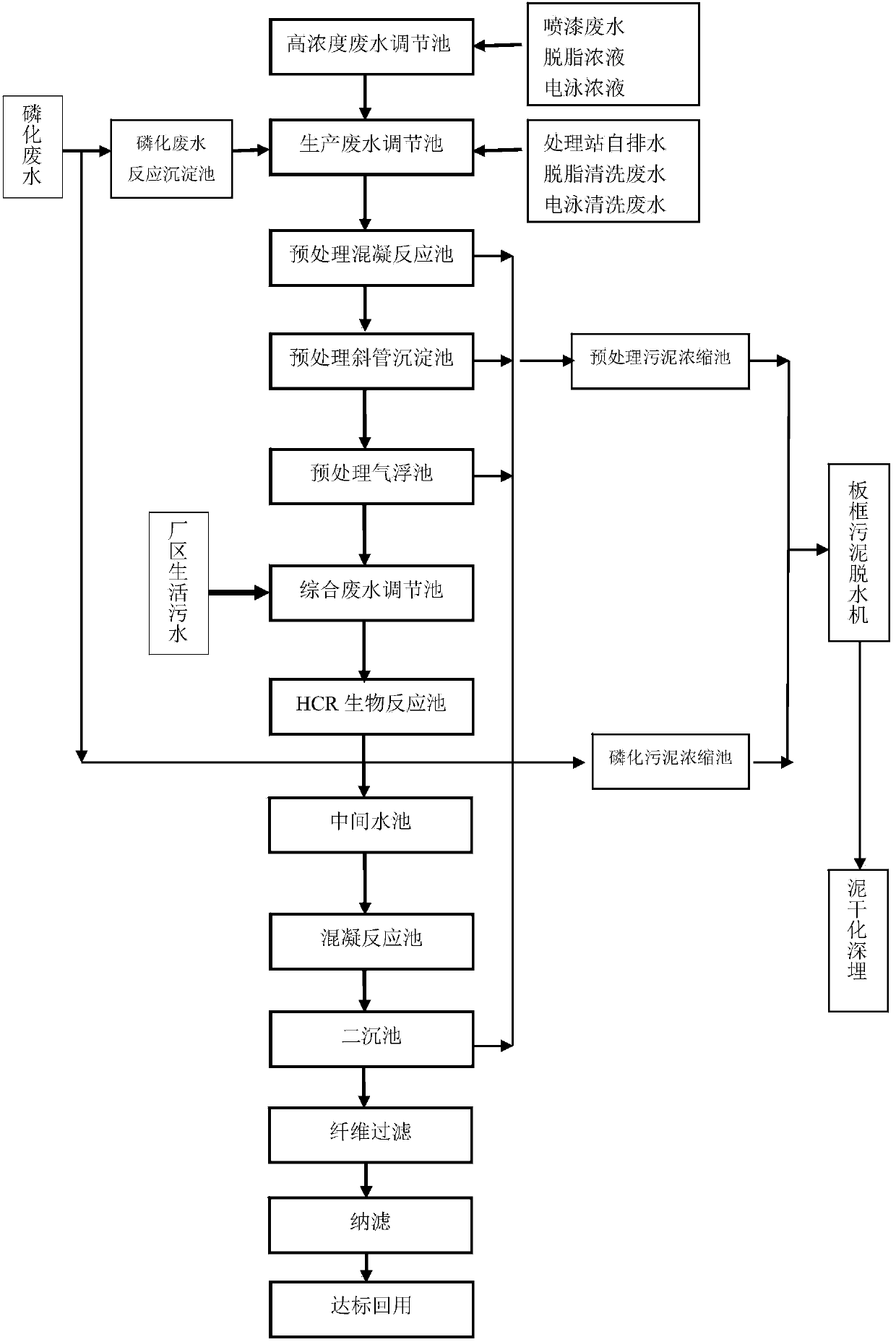

Recycling treatment method for automobile coating wastewater

A technology for coating wastewater and treatment methods, applied in the fields of water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0030] 1) Collect the waste water and waste liquid produced in the workshop in the phosphating pool or high-concentration waste water regulating pool respectively. The influent water quality: pH is 8.07, COD is 4078mg / L, BOD is 986mg / L, and total zinc is 42mg / L, total phosphorus 105mg / L, nickel 36mg / L.

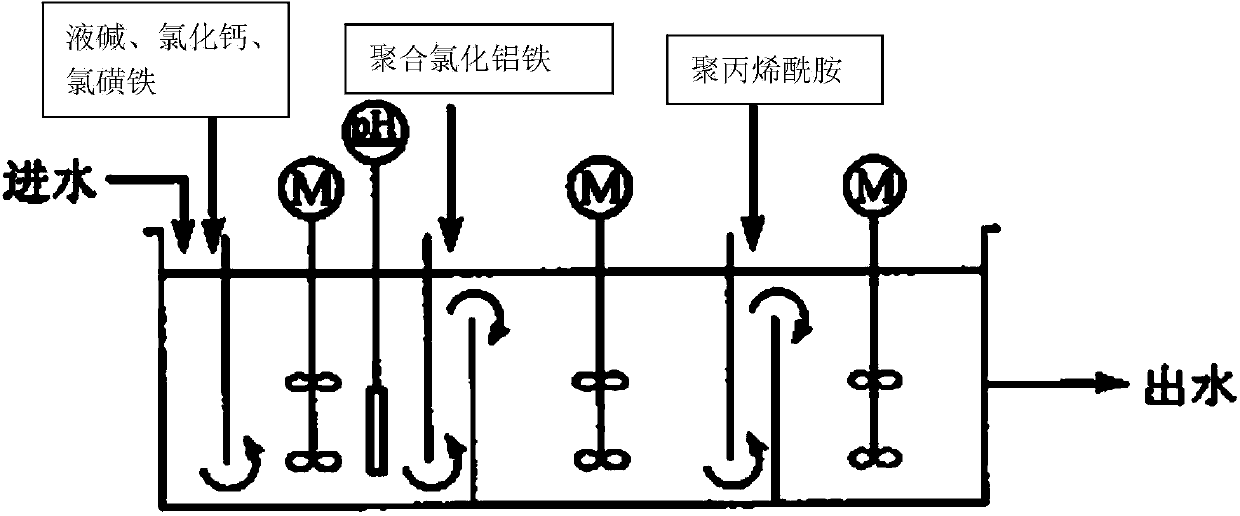

[0031] 2) Phosphating wastewater enters the phosphating wastewater reaction sedimentation tank for intermittent treatment, adding liquid caustic soda to adjust the pH value to 10.2, calcium chloride 800mg / l, chlorosulfuric iron 75mg / L, and anionic polyacrylamide 3mg / L for treatment , After 24 hours of standing still after treatment, the supernatant is discharged into the production wastewater adjustment tank, and the mud is discharged into the phosphating sludge concentration tank.

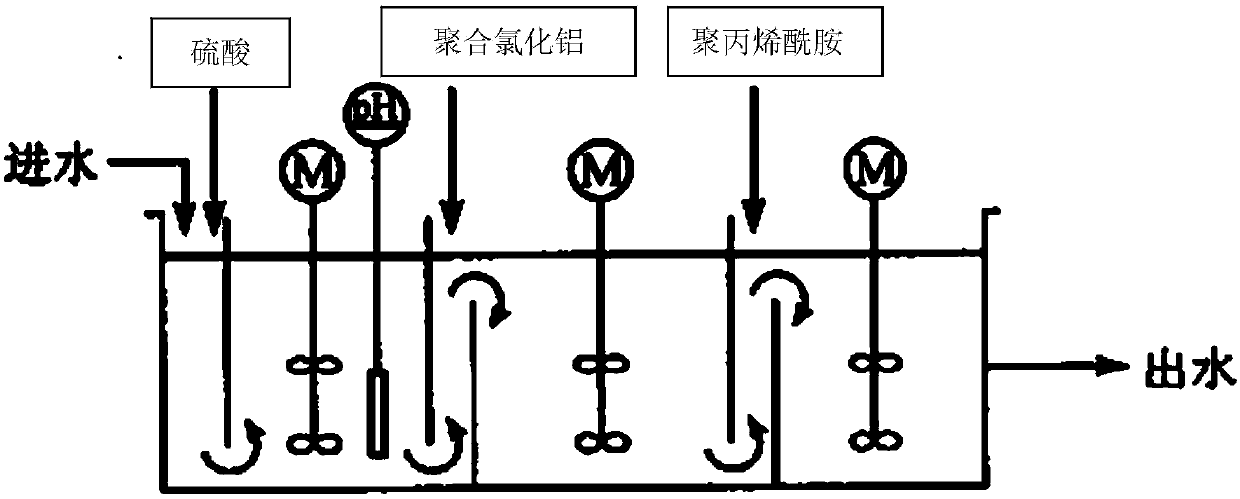

[0032] 3) A small amount of high-concentration wastewater is added to the production wastewater adjustment pool every day, and the water quality and quantity are adjusted with the treated phospha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com