A kind of vanadium-based catalyst is used for the synthetic method of hydroxyacetone

A technology of hydroxyacetone and catalyst, which is applied in molecular sieve catalysts, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problems of low cellulose conversion rate and high energy consumption for separation, and achieve simple preparation process and low energy consumption for separation , not easy to lose the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Beta-type molecular sieved aluminum: 20 g of Hβ molecular sieve, concentrated nitric acid in 200 ml of 12 mol / L, placed in a 500 ml of three flasks, mixed back through 80 ° C, de-release treatment for 12 h, washed to neutral, 110 ° C drying 24h, in 2 The rate of ° C / min was raised to 550 ° C, and after calcination 4 h, cooled to room temperature to obtain an Hβ-DEAL molecular sieve, and the catalyst V / Hβ-DEAL in the example V represents V 2 O 5 .

[0026] Catalyst Preparation: 1% V / Hβ-DEAL catalyst preparation:

[0027] 0.034 g of a trichloroxide was dissolved in 2 ml of ethanol, and 1 g of Hβ-DEAL molecular sieve was added, thoroughly stirred at 80 ° C overnight, and then baked at 600 ° C for 3 h, i.e., 1% V / Hβ-DEAL catalyst.

[0028] 0.5% V / Hβ-DEAL, 2% V / Hβ-DEAL, 4% V / Hβ-DEAL catalyst were prepared by the same method.

[0029] 1% RU / AC catalyst preparation:

[0030] Will 0.103G Rucl 3 In 10 ml of water, 5 g of activated carbon was added, and stirred with...

Embodiment 2

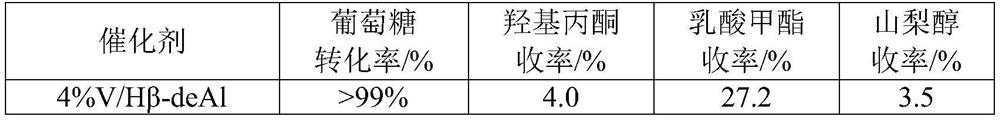

[0032] Glucose catalytic transformation experiment: 45 ml of methanol was added to a 100 ml reaction kettle, a vanadium-containing 0.012 g of a vanadium-based catalyst, 0.30 g 1% Ru / AC, and transferred in nitrogen and replaced three times, then transferred three times, charge hydrogen to 3 MPa, The temperature was raised to 220 ° C, and the 50 wt% glucose aqueous solution was injected with a high pressure constant current pump 5 mL, the flow rate was 1 ml / min, and the injection was continued after 30 min. After the reaction, it was cold to room temperature, the pressure relief is filtered, and the hydroxypropion yield was analyzed by the gas chromatography after filtration, and the glucose conversion and sorbitol yield were analyzed on liquid chromatography.

[0033]

[0034] The product yield in the table is carbon yield, product carbon yield = carbon molar number / carbohydrate in the product × 100%.

[0035] 1% RU / AC-4% V / Hβ-DEAL and 1% RU / AC-V 2 O 5 A preferred hyd...

Embodiment 3

[0037]Transformation of glucose catalytic transformation: 45 ml of methanol was added to a 100 ml reaction kettle, a 4% V / Hβ-DEAL catalyst containing 0.012 g of vanadium, 0.30 g 1% Ru / AC, and then inserted into a three times, and then transferred three times. Hydrogen was 3 MPa, warmed to the reaction temperature, injected 50 wt% glucose aqueous solution of 50 wt% glucose solution with a high pressure constant current pump, and continued to reflect 30 min after the flow rate of 1 ml / min. After the reaction, it was cold to room temperature, the pressure relief is filtered, and the hydroxypropion yield was analyzed by the gas chromatography after filtration, and the glucose conversion and sorbitol yield were analyzed on liquid chromatography.

[0038]

[0039] The data in the table can be seen that the highest hydroxypropionate yield is obtained at 220 ° C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com