Method for selectively preparing propylene glycol from sugar-containing compound

A compound and a technology for propylene glycol are applied in the field of selective preparation of propylene glycol, can solve problems such as inability to achieve, and achieve the effects of low cost, convenient use and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Preparation of activated carbon with basic functional groups: Soak the activated carbon with 10% KOH at a mass concentration of 80°C, dry it, and roast it in an inert atmosphere at 600°C for 1 hour to obtain AC-base for use.

[0030] Preparation of metal catalysts: impregnate activated carbon supports with basic functional groups with aqueous solutions of nickel nitrate, chloroplatinic acid, and ruthenium trichloride, dry at 120°C for 12h, and then reduce them in a hydrogen atmosphere at 450°C for 1h to obtain catalysts Ni / AC-base(5wt%Ni), Pt / AC-base(0.5wt%Pt), Ru / AC-base(5wt%Ru). Replace the basic activated carbon support with CaO, ZnO, Cs 2 O, La 2 o 3 , BaO, the same method can produce 5%Ru / CaO, 5%Ru / ZnO, 5%Ru / Cs 2 O, 5%Ru / La 2 o 3 , 5%Ru / BaO, 5%Ru / CaO catalyst; dilute the ruthenium trichloride solution 5 times, the same method can get 1%Ru / ZnO catalyst.

[0031] Other metals and catalysts with different loads used in the following examples were prepared by imp...

Embodiment 2

[0033] Cellulose catalytic conversion experiment: Add 1.0g cellulose, 0.3g metal ruthenium catalyst supported by alkaline carrier, 0.1g tungstic acid catalyst, 100ml water into a 200ml reactor, replace the gas with hydrogen gas three times, and fill it with hydrogen gas to 5MPa , be warming up to 240 DEG C of reaction 30min. After the reaction, cool down to room temperature, take the centrifuged supernatant, separate it on a high-performance liquid chromatography calcium-type ion-exchange column and detect it with a differential refraction detector. In the product yield, only the target products ethylene glycol, propylene glycol and hexahydric alcohols (including sorbitol and mannitol) are calculated, and other liquid products include butylene glycol, ethanol, unknown components, and gas products (CO 2 , CH 4 , C 2 h 6 etc.) The yield was not calculated.

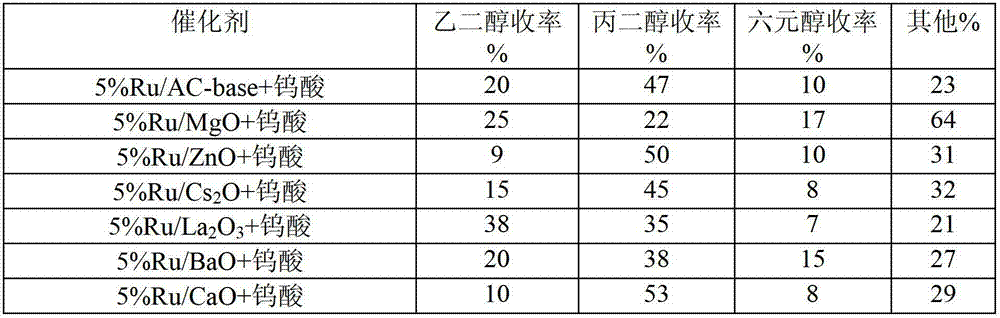

[0034] The catalytic conversion results of cellulose on various composite catalysts are shown below (Table 1).

[003...

Embodiment 3

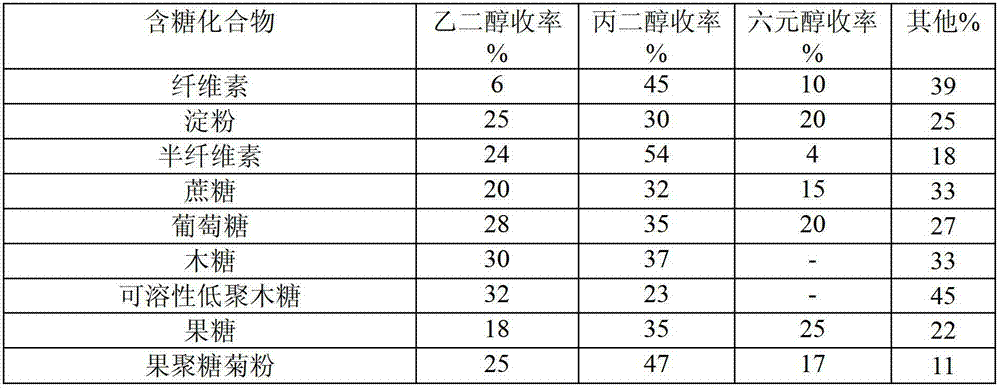

[0039] Add 5.0g of sugar-containing compound, 1.0g of 1%Ru / ZnO catalyst, 0.8g of tungstic acid catalyst, and 100ml of water into a 200ml reaction kettle. After replacing the gas with hydrogen gas three times, fill it with hydrogen gas to 5MPa, and heat up to 240°C for reaction. 30min. The catalytic conversion results of various sugar-containing compounds are shown below (Table 2).

[0040] Table 2 Results of catalytic conversion of various sugar-containing compounds on Ru / ZnO+tungstic acid catalyst

[0041]

[0042] As shown in Table 2, various sugar-containing compounds can be converted into propylene glycol with high selectivity in the catalytic process involved in the present invention.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com