Processing method for antibiotics bacterial slag containing zinc

A technology of antibiotic slag and treatment method, applied in the direction of separation method, water/sewage treatment, chemical instrument and method, etc., can solve the problems of waste slag pollution, inability to comprehensively utilize, pollution of environment by zinc-containing antibiotic slag, and achieve Effects of solving pollution problems and reducing toxicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Treatment of erythromycin residue

[0024] 1.1 Bacterial residues to remove zinc ions Weigh 10kg of erythromycin residues, add 70kg of water, fully suspend, take a little as a reference, and adjust the pH to 5.0 with 6N HCl for the rest, add the acid-treated bacterial residue suspension Hangzhou Zhengguang Resin Co., Ltd. produced 20kg of D850 chelating resin, stirred for 5 minutes, and filtered the suspension with a 400-mesh screen to separate the resin from the fungus residue, and the resin was retained. Take a little treated fungus residue suspension as a sample and the above reference substance for the following inspection:

[0025] 1.2 Inspection

[0026] (1) Filter the above untreated erythromycin residue reference substance with filter paper to obtain a supernatant, adjust the pH to alkaline with NaOH, and then obvious precipitation occurs. Continuing to add lye can make the precipitate disappear, which shows that Zn(OH) is formed under weakly alkaline conditio...

Embodiment 2

[0031] Treatment of zinc-containing antibiotic residues:

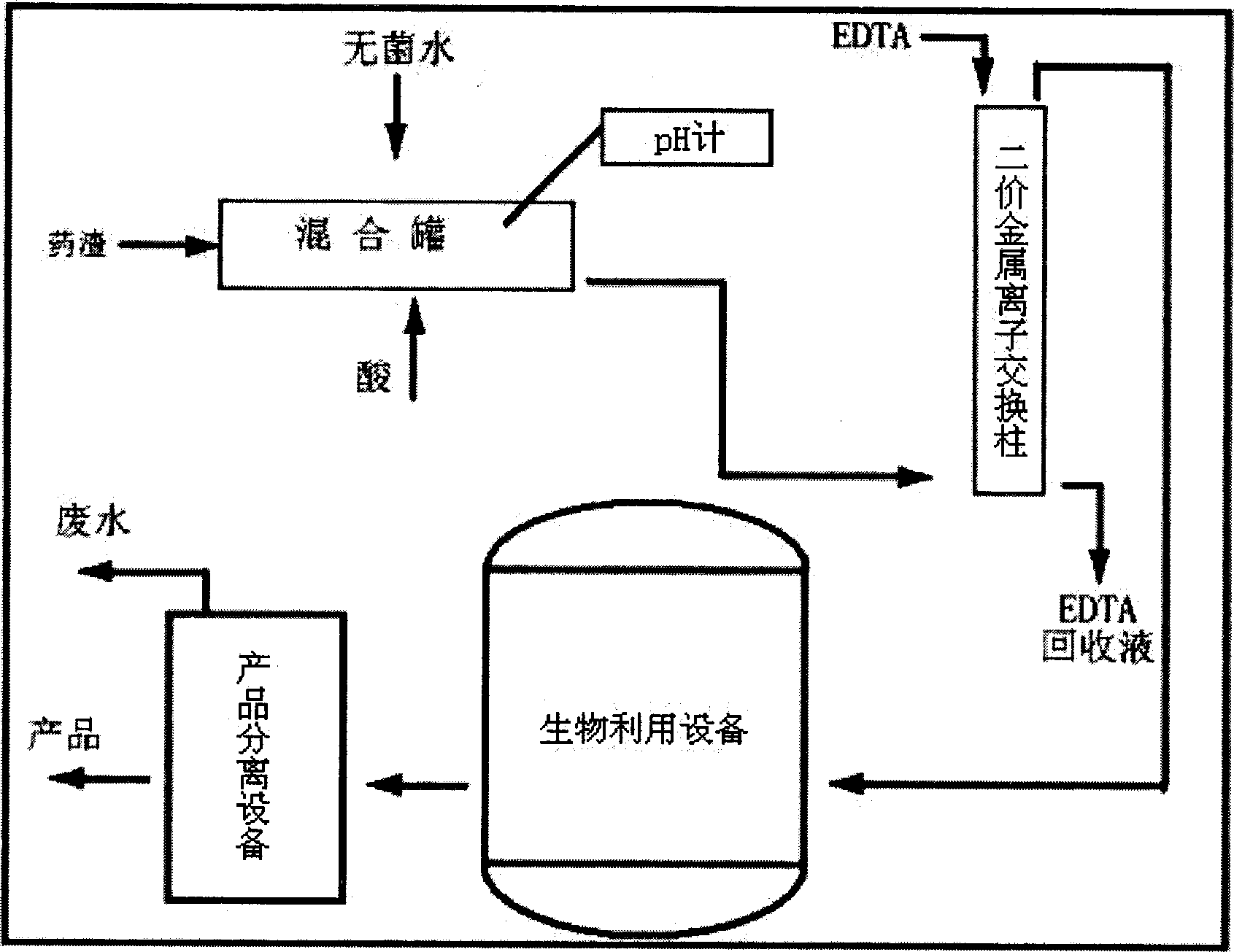

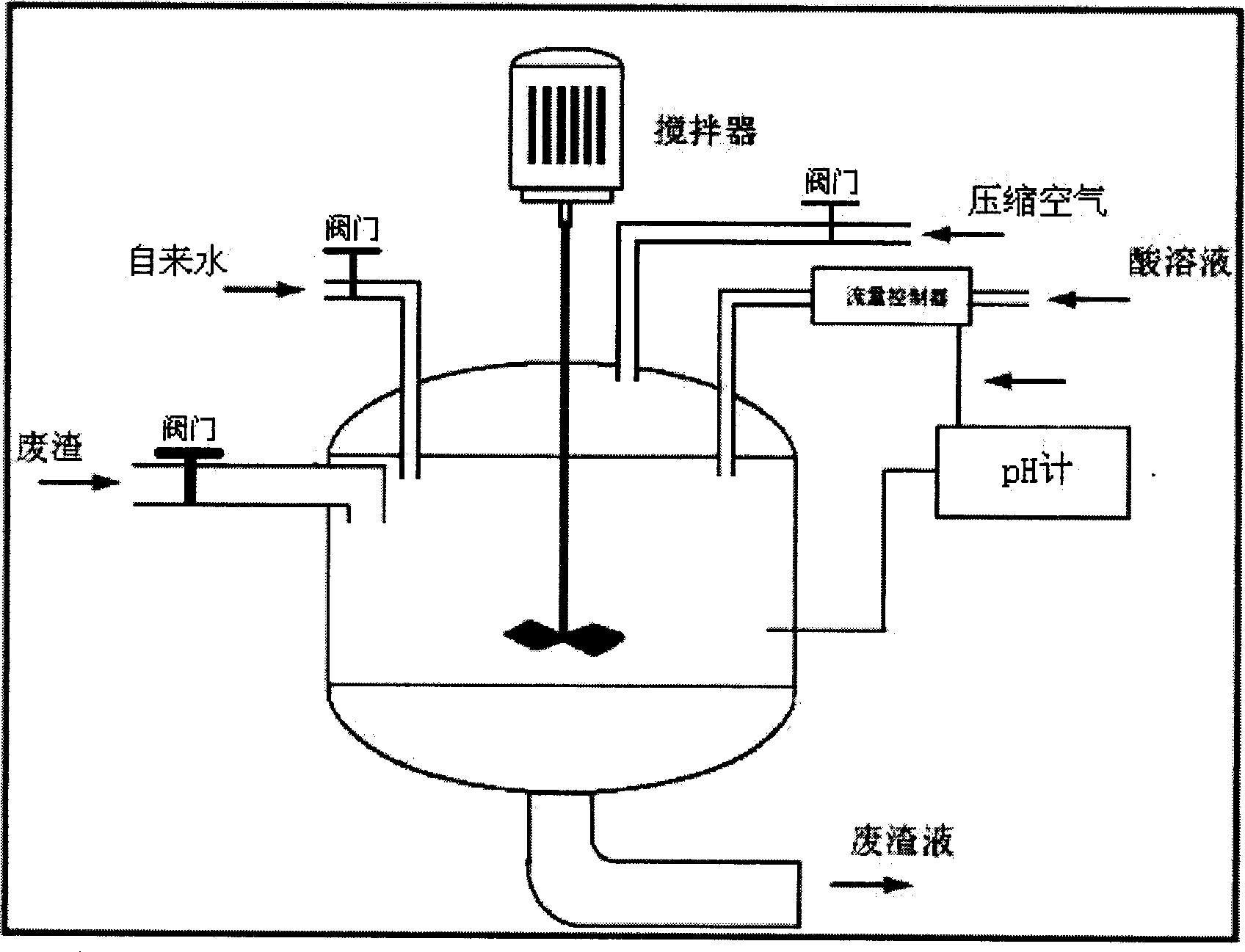

[0032] a. Add 5 kg of zinc-containing erythrotoxin antibiotic slag and 40 kg of tap water in the mixing tank with a weight ratio of 1:8, stir to make it fully suspended; feed 4N sulfuric acid to continue stirring, and adjust the pH to 5;

[0033] B. Feed compressed air into the mixing tank to make the bacterium residue suspension flow through from bottom to top. In the metal ion adsorption column, the dezincified bacteria residue suspension is obtained from the upper end of the adsorption column;

[0034] Inspection: Take a little suspension of the above-mentioned processed fungus residue, filter it with filter paper to obtain the supernatant, adjust the pH to 8 with NaOH, and no precipitation occurs.

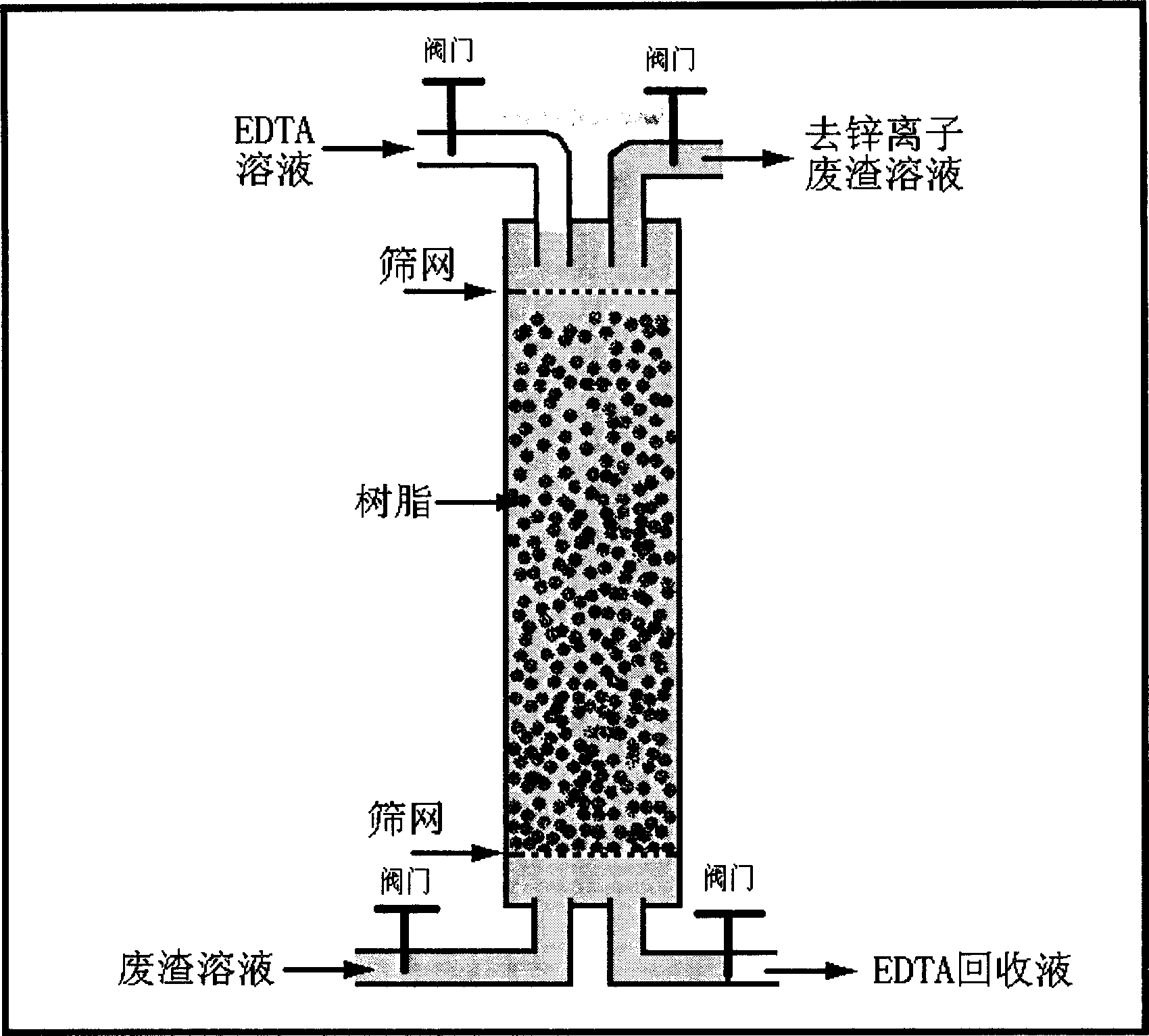

[0035] c. Pass the used divalent metal ion adsorption column into the divalent metal ion adsorption column from top to bottom with 120mM sodium ethylenediamine tetraacetate solution to regenerate the medium in the diva...

Embodiment 3

[0037] Treatment of zinc-containing antibiotic residues:

[0038] a. Add 10kg of erythromycin zinc-containing antibiotic bacteria residue with a weight ratio of 1:5 and 50kg of tap water into the mixing tank, stir to make it fully suspended; feed 5N acetic acid to continue stirring, and adjust the pH to 4;

[0039]B. Feed compressed air into the mixing tank to make the bacterium residue suspension flow through from bottom to top. In the metal ion adsorption column, the dezincified bacteria residue suspension is obtained from the upper end of the adsorption column;

[0040] Inspection: Take a little suspension of the above-mentioned processed fungus residue, filter it with filter paper to obtain the supernatant, adjust the pH to 8 with NaOH, and no precipitation occurs.

[0041] c. Pass the used divalent metal ion adsorption column into the divalent metal ion adsorption column from top to bottom with 120mM sodium ethylenediamine tetraacetate solution to regenerate the medium i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com