Synthesis method of hydroxy-acetone using vanadium-based catalyst

A technology of hydroxyacetone and catalyst, which is applied in molecular sieve catalysts, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problems of high energy consumption for separation and low conversion rate of cellulose, and achieve low energy consumption for separation and excellent preparation process The effect of simplicity and good application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Beta molecular sieve dealumination: Weigh 20g of Hβ molecular sieve, 200mL of 12mol / L concentrated nitric acid, place in a 500mL three-neck flask, stir and reflux in a water bath at 80°C, dealuminate for 12h, wash until neutral, dry at 110°C for 24h, Raise the temperature to 550°C at a rate of ℃ / min, cool to room temperature after calcination for 4 hours, and obtain Hβ-deAl molecular sieves. V in the catalyst V / Hβ-deAl in the examples represents V 2 o 5 .

[0026] Catalyst Preparation: 1% V / Hβ-deAl Catalyst Preparation:

[0027] Dissolve 0.034g of vanadyl trichloride in 2ml of ethanol, add 1g of Hβ-deAl molecular sieve, stir well, dry at 80°C overnight, and then roast at 600°C for 3 hours to obtain 1% V / Hβ-deAl catalyst.

[0028] Prepare 0.5% V / Hβ-deAl, 2% V / Hβ-deAl, 4% V / Hβ-deAl catalysts by the same method.

[0029] 1%Ru / AC catalyst preparation:

[0030] 0.103g RuCl 3 Dissolve in 10ml of water, add 5g of activated carbon, stir and impregnate, dry at 80°C overnigh...

Embodiment 2

[0032] Glucose catalytic conversion experiment: add 45ml methanol, vanadium-based catalyst containing 0.012g vanadium, 0.30g 1% Ru / AC into a 100ml reactor, pass through nitrogen for three times, then pass through hydrogen for three times, fill the hydrogen to 3MPa, Raise the temperature to 220°C, inject 5ml of 50wt% glucose aqueous solution with a high-pressure constant-flow pump at a flow rate of 1ml / min, and continue the reaction for 30min after the injection. After the reaction, cool to room temperature, release the pressure and open the kettle. After the reaction solution is filtered, the yield of hydroxyacetone is analyzed on gas chromatography, and the conversion rate of glucose and the yield of sorbitol are analyzed on liquid chromatography.

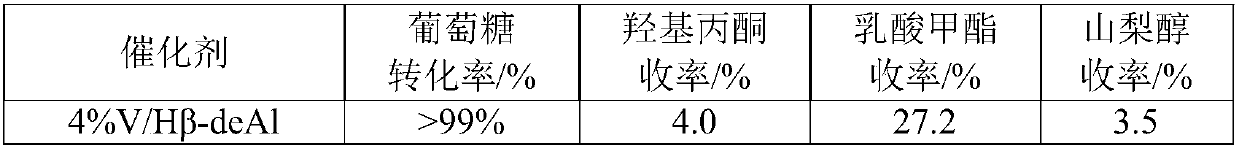

[0033]

[0034] The product yields in the table are all carbon yields, and the product carbon yield=the number of carbon moles in the product / the number of carbon moles in carbohydrates×100%.

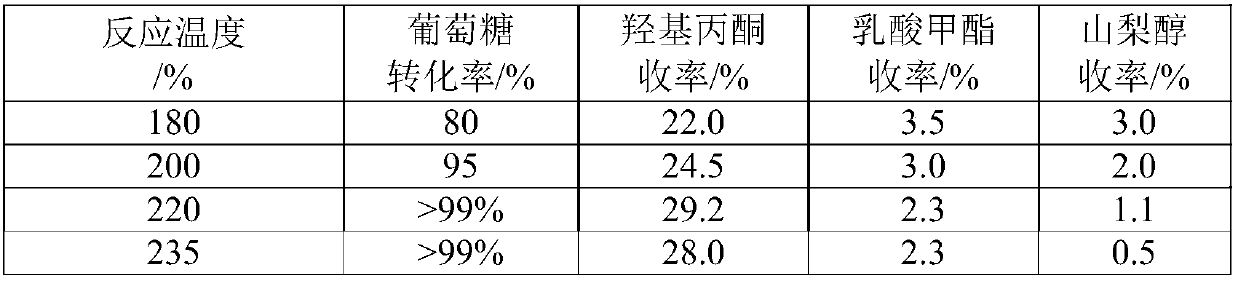

[0035] 1%Ru / AC-4%V / Hβ-deAl and 1%...

Embodiment 3

[0037]Glucose catalytic conversion experiment: Add 45ml of methanol, 4% V / Hβ-deAl catalyst containing 0.012g of vanadium, 0.30g of 1%Ru / AC into a 100ml reactor, pass through nitrogen for three times, and then pass through hydrogen for three times. Inflate hydrogen to 3MPa, heat up to the reaction temperature, inject 5ml of 50wt% glucose aqueous solution with a high-pressure constant-flow pump, flow rate is 1ml / min, and continue to react for 30min after the injection is completed. After the reaction, cool to room temperature, release the pressure and open the kettle. After the reaction solution is filtered, the yield of hydroxyacetone is analyzed on gas chromatography, and the conversion rate of glucose and the yield of sorbitol are analyzed on liquid chromatography.

[0038]

[0039] As can be seen from the data in the table, the highest yield of hydroxyacetone was obtained at 220°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com