Activated carbon-loaded nano-zinc oxide ozonation catalyst and preparation and use thereof

A nano-zinc oxide, ozone oxidation technology, applied in metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, chemical instruments and methods, etc., can solve problems such as catalyst loss, achieve efficient adsorption, good The effect of catalytic ozone oxidation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

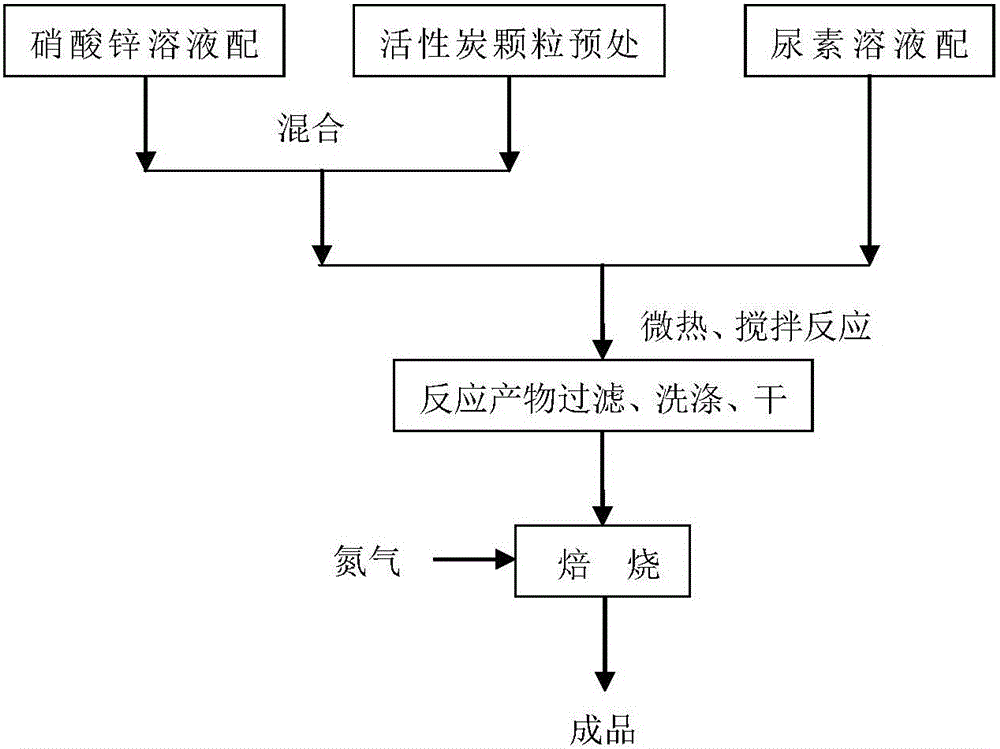

[0018] Weigh 600g of zinc nitrate and prepare a saturated solution; weigh 350g of urea and dissolve it in 3150g of distilled water; select 2-3mm activated carbon particles and soak them in 10% sodium hydroxide solution for 12 hours, and wash them with distilled water until the pH value of the cleaning solution reaches Until it changes again, soak it in 10% nitric acid for 3 hours, wash it with distilled water, and dry it for later use. First add the dried pretreated activated carbon particles into the above-mentioned zinc nitrate solution, heat to 40°C, and then add the prepared urea solution while stirring for 8 hours. After the reaction, the product was filtered, washed and dried, and sent to a horse boiler, and roasted in a nitrogen atmosphere at 600°C for 3 hours to obtain a finished catalyst.

Embodiment 2

[0020] Weigh 300g of zinc nitrate and make a saturated solution; weigh 200g of urea and dissolve it in 800g of distilled water; pick 2-3mm activated carbon particles and soak them in 5% sodium hydroxide solution for 20 hours, and wash them with distilled water until the pH value of the cleaning solution reaches Until it changes again, soak it in 10% nitric acid for 4 hours, wash it with distilled water, and dry it for later use. First add the dried pretreated activated carbon particles into the above-mentioned zinc nitrate solution, heat to 50°C, and then add the prepared urea solution while stirring and reacting for 6 hours. After the reaction, the product was filtered, washed and dried, and sent to a horse boiling furnace, and roasted for 3 hours in a nitrogen atmosphere at 500°C to obtain a finished catalyst.

Embodiment 3

[0022] Weigh 900g of zinc nitrate and prepare a saturated solution; weigh 600g of urea and dissolve it in 2400g of distilled water; pick 2-3mm activated carbon particles and soak them in 10% sodium hydroxide solution for 16 hours, and wash them with distilled water until the pH value of the cleaning solution reaches Until it changes again, soak it in 8% nitric acid for 5 hours, wash it with distilled water, and dry it for later use. First add the dried pretreated activated carbon particles into the above-mentioned zinc nitrate solution, heat to 40°C, and then add the prepared urea solution while stirring for 8 hours. After the reaction, the product was filtered, washed and dried, and sent to a horse boiler, and roasted for 4 hours in a nitrogen atmosphere at 600°C to obtain a finished catalyst.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com