Negative electrode material for alkaline secondary zinc electrode

A negative electrode material, zinc electrode technology, applied in alkaline batteries, electrode manufacturing, battery electrodes, etc., can solve the problems of calcium zincate not seen, long reaction time, etc., achieve small particle size, prolong life, and high electrochemical activity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

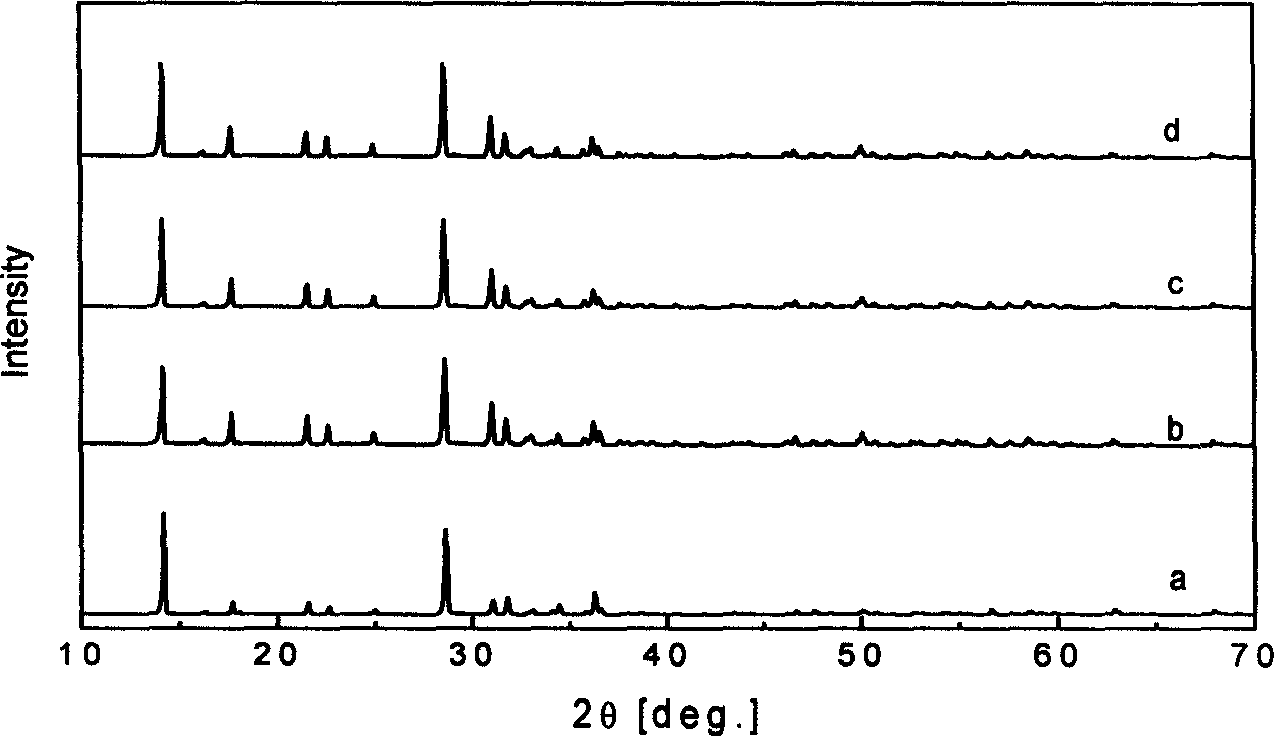

[0034] Embodiment 1: Synthesis of calcium zincate by high-energy ball milling

[0035] What the present invention used was the Fritsch P-6 planetary ball mill produced in Germany, and the main technical parameters are:

[0036] (1) Ball mill jar: made of stainless steel, 250ml

[0037] (2) Ball: made of stainless steel, there are two specifications: φ10mm (4g / piece) and φ20mm (32g / piece)

[0038] (3) Speed: 100~600 rpm

[0039] (4) Others: There are two ventilation holes on the lid of the tank, through which various gases can be introduced to control the atmosphere of the ball mill

[0040] Put 18.5 grams of 200-300 mesh calcium hydroxide powder and 40.5 grams of 200-300 mesh zinc oxide powder into the ball mill jar, and then add 18-20 grams of distilled water. According to the mass ratio of the ball to the material of 4:1, the quality of adding large (4) and small (47) stainless steel balls is 316 grams in total, and under the protection of argon, carry out solid phase syn...

Embodiment 2

[0042] 8 grams of 200-300 mesh calcium zincate, 0.8 grams of 200-300 mesh graphite powder and 0.10 grams of 200-300 mesh nano-titanium dioxide are mixed, bonded with polytetrafluoroethylene, and then the mixture is filled into the pores of foamed brass , After drying, press the two sides of the brass mesh current collector with a pressure of 20MPa, and the total thickness of the electrode is 2-3mm. Soak the zinc electrode in a 3.8 mol / l KOH solution containing saturated ZnO, and apply an overpotential of -200mV to the zinc electrode through a potentiostat (UK Solartron 1287). Under such conditions, the cathode is polarized for 3500 seconds, and the change of the current intensity with time before and after polarization (ie, the i~t curve) is observed, so as to judge the condition of the electrodeposited zinc. If the deposited zinc is relatively uniform and dense, it will not cause changes in the real surface area of the zinc electrode, and the current through the zinc electr...

Embodiment 3

[0044] 8 grams of 200-300 mesh calcium zincate, 0.8 grams of 200-300 mesh graphite powder and 0.10 grams of 200-300 mesh lanthanum trioxide are mixed, bonded with polytetrafluoroethylene, and then filled into the holes of foamed brass , After drying, press the two sides of the brass mesh current collector with a pressure of 20MPa, and the total thickness of the electrode is 2-3mm. Soak the zinc electrode in a 3.8 mol / l KOH solution containing saturated ZnO, and apply an overpotential of -200mV to the zinc electrode through a potentiostat (UK Solartron 1287). Under such conditions, the cathode was polarized for 600 seconds, and then the condition of the electrodeposited zinc was judged by SEM observation. Figure 5 It is a scanning electron micrograph (30 μm) of a calcium zincate electrode without adding dilanthanum trioxide. Figure 6 It is a scanning electron micrograph (30 μm) of a calcium zincate electrode added with dilanthanum trioxide. It can be seen that the zinc afte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com