Method for treating acid-washing wastewater and metallic ions in iron and steel industry

A technology for pickling wastewater and treatment methods, which is applied in chemical instruments and methods, multi-stage water/sewage treatment, water/sludge/sewage treatment, etc. and other problems, to achieve fast and stable interception, lower operating costs, and stable removal effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] The cold rolling pickling wastewater treatment project from the iron and steel industry is selected. The raw water quality of the pickling wastewater is as follows:

[0040] Phosphate root=300~350mg / L; COD≤300mg / L; pH≥1~2; total iron≤1500mg / L.

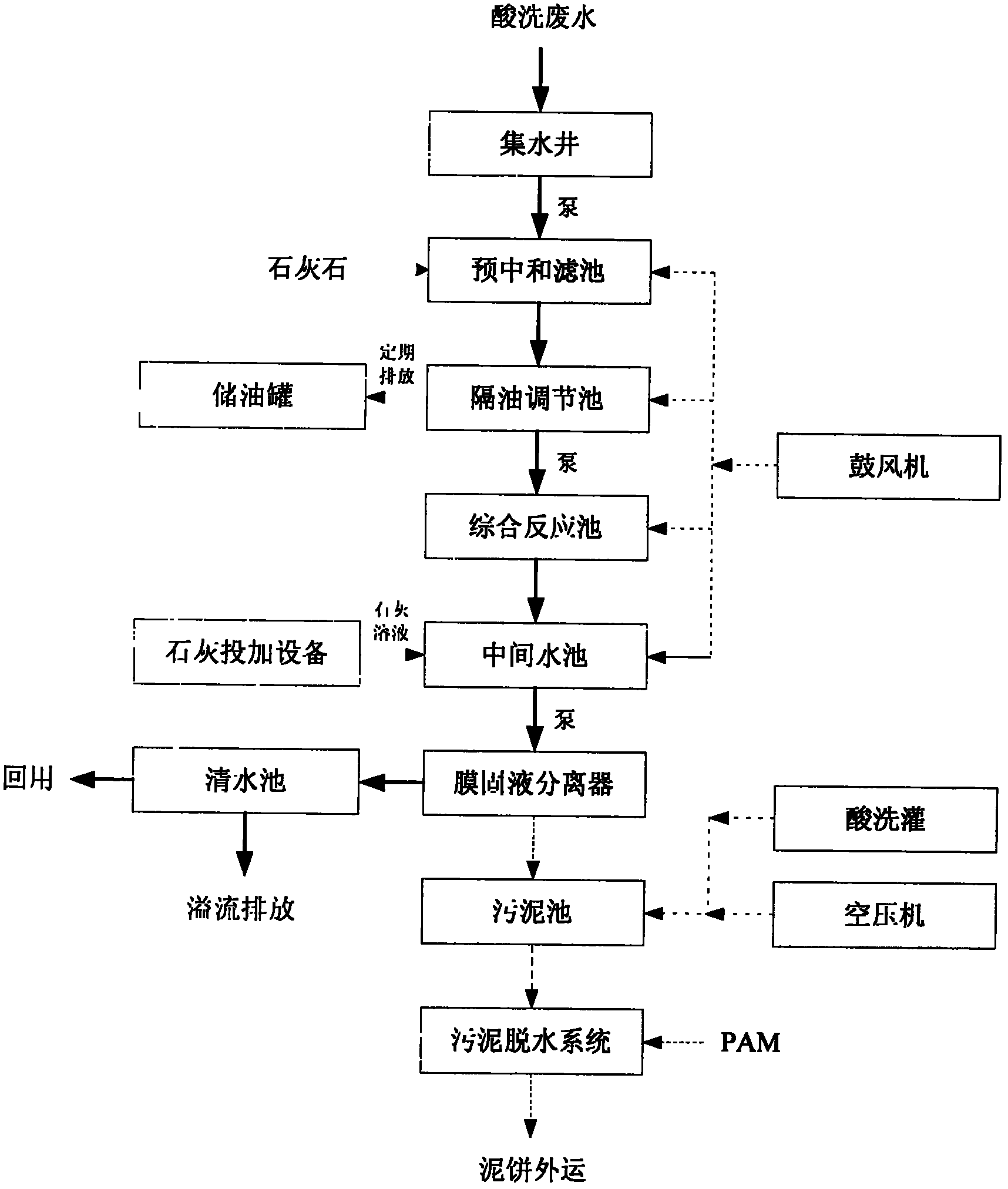

[0041] The implementation process of the present invention is described in detail in conjunction with accompanying drawings:

[0042] (1) The pH of the pickling wastewater is 2 when it enters the water. The wastewater flows into the collection well. The wastewater is lifted by the pump and enters the pre-neutralization filter. Limestone with a particle size of 10-100mm is set in the pre-neutralization filter. After the pickling wastewater is pre-neutralized with limestone, the pH of the effluent can be stabilized to about 6.

[0043] (2) After pre-neutralization, the pickling wastewater flows to the oil separation adjustment tank by itself. An oil-water separator is installed in the oil separation adjustment tank. The pickling...

Embodiment 2

[0053] The cold rolling pickling wastewater treatment project from the iron and steel industry is selected. The raw water quality of the pickling wastewater is as follows:

[0054] pH≥2; zinc≤45.8mg / L; total iron≤500mg / L

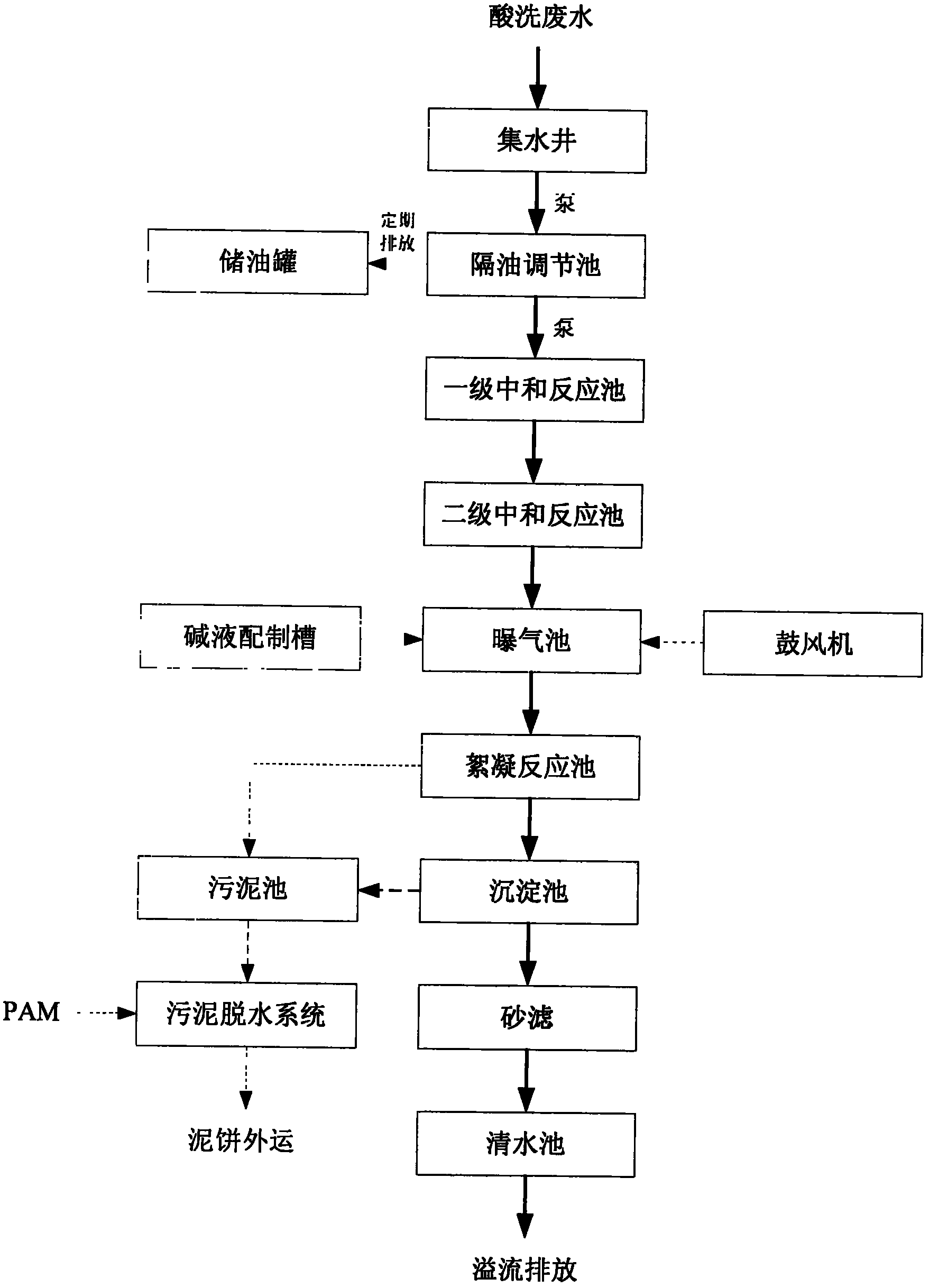

[0055] The implementation process of the present invention is described in detail in conjunction with accompanying drawings:

[0056] (1) The pH of the pickling wastewater is about 2 when it enters the water. The wastewater flows into the collection well. The wastewater is lifted by the pump and enters the pre-neutralization filter. Limestone with a particle size of 50-200mm is set in the pre-neutralization filter. Gradation distribution, after the pickling wastewater is pre-neutralized with limestone, the pH of the effluent can be stabilized to about 6.

[0057] (2) After pre-neutralization, the pickling wastewater flows to the oil separation adjustment tank by itself. An oil-water separator is installed in the oil separation adjustment tank. The pickling...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com