Preparation method for nano-zinc oxide modified graphene hybrid material

A technology of nano-zinc oxide and zinc hydroxide, applied in the direction of zinc oxide/zinc hydroxide, nanotechnology, nanotechnology, etc., can solve the problems of effectively controlling graphene agglomeration, achieve inhibition of agglomeration and overlapping, convenient operation, and energy The effect of low consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

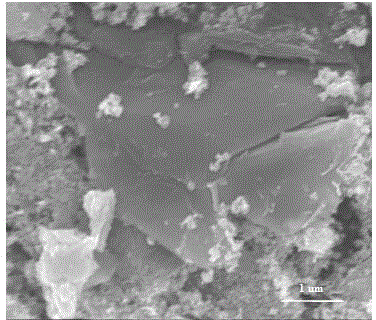

[0034] (1) Preparation of graphene oxide suspension: 0.5 g of graphite oxide was dispersed in water, ultrasonicated for 1 hour, and centrifuged to obtain a brownish yellow graphene oxide suspension.

[0035] (2) Preparation of zinc hydroxide-graphene oxide sol: 3.0g (0.01mol) of zinc sulfate is dissolved in distilled water to make a clear zinc sulfate aqueous solution, and added to the graphene oxide suspension prepared in step (1) Mix well. Afterwards, 0.735 g (0.021 mol) of ammonia water was added dropwise into the mixed solution, and continuously stirred and sonicated for 0.5 h to obtain a brown-yellow zinc hydroxide graphene oxide suspension.

[0036] (3) Preparation of zinc hydroxide-graphene gel: the zinc hydroxide-graphene oxide suspension prepared in step (2) was irradiated for 20min at an irradiation intensity of 10 joules / cm2, and aged for 12h at room temperature , to obtain a certain consistency of zinc hydroxide-graphene oxide gel. Then, excess tea polyphenols we...

Embodiment 2

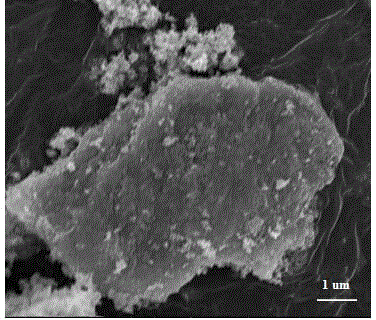

[0040](1) Preparation of graphene oxide suspension: 0.5 g of graphite oxide was dispersed in water, ultrasonicated for 1 hour, and centrifuged to obtain a brownish yellow graphene oxide suspension.

[0041] (2) Preparation of zinc hydroxide-graphene oxide sol: Dissolve 5.0g (0.0174mol) of zinc sulfate in distilled water to make a clear zinc sulfate aqueous solution, and add to the graphene oxide suspension prepared in step (1) Mix well. Afterwards, 1.3706g (0.03916mol) of ammonia water was added dropwise into the mixed solution, and continuously stirred and sonicated for 0.5h to obtain a brown yellow zinc hydroxide graphene oxide suspension.

[0042] (3) Preparation of zinc hydroxide-graphene gel: the zinc hydroxide-graphene oxide suspension prepared in step (2) was irradiated for 20min at an irradiation intensity of 10 joules / cm2, then aged for 12h at room temperature, A zinc hydroxide-graphene oxide gel with a certain consistency is obtained. Then, excess tea polyphenols w...

Embodiment 3

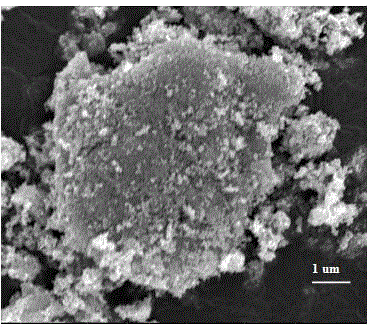

[0046] (1) Preparation of graphene oxide suspension: 0.5 g of graphite oxide was dispersed in water, ultrasonicated for 1 hour, and centrifuged to obtain a brownish yellow graphene oxide suspension.

[0047] (2) Preparation of zinc hydroxide-graphene oxide sol: Dissolve 8.0g (0.0279mol) of zinc sulfate in distilled water to make a clear zinc sulfate aqueous solution, and add to the graphene oxide suspension prepared in step (1) Mix well. Afterwards, 2.2460 g (0.06417 mol) of ammonia water was added dropwise into the mixed solution, and the mixture was continuously stirred and sonicated for 0.5 h to obtain a brown-yellow zinc hydroxide graphene oxide suspension.

[0048] (3) Preparation of zinc hydroxide-graphene gel: the zinc hydroxide-graphene oxide suspension prepared in step (2) was irradiated for 20min at an irradiation intensity of 10 joules / cm2, then aged for 12h at room temperature, A zinc hydroxide-graphene oxide gel with a certain consistency is obtained. Then, exce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com