / m 3 ; Compressive strength: 1.05Mpa; thermal conductivity: 0.071W / (m.k); linear shrinkage: 0.20%; compressive shear bond strength: 166Kpa; combustion performance level: A. How to use: Add water and stir to a proper consistency under normal temperature and pressure, and use it on the wall.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com