Method for microwave synthesis of nano-ZnO assembled cotton fibers

A microwave synthesis, cotton fiber technology, applied in fiber processing, textile and papermaking, physical processing and other directions, can solve the problems of toxicity, upper respiratory tract irritation, high cost, and achieve the effect of broadening the application field

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

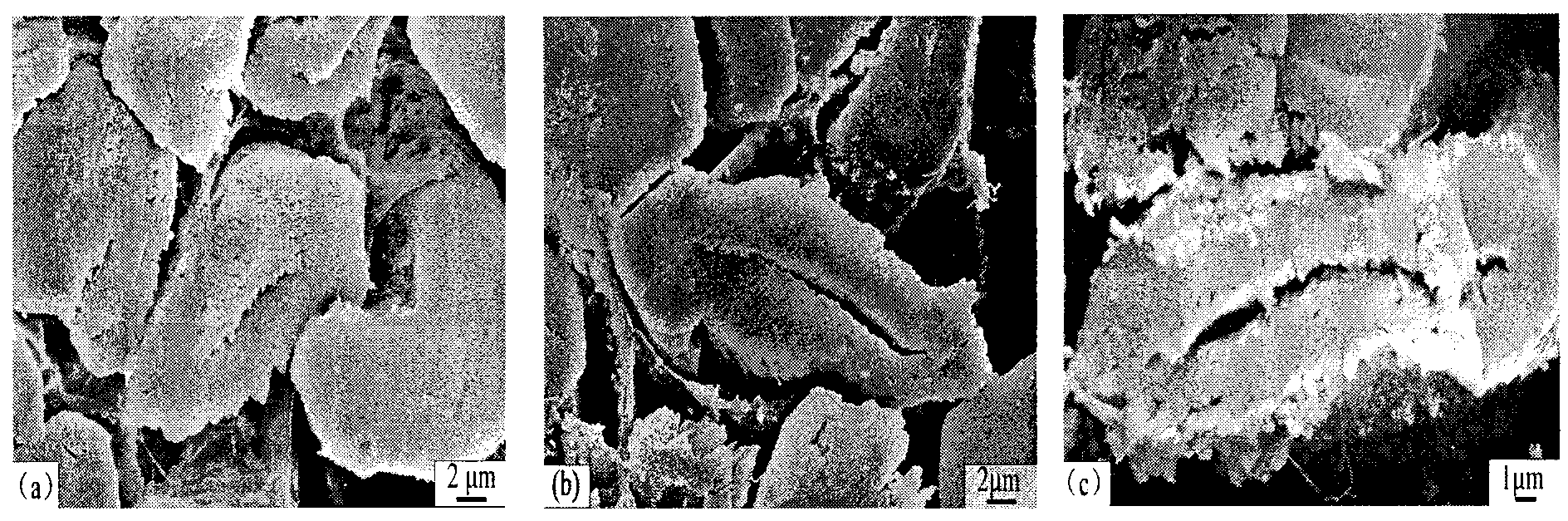

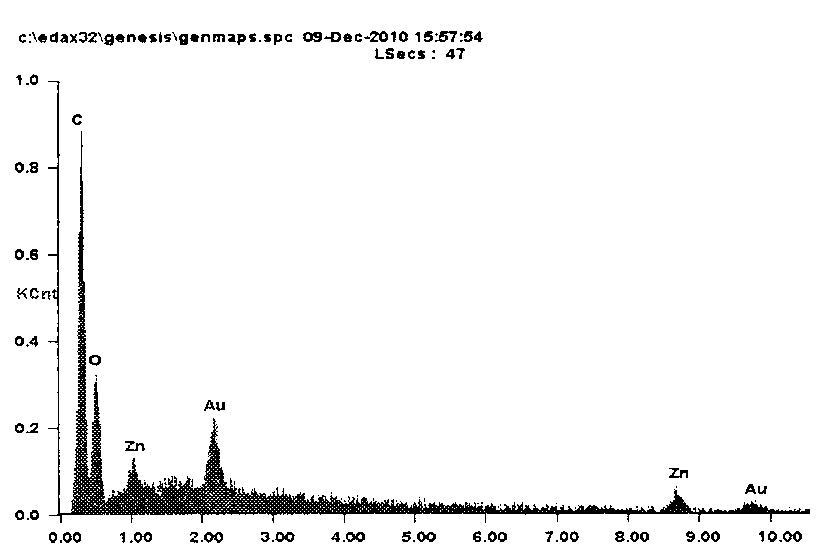

Image

Examples

Embodiment 1

[0019] (1) Preparation of zinc ammonia solution

[0020] Take the same volume of NaOH solution and zinc nitrate solution, slowly add the NaOH solution into the zinc nitrate solution, stir continuously, obtain a precipitate, vacuum filter, clean to obtain a pure zinc hydroxide precipitate, transfer the precipitate to a beaker, add dropwise 25 % ammoniacal liquor until the precipitation is completely dissolved, and the solution is clarified, and the solution is suction-filtered to obtain a zinc-ammonia solution, and the concentration of the reaction liquid substance is about 0.05mol / l.

[0021] (2) Microwave synthesis samples

[0022] Take the reaction solution in (1), add hexadecyltrimethylammonium bromide and tributyl phosphate in turn, stir evenly, put natural cotton into it, and treat it under microwave power 296w for 5 minutes until the natural cotton is transparently dispersed ; wherein the mass ratio of zinc nitrate, cetyltrimethylammonium bromide, tributyl phosphate and...

Embodiment 2

[0026] (1) Preparation of zinc ammonia solution

[0027] Take the same volume of NaOH solution and zinc nitrate solution, slowly add the NaOH solution into the zinc nitrate solution, stir continuously, obtain a precipitate, vacuum filter, clean to obtain a pure zinc hydroxide precipitate, transfer the precipitate to a beaker, add dropwise 25 % ammoniacal liquor until the precipitation is completely dissolved, and the solution is clarified, and the solution is suction-filtered to obtain a zinc-ammonia solution, and the concentration of the substance in the reaction solution is about 0.10 mol / l.

[0028] (2) Microwave synthesis samples

[0029] Take the reaction solution in (1), add hexadecyltrimethylammonium bromide and tributyl phosphate in turn, stir evenly, put natural cotton into it, and treat it under microwave power 296w for 5 minutes until the natural cotton is transparently dispersed ; wherein the mass ratio of zinc nitrate, cetyltrimethylammonium bromide, tributyl pho...

Embodiment 3

[0033] (1) Preparation of zinc ammonia solution

[0034] Take the same volume of NaOH solution and zinc nitrate solution, slowly add the NaOH solution into the zinc nitrate solution, stir continuously, obtain a precipitate, vacuum filter, clean to obtain a pure zinc hydroxide precipitate, transfer the precipitate to a beaker, add dropwise 25 % ammoniacal liquor until the precipitation is completely dissolved, and the solution is clarified, and the solution is suction-filtered to obtain a zinc-ammonia solution, and the concentration of the substance in the reaction solution is about 0.15mol / l.

[0035] (2) Microwave synthesis samples

[0036] Take the reaction solution in (1), add hexadecyltrimethylammonium bromide and tributyl phosphate in turn, stir evenly, put natural cotton into it, and treat it under microwave power 296w for 5 minutes until the natural cotton is transparently dispersed ; wherein the mass ratio of zinc nitrate, cetyltrimethylammonium bromide, tributyl phos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com